High-strength wear-resistant rubber and preparation method thereof

A wear-resistant rubber and high-strength technology, applied in the rubber field, can solve the problems of poor wear resistance and low strength, achieve excellent wear resistance, improve aging resistance, and improve rubber strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

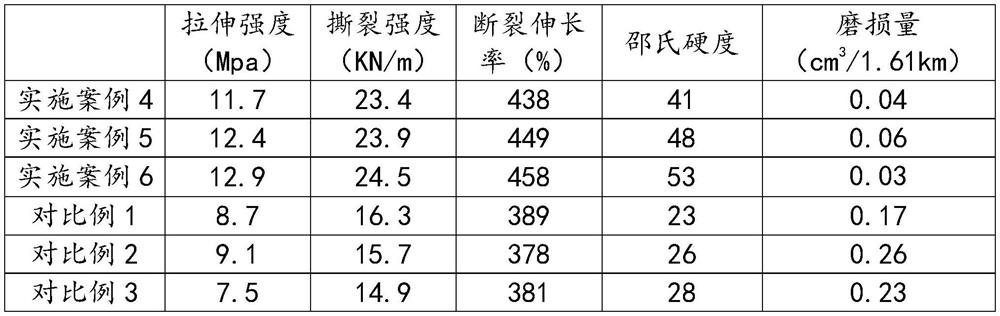

Examples

Embodiment 1

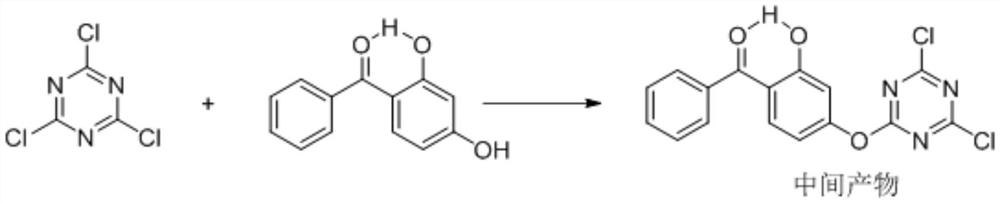

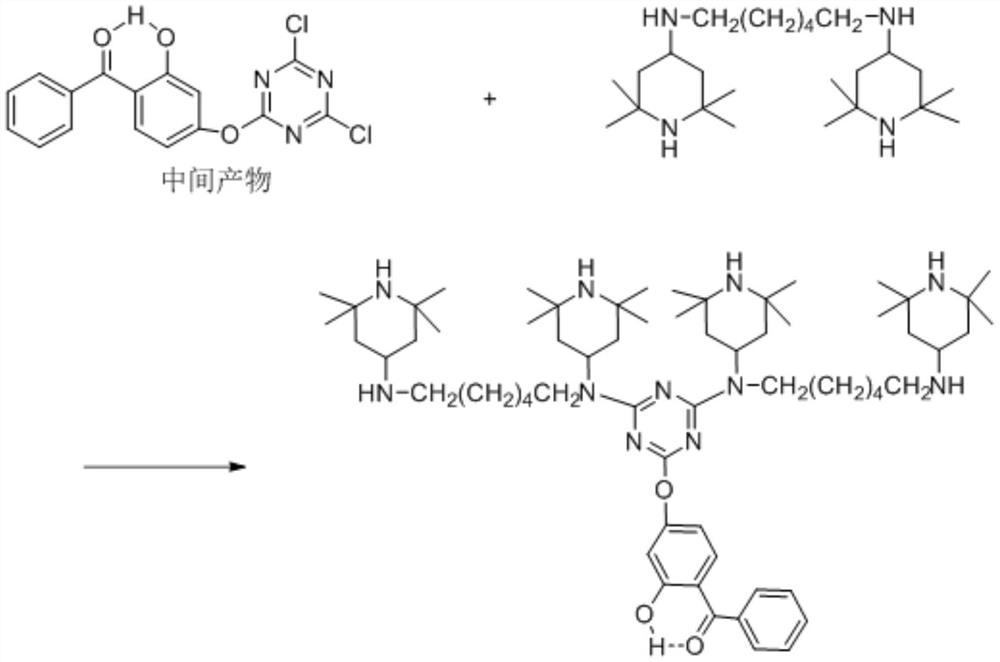

[0034] Composite light stabilizers are made by the following steps:

[0035]Step S1: Add cyanogen trimer to a three-mouth flask containing a stirrer and a thermometer, then add acetone to dissolve it, then place the three flasks in an ice bath, continue stirring for 15 min, and then slowly add an acetone solution containing 2,4-dihydroxybenzophenone to the three-mouth flask, and maintain the pH of the system at 6, the temperature is 0 ° C, the drip is completed within 60 min, the temperature remains constant, and the pH of the system is adjusted by 10% sodium hydroxide solution, so that the pH of the system is between 6, After the pH value is stabilized, continue to stir for 2h to obtain the reaction solution, cool the reaction liquid to room temperature, and then pour into acetone, and then carry out decompression extraction, wash with acetone twice, and then dry in a vacuum drying box to obtain the intermediate product, wherein, cyanide trichloride, 2,4-dihydroxybenzophenone, ac...

Embodiment 2

[0038] Composite light stabilizers are made by the following steps:

[0039] Step S1: Add cyanogen trimer to a three-mouth flask containing a stirrer and a thermometer, then add acetone to dissolve it, then place the three flasks in an ice bath, continue stirring for 15 min, and then slowly add an acetone solution containing 2,4-dihydroxybenzophenone to the three-mouth flask, and maintain the pH of the system at 6, the temperature is 0 ° C, the drip is completed within 60 min, the temperature remains constant, and the pH of the system is adjusted by 10% sodium hydroxide solution, so that the pH of the system is between 6, After the pH value is stabilized, continue to stir for 2h to obtain the reaction solution, the reaction liquid is cooled to room temperature, and then poured into acetone, and then decompression filtration, washed with acetone twice, and then dried in a vacuum drying box to obtain the intermediate product, wherein the amount of cyanide tricoride, 2,4-dihydroxyben...

Embodiment 3

[0042] Composite light stabilizers are made by the following steps:

[0043] Step S1: Add cyanogen trimer to a three-mouth flask containing a stirrer and a thermometer, then add acetone to dissolve it, then place the three flasks in an ice bath, continue stirring for 15 min, and then slowly add an acetone solution containing 2,4-dihydroxybenzophenone to the three-mouth flask, and maintain the pH of the system at 6, the temperature is 0 ° C, the drip is completed within 60 min, the temperature remains constant, and the pH of the system is adjusted by 10% sodium hydroxide solution, so that the pH of the system is between 6, After the pH value is stabilized, continue to stir for 2h to obtain the reaction solution, the reaction liquid is cooled to room temperature, and then poured into acetone, and then decompression filtration, washed with acetone twice, and then dried in a vacuum drying box to obtain the intermediate product, wherein the amount of cyanide trimethyl chloride, 2,4-dih...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com