Hydrogen chloride removal device for purifying boron trichloride and boron trichloride purification system

A technology for purifying boron trichloride and hydrogen chloride, which is applied in the direction of boron halide compounds and boron halides, which can solve the problems of inaccurate refueling process, production delay, reaction suspension, etc., and achieve the effect of increasing continuity and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

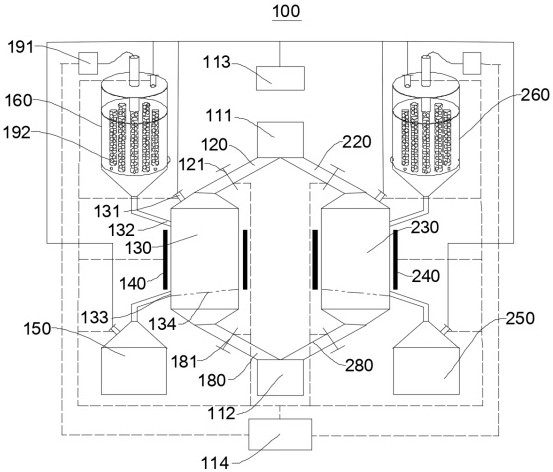

Please refer to figure 1, this embodiment provides a hydrogen chloride removal device 100 for purifying boron trichloride, which includes an upper pipe body 111, a first reaction unit and a second reaction unit arranged in parallel, a lower pipe body 112, a nitrogen device 113 and data Terminal 114. The upper pipe body 111 , the first reaction unit and the second reaction unit arranged in parallel, and the lower pipe body 112 are connected in sequence. The nitrogen plant 113 is connected to the first reaction unit and the second reaction unit. The data terminal 114 is connected to the upper pipe body 111 , the first reaction unit and the second reaction unit arranged in parallel, and the lower pipe body 112 .

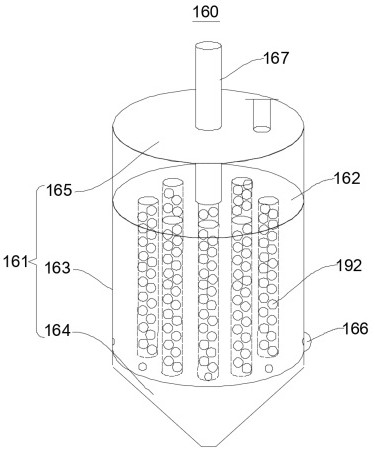

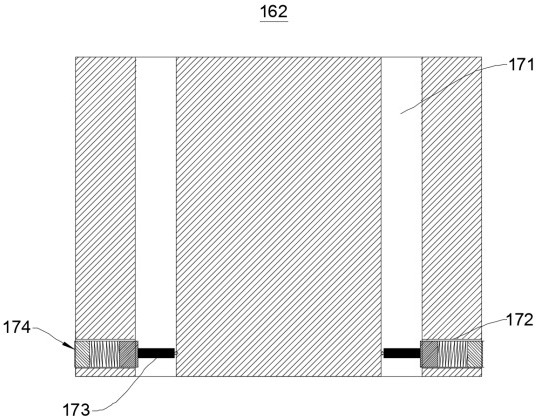

[0025] Please continue to refer to figure 1 , the first reaction unit includes a first inlet branch pipe 120 , a first reaction bed 130 , a first temperature control assembly 140 , a first waste residue storage tank 150 , a first feeding device 160 and a first gas out...

Embodiment 2

Please refer to Figure 5 , the present example provides a purification system 300 for boron trichloride, which includes a crude product supply device 310, a de-heavy rectification tower 320, a de-light rectification tower 330, and a dehydrochlorination device for purifying boron trichloride, which are sequentially connected. 100 , filter 340 , and condensing device 350 .

[0038] In summary, the present invention relates to a dehydrochlorination device for purifying boron trichloride and a purification system for boron trichloride. By connecting at least two reaction beds in parallel, the reaction beds work alternately, thereby realizing the continuous production of the entire process; , the feeding device and other components cooperate to realize the automatic replacement of the filler coated with alkaline earth metal boride, which further increases the continuity and automation of the entire process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com