Aluminum electrolytic capacitor for liquid cooling power supply and preparation method thereof

An aluminum electrolytic capacitor and power supply technology, applied in the field of capacitors, can solve the problems of accelerated electrolyte decomposition, end of service life of capacitors, leakage, etc., and achieve the effect of excellent durability and stable leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

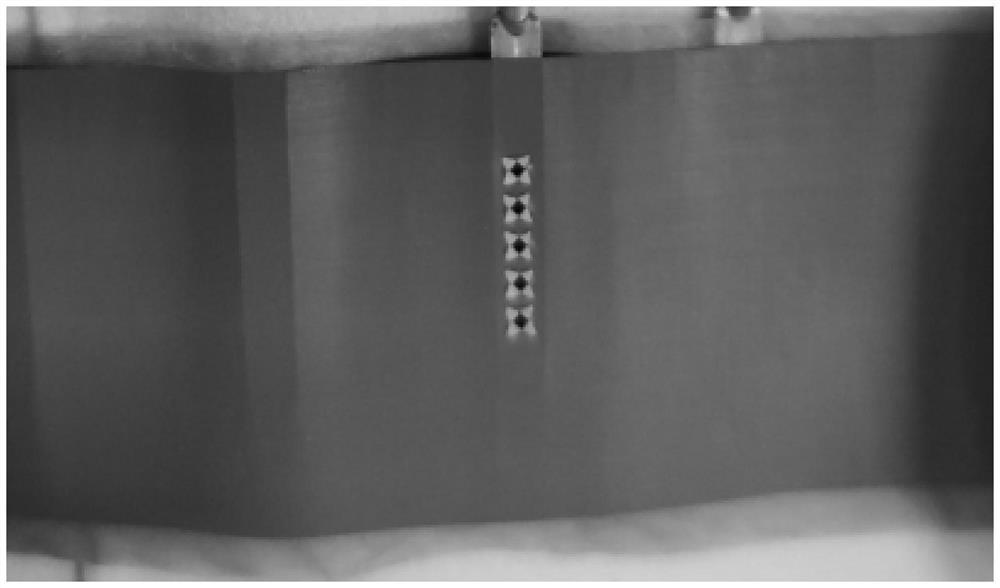

Image

Examples

Embodiment 1

[0043] This embodiment provides an aluminum electrolytic capacitor for liquid cooling power supply, which includes a casing, a core pack and a driving electrolyte disposed in the casing, and the core pack is made of electrolytic paper between the anode foil and the cathode foil. coiled.

[0044] Wherein, the driving electrolyte is composed of the following components by percentage: 55% solvent, 35% solute and 10% additive;

[0045] The solvent is composed of the following components in percentage: γ-hydroxybutyric acid lactone 58%, γ-butylpropyl ester 28%, ethylene glycol 10%, benzyl alcohol 4%; the solute is composed of the following components in percentage: Ammonium diacid 40%, ammonium l,10-dodecanedioic acid 28%, ammonium formate 15.2%, ammonium maleate 8%, borate 8%, branched chain carboxylate 0.8%; the additives are composed of the following components Composition by percentage: ammonium dihydrogen phosphate 62%, polymeric borate 14%, alkoxy 9%, chromic anhydride 12%, ...

Embodiment 2

[0059] Example 2 is basically the same as Example 1, except that the driving electrolyte is composed of the following components in percentage: 67% solvent, 20% solute and 13% additive;

[0060] The solvent is composed of the following components in percentage: γ-hydroxybutyric acid lactone 50%, γ-butyl propyl ester 34%, ethylene glycol 14%, benzyl alcohol 2%; the solute is composed of the following components in percentage: Ammonium diacid 50%, 1,10-dodecanedioic acid ammonium 18%, ammonium formate 16%, ammonium maleate 10%, borate 4.7%, branched chain carboxylate 1.3%; the additives are composed of the following components Composition by percentage: ammonium dihydrogen phosphate 58%, polymeric borate 21%, alkoxy 14%, chromic anhydride 5.2%, molybdic acid 1%, polymeric fatty acid 0.8%;

[0061] During the preparation process, 15% ammonium sebacate, 2% phosphoric acid and 83% water were mixed into a treatment solution, and the electrode foil was immersed in the treatment solut...

Embodiment 3

[0065] Example 3 is basically the same as Example 1, except that the driving electrolyte is composed of the following components in percentage: 45% solvent, 38% solute and 17% additive;

[0066] The solvent is composed of the following components in percentage: γ-hydroxybutyric acid lactone 62%, γ-butyl propyl ester 25%, ethylene glycol 8%, benzyl alcohol 5%; the solute is composed of the following components in percentage: Ammonium diacid 48%, 1,10-dodecanedioic acid ammonium 25%, ammonium succinate 10%, ammonium maleate 9%, borate 7%, branched chain carboxylate 1%; the additives are composed of The following components are composed by percentage: ammonium dihydrogen phosphate 45%, polymeric borate 25%, alkoxyl 16%, chromic anhydride 11.5%, molybdic acid 0.5%, polymeric fatty acid 2%.

[0067] In the preparation process, 10% ammonium sebacate, 3% phosphoric acid and 87% water were mixed into a treatment solution, and the electrode foil was immersed in the treatment solution f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com