Antiskid rubber gloves and processing method thereof

A technology of anti-slip rubber and processing method, which is applied in the direction of protective clothing and coatings, can solve the problems of reducing the protective effect of gloves and yield, uneven surface thickness of finished gloves, and small holes in gloves, etc., to improve the anti-slip effect, Good anti-slip effect and improved grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

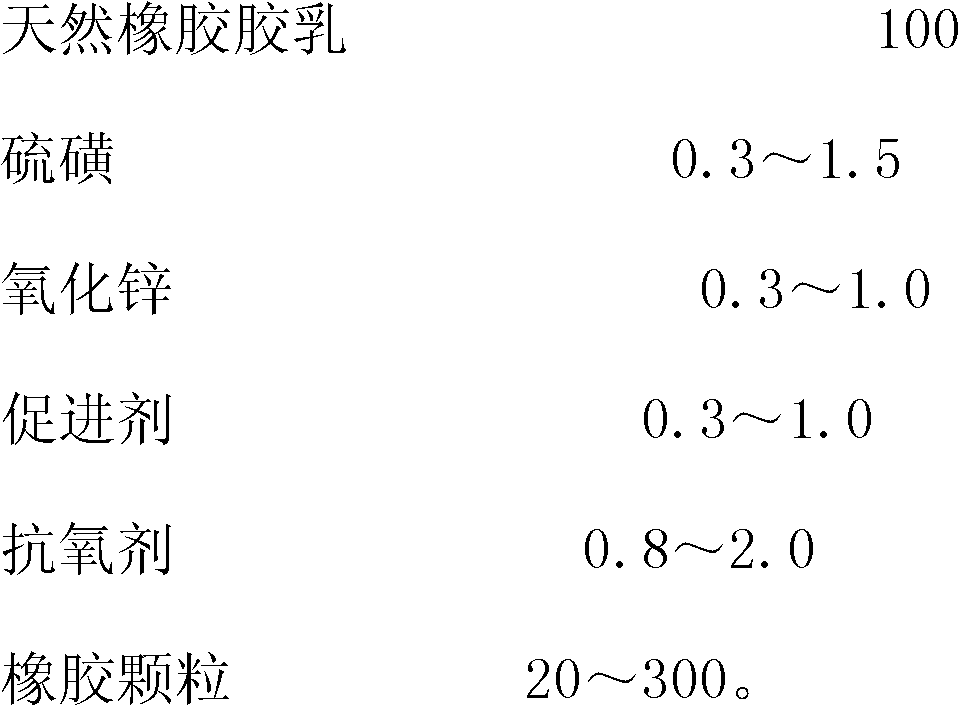

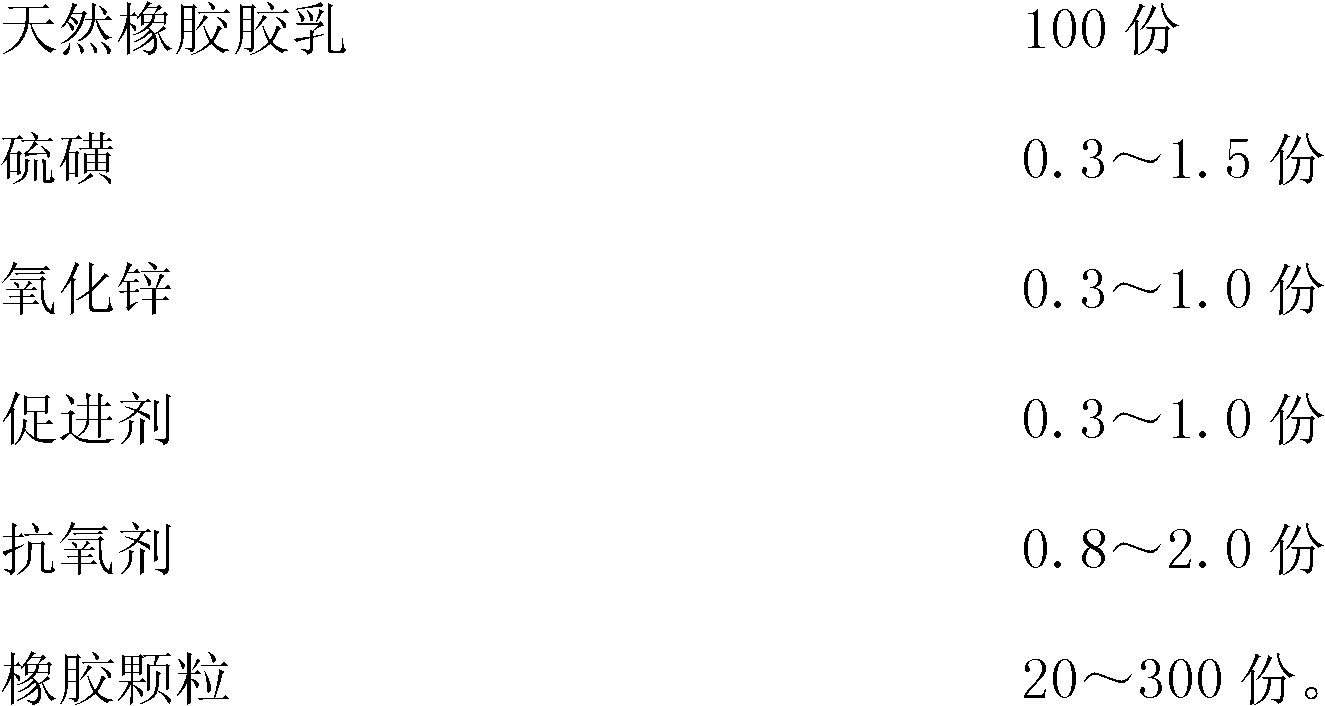

[0020] First prepare rubber latex, formula is natural rubber latex 100, sulfur 1.0, zinc oxide 0.7, accelerator ZDC 0.8, antioxidant 2641.5, stir with water or distilled water, form rubber latex, wherein, solid content reaches 30% in the rubber latex, namely It is the rubber latex used for the first dipping; according to this method, anti-skid rubber latex of the same composition is prepared, 100 parts of natural rubber latex, 1.0 part of sulfur, 0.7 part of zinc oxide, 0.8 part of accelerator ZDC, 1.5 parts of antioxidant 20 parts of rubber granules are stirred with water or distilled water to form non-slip rubber latex, so that the solid content in the non-slip rubber latex reaches 25%. Antioxidant is selected from antioxidant 264, and the diameter of rubber granules is 1.5mm. Soak the coagulant, the coagulant is 15% calcium nitrate solution, dry, park the rubber latex and non-slip rubber latex until all the air bubbles in the rubber latex and non-slip rubber latex disappear,...

Embodiment 2

[0022] First prepare rubber latex, 100 parts of natural rubber latex, 0.8 part of sulfur, 0.5 part of zinc oxide, 0.6 part of accelerator ZDC, 1.2 parts of antioxidant 264 are stirred with water or distilled water to form rubber latex, wherein, the solid content of rubber latex to 40%, which is the rubber latex used for the first dipping; according to this method, anti-skid rubber latex of the same composition is prepared, 100 parts of natural rubber latex, 0.8 part of sulfur, 0.5 part of zinc oxide, 0.6 part of accelerator ZDC, 1.2 parts of antioxidant, 200 parts of rubber particles are stirred with water or distilled water to form non-slip rubber latex, so that the solid content in the non-slip rubber latex is 35%, and the diameter of rubber particles is 4mm. Antioxidant is selected from antioxidant 264, and the mold (ceramic mould) impregnated coagulant, and coagulant is the calcium nitrate solution of 25% (weight percent concentration), oven dry, rubber latex and non-slip r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com