Preparation process of champagne gold coating film

A preparation process and golden technology, which is applied in the field of preparation technology of champagne gold coating, can solve the problems of increasing defective rate, easy color deviation, and increased processing requirements, and achieves the effect of ensuring good product rate, improving processing quality and low color deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

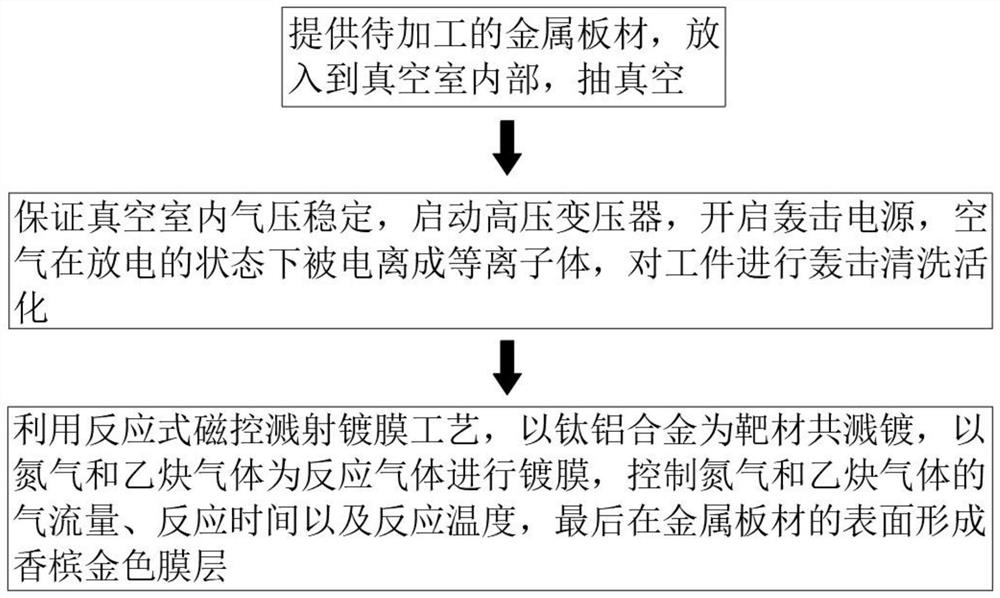

[0024] see Figure 1-2 , the present invention provides a technical scheme: the preparation process of champagne gold coating, comprising the following steps:

[0025] S1: Provide the metal sheet to be processed, put it into the vacuum chamber, and vacuumize the vacuum chamber. During the vacuuming process, ensure that the indoor air pressure is 6 -1 Pa, while the coating process remains unchanged;

[0026] S2: Ensure that the air pressure in the vacuum chamber is stable, start the high-voltage transformer, turn on the bombardment power supply, and control the current value within the range of 30 A. The air is ionized into plasma in the state of discharge, and the workpiece is bombarded, cleaned and activated;

[0027] S3: Use the reactive magnetron sputtering coating process to co-sputter with titanium and aluminum alloys as the target, and use nitrogen and acetylene gas as the reactive gas for coating. The reaction time is 120 minutes and the reaction temperature is 100 de...

Embodiment 2

[0030] The preparation process of champagne gold coating includes the following steps:

[0031] S1: Provide the metal sheet to be processed, put it into the vacuum chamber, and vacuumize the vacuum chamber. During the vacuuming process, ensure that the indoor air pressure is 6 -1 Pa, while the coating process remains unchanged;

[0032] S2: Ensure that the air pressure in the vacuum chamber is stable, start the high-voltage transformer, turn on the bombardment power supply, and control the current value within the range of 38 A. The air is ionized into plasma in the state of discharge, and the workpiece is bombarded, cleaned and activated;

[0033] S3: Use the reactive magnetron sputtering coating process to co-sputter with titanium and aluminum alloys as the target, and use nitrogen and acetylene gas as the reactive gas for coating. The reaction time is 120 minutes and the reaction temperature is 100 degrees Celsius, and finally a champagne gold film is formed on the surface...

Embodiment 3

[0036] The preparation process of champagne gold coating includes the following steps:

[0037] S1: Provide the metal sheet to be processed, put it into the vacuum chamber, and vacuumize the vacuum chamber. During the vacuuming process, ensure that the indoor air pressure is 6 -1 Pa, while the coating process remains unchanged;

[0038] S2: Ensure that the air pressure in the vacuum chamber is stable, start the high-voltage transformer, turn on the bombardment power supply, and control the current value within the range of 38 A. The air is ionized into plasma in the state of discharge, and the workpiece is bombarded, cleaned and activated;

[0039] S3: Use the reactive magnetron sputtering coating process to co-sputter with titanium and aluminum alloys as the target, and use nitrogen and acetylene gas as the reactive gas for coating. The reaction time is 120 minutes and the reaction temperature is 100 degrees Celsius, and finally a champagne gold film is formed on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com