Small-sized tobacco leaf shearing device

A technology for cutting shreds and tobacco leaves, which is applied to the field of small tobacco leaf shredding devices, and can solve the problems of unsatisfactory shredding effect, clumps of filaments, and broken leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

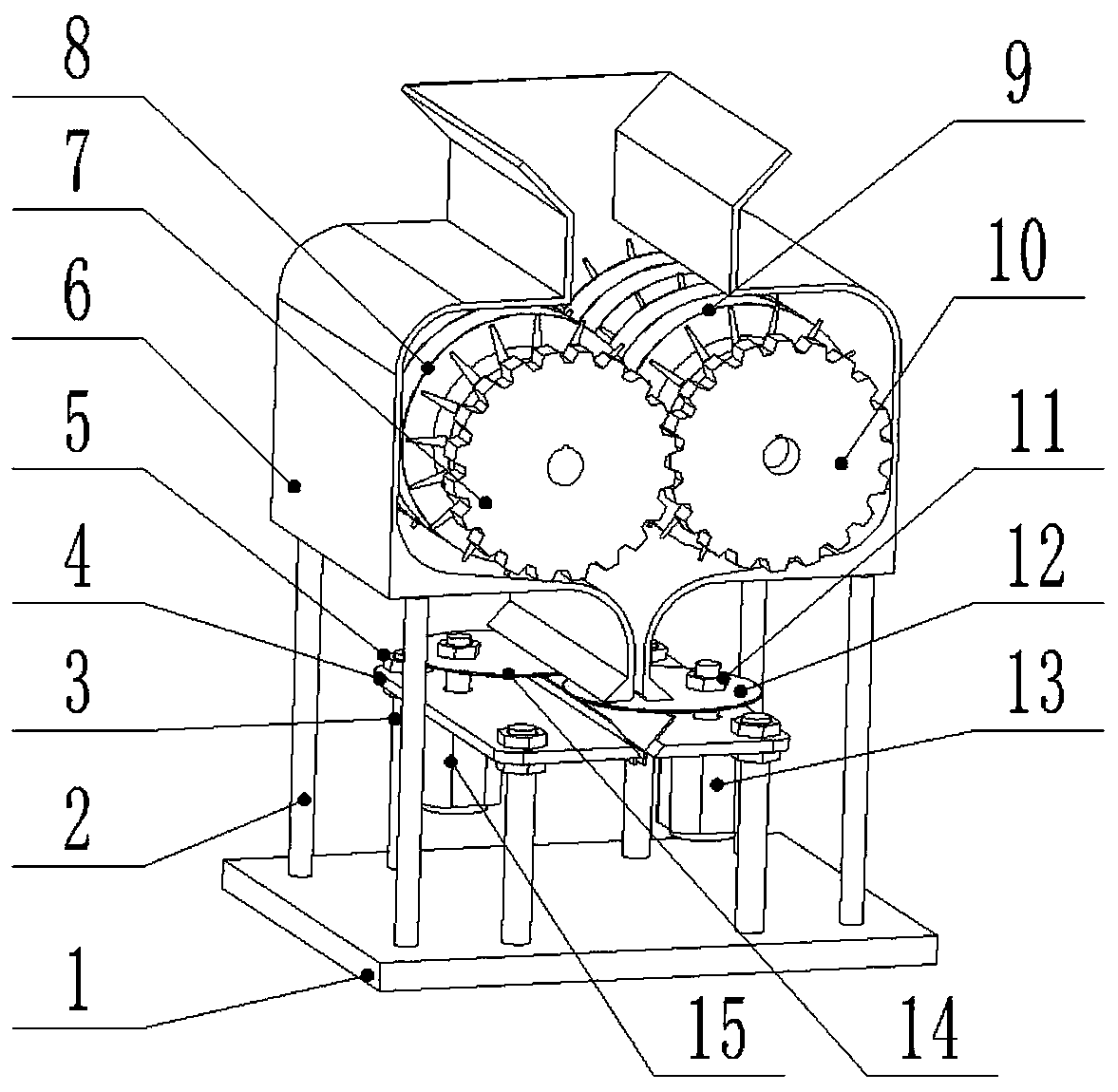

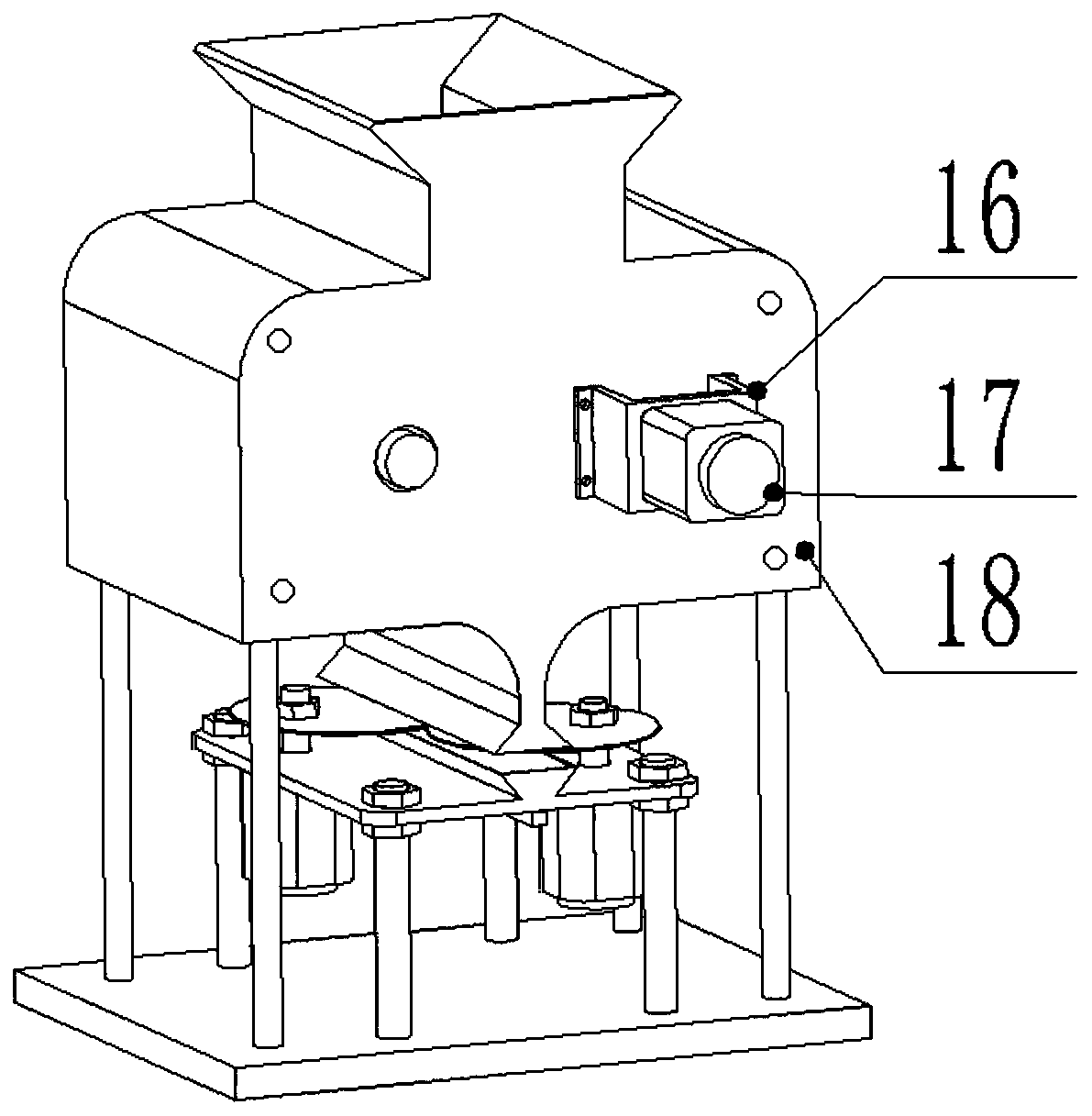

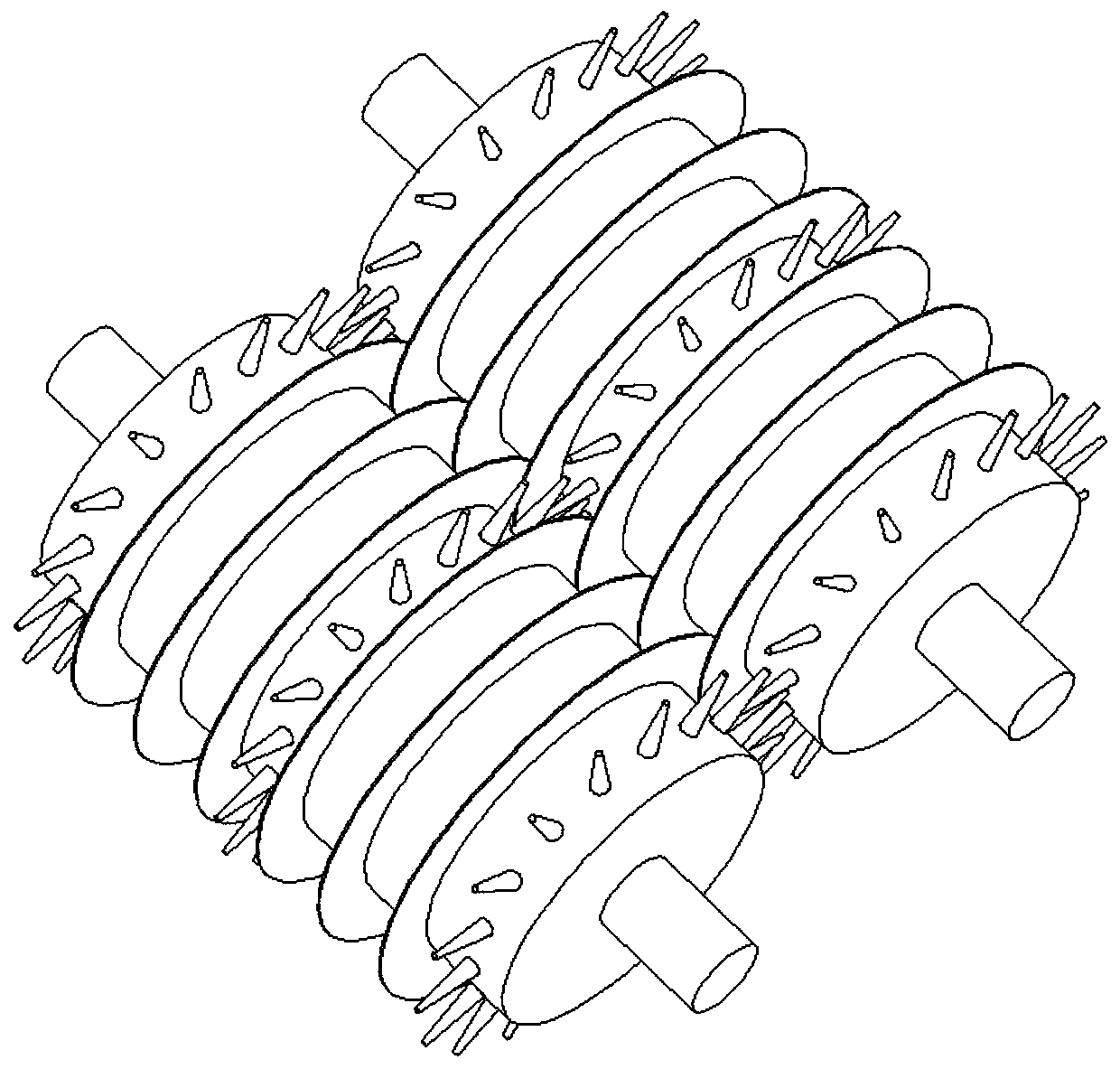

[0008] A small tobacco leaf cutting device is composed of a base 1, a support rod 2, an adjustment rod 3, a cut wire collecting rack 4, a mounting nut 5, a feeding casing 6, a driving gear 7, a main feeding blade cutting hob 8, an auxiliary Feeding leaf shearing hob 9, driven gear 10, lock nut 11, first eccentric blade 12, first slow motor 13, second eccentric blade 14, second slow motor 15, motor mounting frame 16, It is composed of a slow-speed feeding motor 17 and an unwinding casing cover 18. It is characterized in that the base is the carrier of the whole device, and the support rod 2 is connected and installed on the base 1 with an interference shaft hole. At the same time, the support rod 2 also has a shaft hole structure. The interference and discharge casing 6 is installed together, the two ends of the adjustment rod 3 are processed into a threaded structure, the adjustment rod 3 and the base 1 are threaded, the four corners of the cut wire collection frame 4 have thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com