Cutting-resistant rubber track for engineering machinery and preparation method of cutting-resistant rubber track

A technology for rubber crawlers and construction machinery, which is applied in the field of cut-resistant rubber crawlers for construction machinery and its preparation, and can solve problems such as ground wear, short driving life, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

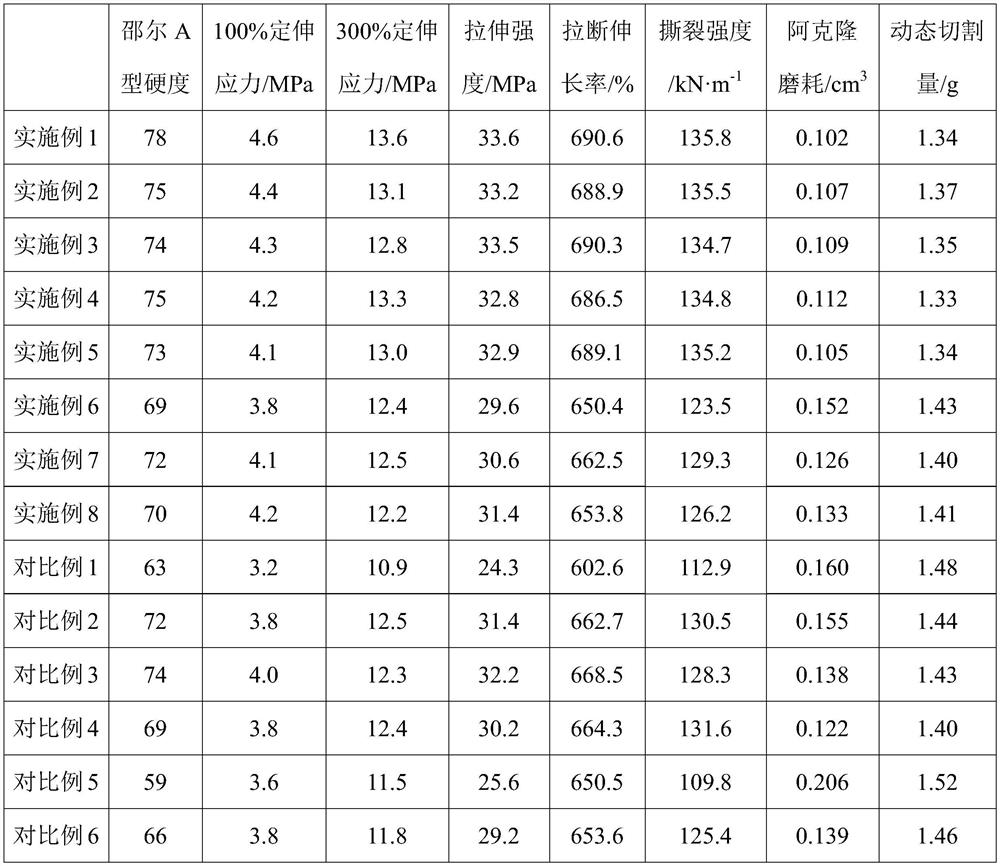

Examples

Embodiment 1

[0025] A cut-resistant rubber crawler track for construction machinery, comprising rubber material, core gold, and cord, and the rubber material includes the following components:

[0026] 80 parts of natural rubber, 20 parts of cis-butadiene rubber, 15 parts of epoxidized solution-polymerized styrene-butadiene rubber, 5 parts of coumarone resin, 4 parts of styrene resin, 50 parts of carbon black, 10 parts of white carbon black, core-shell structure filler 20 parts, 10 parts of phthalated modified nanocrystalline cellulose whiskers, 1 part of stearic acid, 0.1 part of cerium sorbate, 5 parts of sulfur, 0.25 part of accelerator DM, and 0.25 part of accelerator OTOS.

[0027] Wherein, the preparation method of epoxidized solution-polymerized styrene-butadiene rubber is as follows:

[0028] After dissolving 100g polystyrene-butadiene rubber in 1L n-hexane, then adding 0.2g Tween 80 and 6g formic acid, stirring for 20min, then adding 15mL hydrogen peroxide dropwise, stirring the r...

Embodiment 2

[0036] A cut-resistant rubber crawler track for construction machinery, comprising rubber material, core gold, and cord, and the rubber material includes the following components:

[0037] 100 parts of natural rubber, 40 parts of cis-butadiene rubber, 20 parts of epoxidized solution-polymerized styrene-butadiene rubber, 6 parts of coumarone resin, 4 parts of styrene resin, 60 parts of carbon black, 10 parts of white carbon black, core-shell structure filler 20 parts, 10 parts of phthalate-modified nanocrystalline cellulose whiskers, 2 parts of stearic acid, 0.2 part of cerium sorbate, 5 parts of sulfur, 0.25 part of accelerator DM, and 0.25 part of accelerator OTOS.

[0038] Wherein, the preparation method of epoxidized solution-polymerized styrene-butadiene rubber is as follows:

[0039] After dissolving 100g polystyrene-butadiene rubber in 1L n-hexane, then adding 0.2g Tween 80 and 6g formic acid, stirring for 40min, then adding 15mL hydrogen peroxide dropwise, stirring for ...

Embodiment 3

[0047] A cut-resistant rubber crawler track for construction machinery, comprising rubber material, core gold, and cord, and the rubber material includes the following components:

[0048] 60 parts of natural rubber, 20 parts of cis-butadiene rubber, 10 parts of epoxidized solution-polymerized styrene-butadiene rubber, 4 parts of coumarone resin, 2 parts of styrene resin, 40 parts of carbon black, 5 parts of white carbon black, core-shell structure filler 10 parts, 5 parts of phthalated modified nanocrystalline cellulose whiskers, 1 part of stearic acid, 0.1 part of cerium sorbate, 3 parts of sulfur, 0.25 part of accelerator DM, and 0.25 part of accelerator OTOS.

[0049] Wherein, the preparation method of epoxidized solution-polymerized styrene-butadiene rubber is as follows:

[0050] After dissolving 100g polystyrene-butadiene rubber in 1L n-hexane, then adding 0.2g Tween 80 and 6g formic acid, stirring for 10min, then adding 15mL hydrogen peroxide dropwise, stirring the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com