Method for preparing CoNi-S-coated 3D-C nano composite material and modified battery diaphragm

A nano-composite material, coni-s technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of inability to maintain high-capacity lithium-sulfur batteries, low capacity, volume expansion of transition metal sulfides, etc. problem, to achieve good energy storage effect, high capacity and service life, and the effect of inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

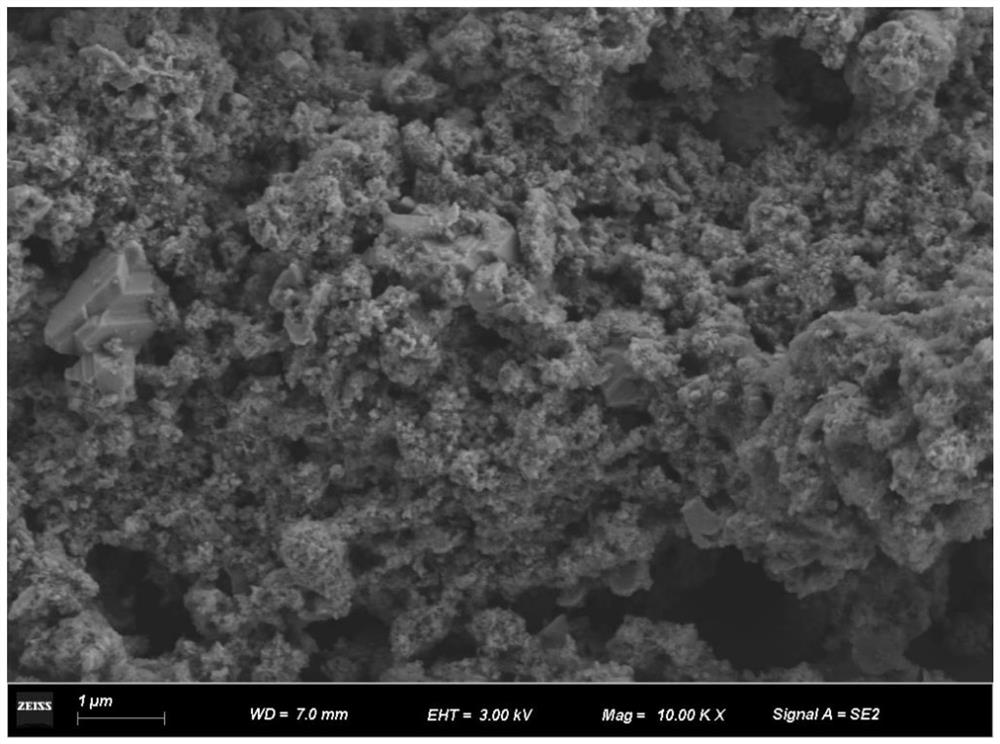

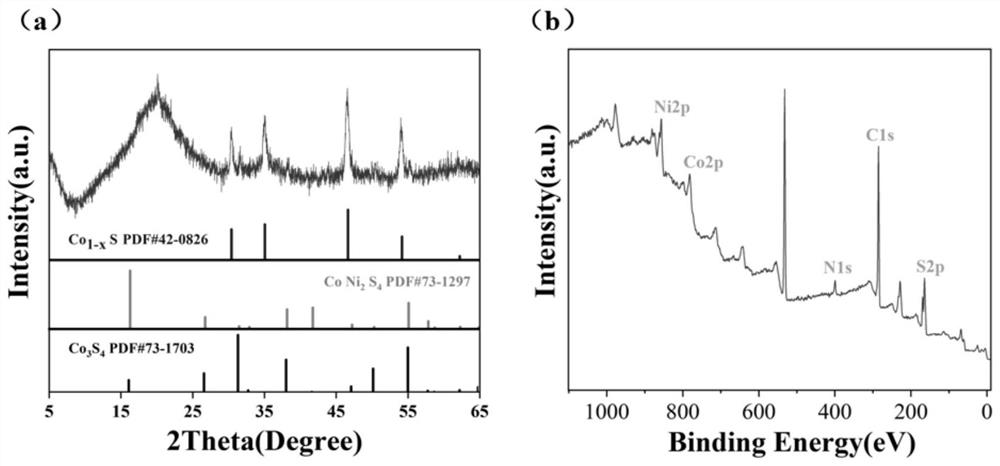

[0027] Example 1: Preparation of CoNi-S@3D-C nanocomposites

[0028] 0.48g cobalt nitrate powder, 0.48g nickel nitrate powder, 0.22g thiourea (CH 4 N 2 S) The powder was dissolved in 70 ml of ethylene glycol solution by ultrasonic stirring, and the ultrasonic stirring was continued for 30 minutes, after which 1.4 g of cetyltrimethylammonium bromide (CATB) powder and 0.422 g of glucose (C 6 H 12 O 6 ) solution, continue to keep ultrasonic stirring for 30 minutes, then transfer the above solution into a stainless steel autoclave, hydrothermally react at 180 ° C for 12 hours, the product is washed 3 times with deionized water and ethanol, and then dried at 80 ° C overnight. The good powder and sulfur powder are mixed in a mass ratio of 1:5 (100 mg of product: 500 mg of sulfur powder), then fully ground, and then placed in a high-temperature resistant porcelain boat, and heated to a temperature of 3 °C / min in a tube furnace. The final product CoNi-S@3D-C was obtained after hol...

Embodiment 2

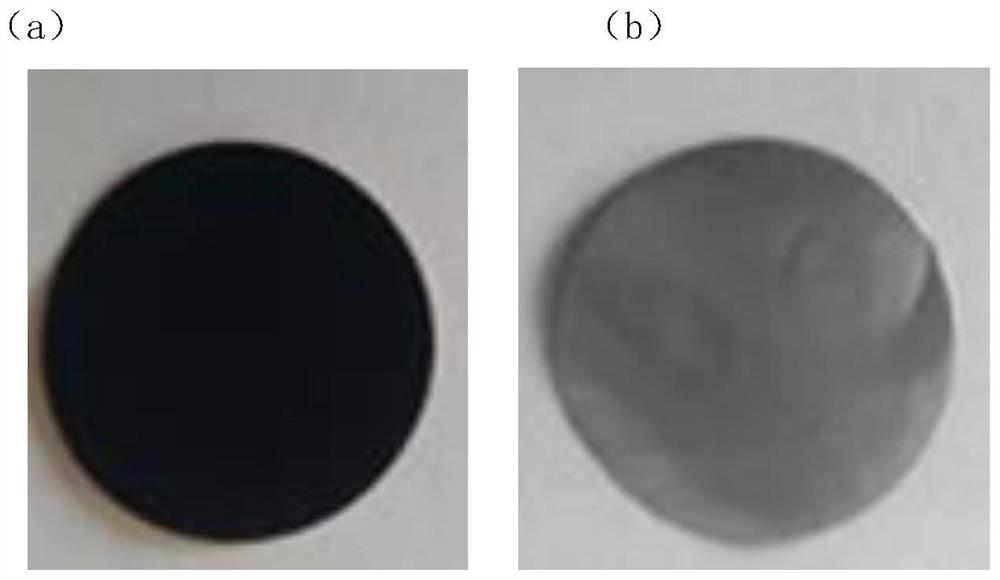

[0031] Example 2: Preparation of electrodes

[0032] 70 mg of CoNi-S@3D-C powder and 20 mg of acetylene black powder and 10 mg of polyvinylidene fluoride (PVDF) solution were mixed together, and the mixture was dispersed in N-methylpyrrolidone (NMP), triturated with agate The bowl is ground into a uniform slurry, which is then evenly coated on the copper foil. Then the coated copper foil was dried in a vacuum oven at a temperature of 70 °C for 12 hours, and cut into electrodes with a radius of 6 mm, such as image 3 As shown, 3a is the front side of the electrode and 3b is the back side of the electrode.

Embodiment 3

[0033] Example 3: Preparation of Li-ion and Na-ion batteries

[0034] Metal lithium and metal sodium were used as positive electrodes respectively, the electrodes obtained in Example 2 were used as negative electrodes, and Celgard 2325 commercial separators were used to assemble two button batteries, lithium ion batteries and sodium ion batteries, in the glove box. The lithium ion battery was added with 60 microliters The electrolyte used in lithium ion batteries is secondary electrolyte (LB-008); 80 microliters of electrolyte is added for sodium ion batteries, and sodium trifluoromethanesulfonate electrolyte (NS-001) is used in sodium ion batteries. The discharge capacities of the two batteries were measured at current densities of 100, 300, 500, 1000, and 2000 mA / g, respectively, such as Figure 4 (b) and (d), these two figures show that the discharge capacities of Li-ion batteries are 1096, 980, 891, 768 and 618 mAh / g at current densities of 100, 300, 500, 1000, 2000 mA / g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com