Method for resource utilization of kitchen garbage anaerobic fermentation liquor

A technology of anaerobic fermentation liquid and kitchen waste, which is applied in the field of resource utilization of kitchen waste, can solve the problems of ineffective utilization of nutritional resources, large treatment pressure in sewage treatment plants, high treatment cost input, etc. Processing efficiency, reducing pretreatment energy consumption, and simplifying the effect of pretreatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, a method for resource utilization of anaerobic fermentation liquid of kitchen waste is provided.

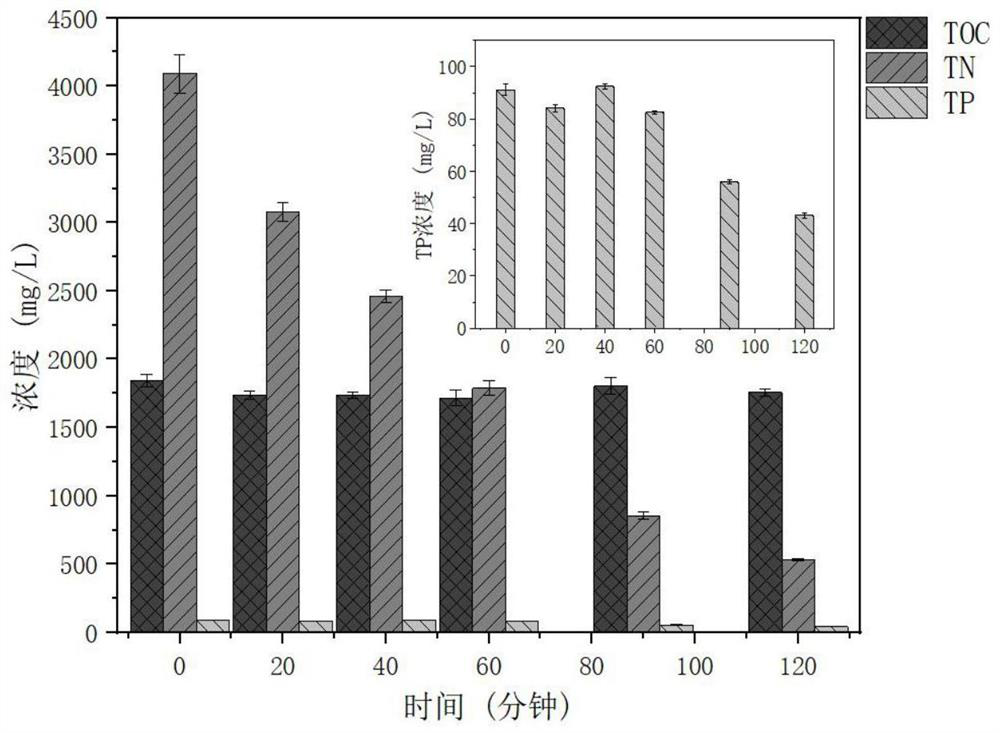

[0026] Using the scheme of this example, synchronously desalinate and remove nitrogen from the digester effluent from a food waste anaerobic digestion treatment plant in stable operation. The anaerobic fermentation liquid of kitchen waste in this example stays in the digester for 28 days. Solid (TS) content 3.05%, volatile matter (VS) 40.33% TS, suspended solids 9.8g / L, pH 7.9, conductivity 34.1mS / cm, total organic carbon (TOC) concentration 3294.7mg / L, total nitrogen ( TN) concentration 4920.7mg / L, of which ammonia nitrogen (AN) concentration 3395.2mg / L, total phosphorus (TP) concentration 99.3mg / L, Cl - Concentration 3536.6mg / L, Na + The concentration is 2305.0mg / L.

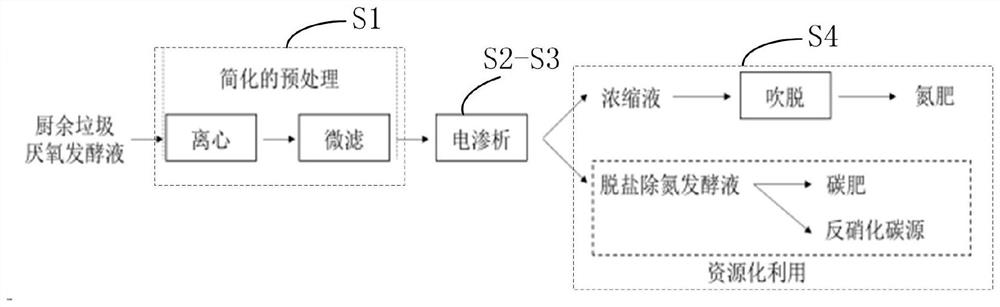

[0027] figure 1 It is a schematic flowchart of the method for resource utilization of kitchen waste anaerobic fermentation liquid in this embodiment.

[0028] Such as figure 1 As sh...

Embodiment 2

[0049] In this embodiment, a method for resource utilization of anaerobic fermentation liquid of kitchen waste is provided.

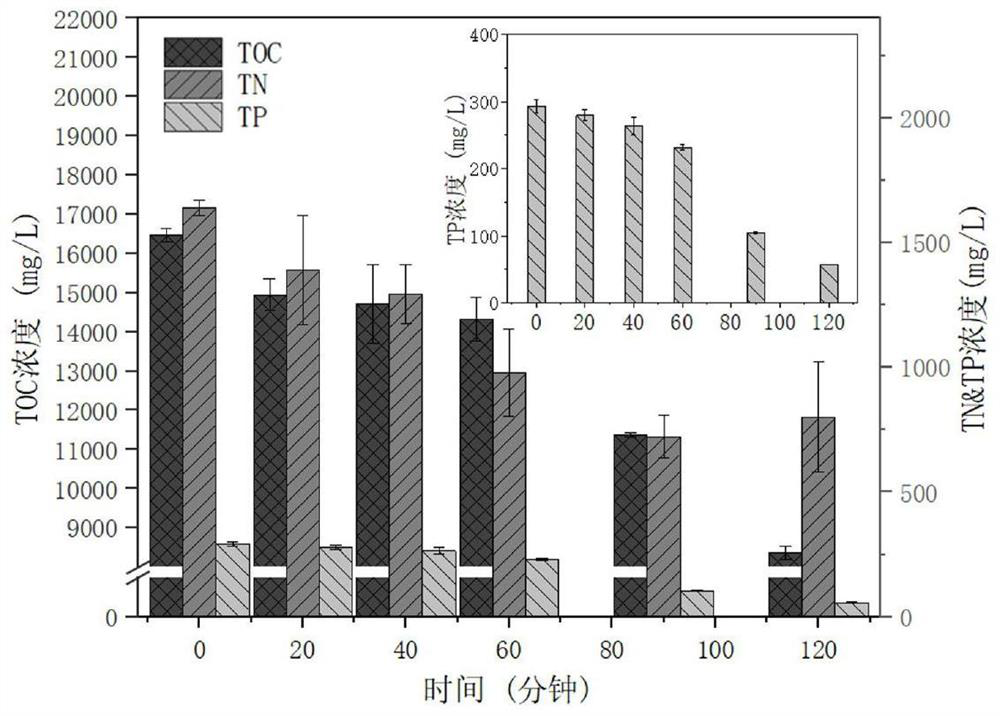

[0050] Using the scheme of this example, the fresh fermentation broth from a kitchen waste anaerobic digestion treatment plant was desalinated and denitrified synchronously. The residence time of the fresh fermentation broth was only 1-2 days, and it was rich in organic acids; Total solids content 5.83%, volatile matter 80.64% TS, suspended solids 18.3g / L, pH 4.19, conductivity 12.6mS / cm, total organic carbon concentration 22606mg / L, total volatile organic acids (VFAs) concentration 9941.7mg / L, total nitrogen concentration 1883.4mg / L, of which ammonia nitrogen concentration 1364.8mg / L, total phosphorus concentration 377.0mg / L, Cl - Concentration 2669.2mg / L, Na + The concentration is 1711mg / L.

[0051] In step S1, the anaerobic fermentation liquid of the kitchen waste to be treated removes large solid particles through a simplified pretreatment proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com