Diluent, organosilicone pressure-sensitive adhesive and preparation method of organosilicone pressure-sensitive adhesive

A silicone pressure-sensitive adhesive and diluent technology, applied in the field of silicone rubber, can solve the problems of not reducing the use and emission of volatile organic compounds, not being able to meet the high-viscosity field, unfavorable coating use, etc., to improve long-term preservation And stability, improve heat resistance, reduce the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

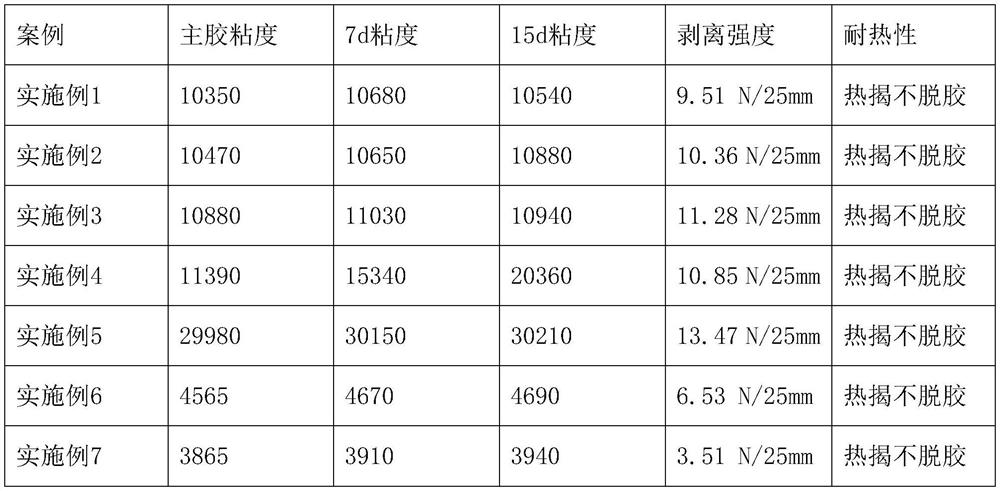

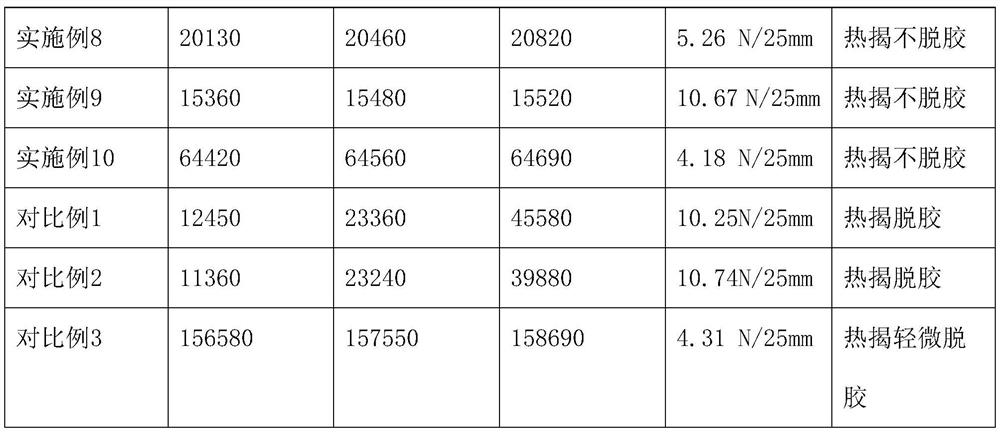

Examples

preparation example Construction

[0065] In another embodiment of the present invention, the preparation method of the diluent includes:

[0066] The linear hydroxyvinyl compound, the silane coupling agent and the first catalyst are mixed, heated and stirred, heated to 40-80°C for 1-3 hours, then heated to 80-100°C and reacted for 1-3 hours; -100°C for 0.5-2.5h and cooling.

[0067] The silicone pressure-sensitive adhesive prepared by the patent is green and environmentally friendly, has no polluting solvent, has a simple preparation process, and is easy to realize industrialization.

Embodiment 1

[0070] Preparation of diluent: 50 parts of 8-nonen-1-ol, 50 parts of methyltrimethoxysilane and 1 part of n-butyl titanate were placed in a 1L four-necked flask equipped with vigorous stirring, thermometer and reflux tube , heated to 40°C for 2h; then heated to 80°C for 1h, then kept at 90°C for 1h in a vacuum environment, stopped heating, and cooled to room temperature.

[0071] Preparation of silicone pressure sensitive adhesive master glue: add 100 parts of MQ silicone resin ((CH) with 70% solid content in a 500 mL open reactor 3 SiO 1 / 2 ) 0.75 (SiO 4 / 2 ), M w 6000), 50 parts of polydimethylsiloxane with a viscosity of 1000 mPa·s and an alkenyl end group, stir evenly, heat up to 120 ° C, reduce the pressure to -0.1 MPa for 3 hours, and remove the solvent to prepare After the mixture is obtained, 5 parts of the above diluent are added, and then 4 parts of a crosslinking agent (linear polymethyl hydrogen siloxane) with a hydrogen content of 0.8% and a viscosity of 30 mPa·...

Embodiment 2

[0074] Preparation of diluent: 50 parts of 6-hepten-1-ol, 35 parts of methyltrimethoxysilane, 15 parts of methacryloyloxypropion were added to a 1L four-necked flask equipped with vigorous stirring, thermometer and reflux tube Triethoxysilane and 0.5 part of isobutyl titanate were heated to 40 °C for 2 h; then heated to 80 °C for 1 h, then kept at 90 °C for 1 h in a vacuum environment, stopped heating, and cooled to room temperature.

[0075] The preparation methods and parameters of the silicone pressure-sensitive adhesive and the main adhesive are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com