Method for detecting taurine content in formula milk powder for special medical purpose

A technology of formula milk powder and detection method, which is applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problems of incomplete taurine derivatization reaction, large relative standard deviation, inability to accurately quantify taurine content, etc., and achieve shortened column Effects of pre-derivation time, high accuracy, fast derivation speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

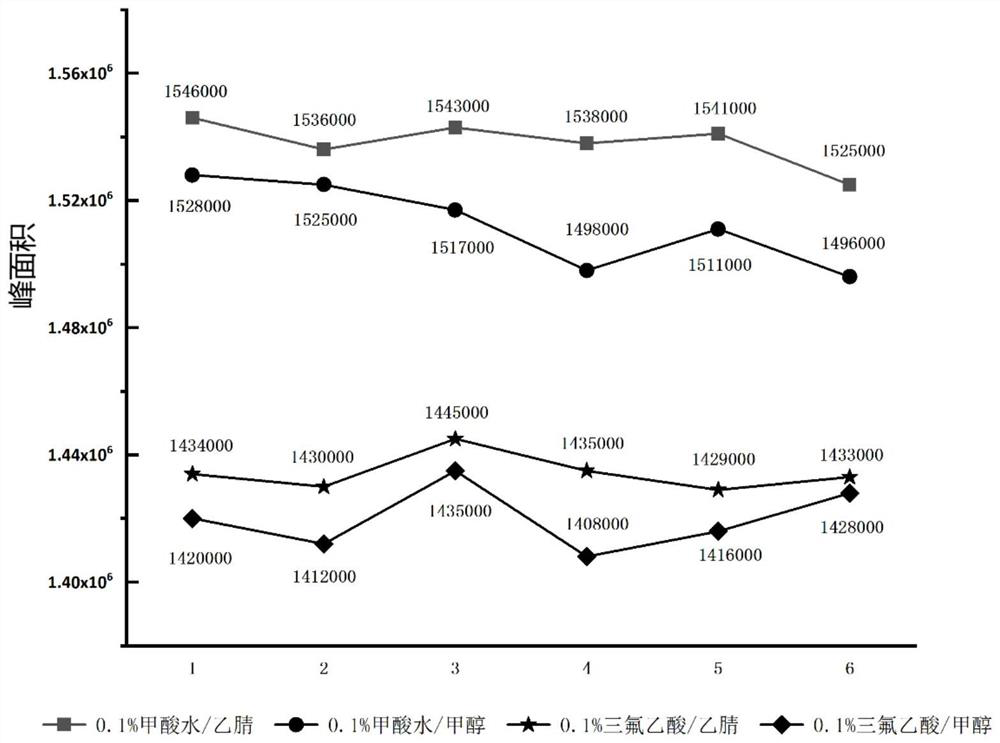

[0043] Example 1 Selection and optimization of detection methods

[0044] 1. Preparation of standard working solution

[0045] Accurately weigh 100.0 mg of taurine standard in a 100 mL volumetric flask, and prepare a standard stock solution with a concentration of 1.0 mg / mL using water as a solvent. Before the experiment, the standard stock solution was diluted with water into standard working solutions with concentrations of 1.0, 5.0, 10.0, 15.0, and 20.0 μg / mL.

[0046] 2. Extract taurine from the milk powder sample to be tested: accurately weigh 1.00±0.05g milk powder sample into a 50mL polytetrafluoroethylene plastic centrifuge tube, add about 35mL ultrapure water, ultrasonicate for 15min, and add 1mL 150g / L ferrocyanide The potassium chloride solution and 1 mL of 300 g / L zinc acetate solution were vortexed for 5 min to uniformly mix to remove the protein in the matrix, centrifuged at 9000 r / min for 2 min, and the supernatant was transferred to a 50 mL volumetric flask, a...

Embodiment 2

[0061] Example 2 Influence of different DNS-CL derivative liquid concentrations

[0062] In this example, the whole amino acid hydrolyzed formula milk powder is used as the sample to be tested, and the theoretical addition amount of taurine in the sample is 40.0 mg / 100 g. The sample was extracted and derivatized using the method in Example 1, and the prepared sample-derived product was detected by a two-dimensional liquid phase system. In this example, by changing the concentration of the derivatization reagent DNS-CL derivative solution, the effect of the concentration of the derivatization reagent on the detection of the taurine content in the milk powder samples for special medical care was investigated. The sample processing and detection methods are the same as in Example 1, except that the concentrations of the DNS-CL derivative solutions of different groups are set. Considering that the solubility of DNS-CL in acetonitrile is 50 mg / mL, the concentrations of the DNS-CL d...

Embodiment 3

[0066] Example 3 The influence of the pH value of the derived environment

[0067] During the reaction of taurine with DNS-CL, with the fluorescent product dansyl-aminoethanesulfonic acid DNS-NH-(CH 2 ) 2 –SO 3 Generation of H, Cl on DNS-CL - with H + Combined with HCl, it reduces the pH of the solution and inhibits the reaction in the positive direction. Therefore, during the derivatization process, it is necessary to keep the solution system in an alkaline environment. In this experiment, the whole amino acid hydrolyzed formula milk powder was also used as the sample to be tested, and the theoretical addition amount of taurine in the milk powder sample was 40.0 mg / 100 g. The method in Example 1 was used to extract and derivatize the sample, and the product derived from the sample was prepared and detected by a two-dimensional liquid phase system. The sample processing and detection methods are the same as those in Example 1, the difference is that the pH of the derivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com