Prefabricated beam column assembly type system and construction method thereof

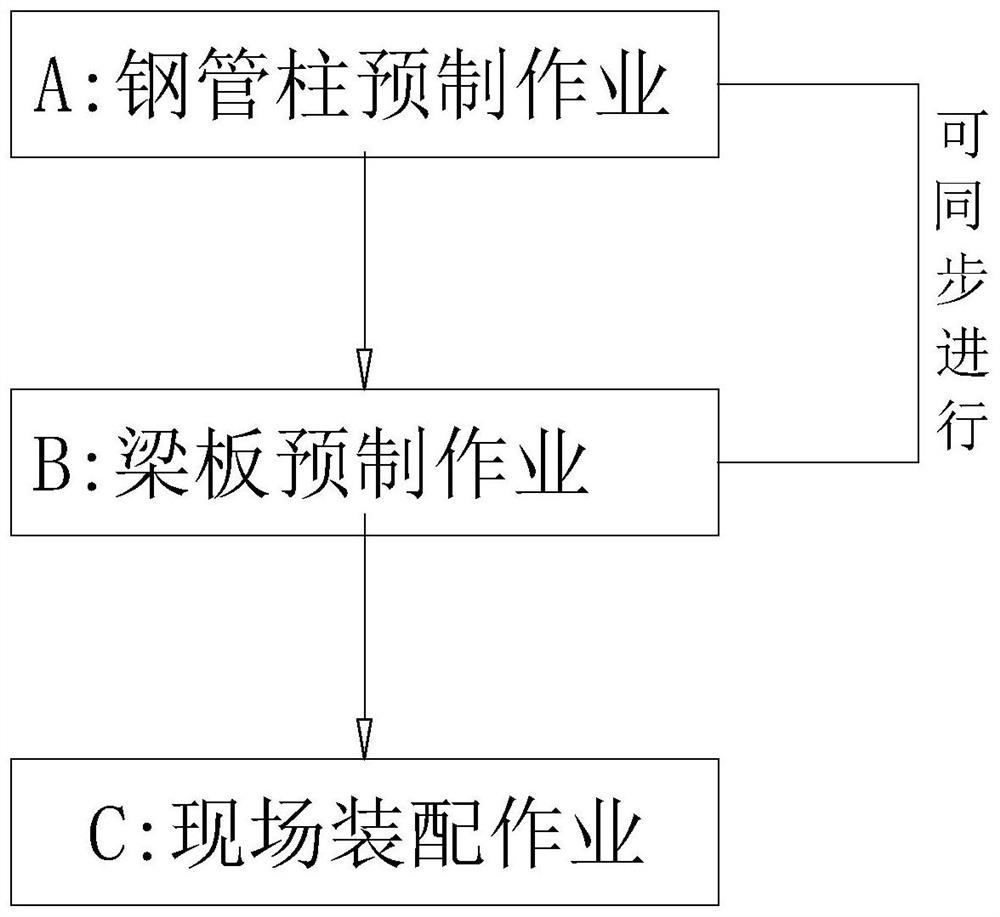

A prefabricated and systematic technology, applied in the field of construction, can solve the problems of high labor cost, long construction period, waste of water resources, etc., and achieve the effect of saving labor cost, saving welding process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

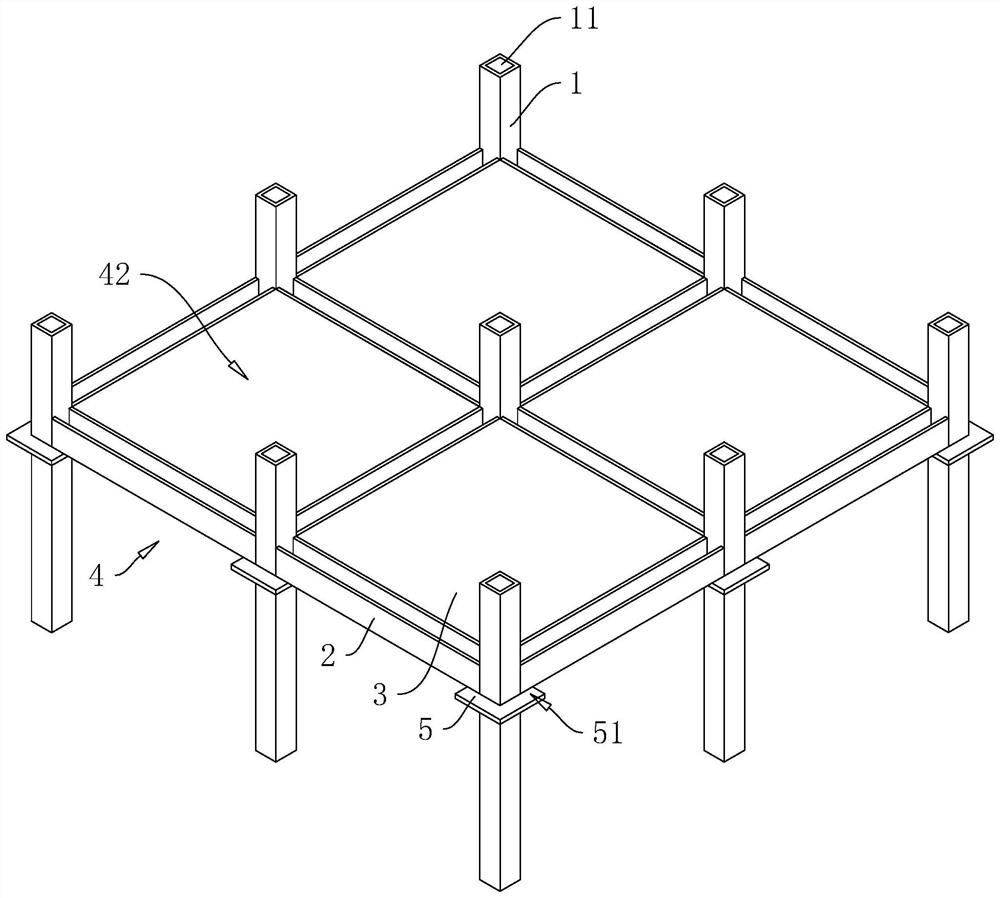

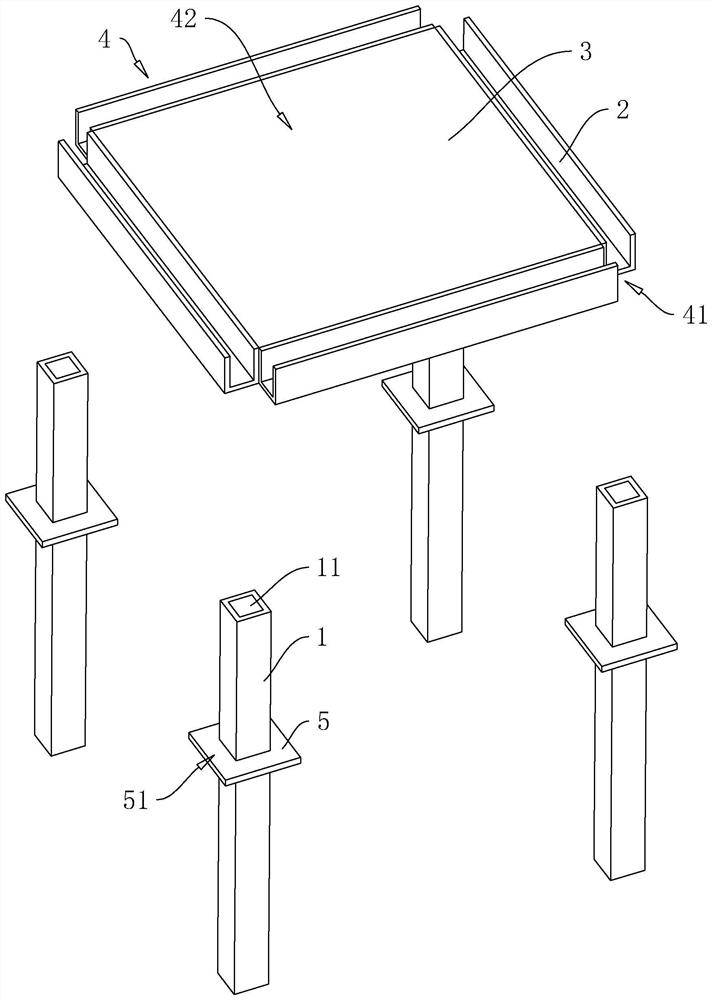

[0054] Attached to the following Figure 1-3 This application will be described in further detail.

[0055] The embodiment of the present application discloses a prefabricated beam-column assembly system.

[0056] refer to figure 1 and figure 2 , the prefabricated beam-column assembly system includes a plurality of prefabricated steel pipe columns 1, prefabricated steel beams 2 and prefabricated steel plates 3; the prefabricated steel pipe column 1 is formed with a pouring groove 11 for pouring concrete; in the later actual construction, pouring into the pouring groove 11 Concrete is used to delay the buckling of the prefabricated steel pipe and improve the compressive strength and fire resistance of the prefabricated steel pipe column 1 .

[0057] refer to figure 1 and figure 2 , the prefabricated steel beam 2 is provided with a plurality of and surrounding prefabricated steel plates 3 and forms a fixed connection with the top of the prefabricated steel beam 2 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com