Polymer, photoresist, photoresist layer and photoetching process

A technology of photoresist layer and polymer, which is applied in the field of photoresist layer and photolithography process, photoresist, and polymer, and can solve the problems of photoresist heat resistance, adverse effects on device performance, and rise in substrate temperature and other problems, to achieve the effect of good imaging, high production efficiency, and balanced solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

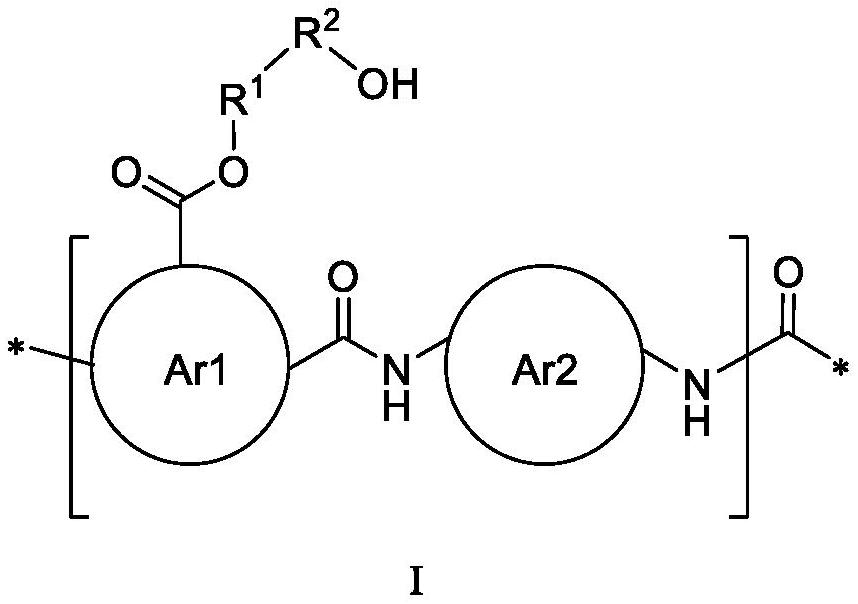

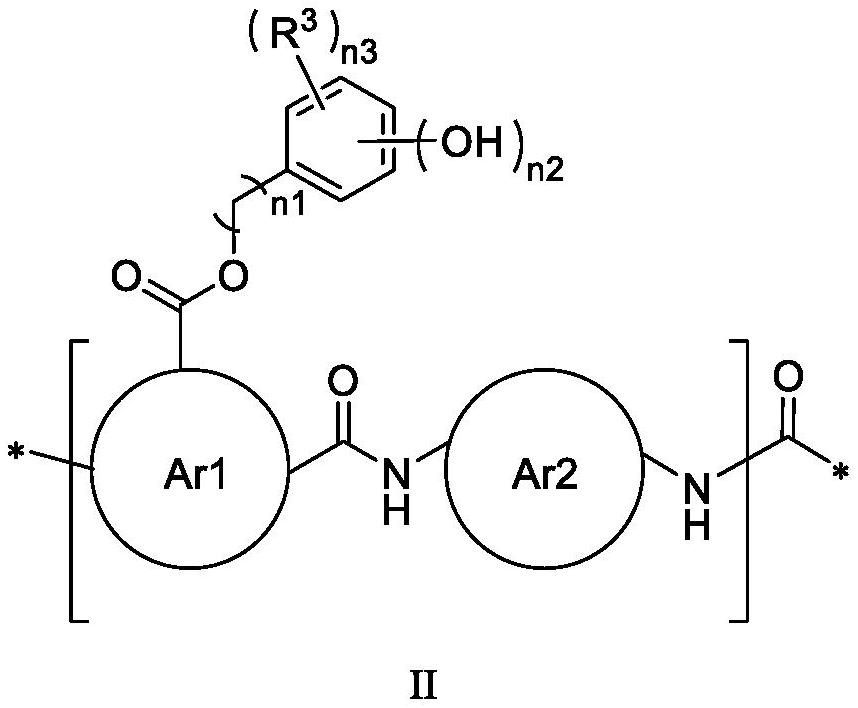

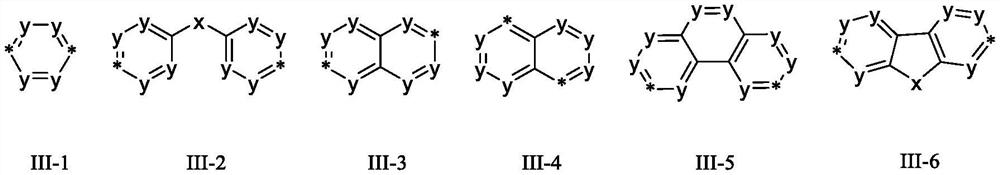

[0104] The present invention also provides a preparation method of the aforementioned polymer, comprising the following steps:

[0105] Will with esterification agent carry out the esterification reaction, and then combine the product of the esterification reaction with A condensation reaction is carried out to prepare the polymer.

[0106] In some embodiments, in order to improve the condensation reaction activity, the product of the aforementioned esterification reaction can be subjected to acylation treatment, and the acylation treatment can use any acylation reagent known in the art, and a typical example can be thionyl chloride.

[0107] In some embodiments, the condensation reaction may be catalytic condensation or high temperature dehydration condensation.

[0108] Preferably, the Dissolved in a solvent, the product of the aforementioned esterification reaction was then slowly added dropwise to the solution. The solvent can be selected from N-methylpyrrolidone....

Embodiment 1

[0159] (1) under ice-water mixed bath condition, add 100mL NMP (N-methylpyrrolidone) solvent, 21.8g (100mmol) pyromellitic dianhydride to the reactor, then add 4-hydroxybenzyl alcohol 14.9g ( 120mmol), after stirring at room temperature for 2 hours, the reaction kettle was placed in the methanol refrigerant refrigeration tank of -20 ° C, and then slowly dripped 50 mL of thionyl chloride into the reaction kettle until all solids were completely dissolved, and taken out from the refrigerant. The reaction kettle was stirred at room temperature for 3 hours, and the excess thionyl chloride was distilled off under reduced pressure at 50 ° C to obtain 31.9 g of the chlorinated product;

[0160] (2) add 100mL NMP in the above-mentioned reactor that the product after chlorination is housed, stir until the solid is completely dissolved, put into an ice-water bath, while stirring will be dissolved in the 3,3'-dihydroxyl linkage in the NMP of 20ml Aniline (HAB) 21.6g (100mmol) was slowly ...

Embodiment 2

[0163] Basically the same as Example 1, the difference is that in step (1), the 4,4'-oxydiphthalic anhydride of an equivalent amount is used instead of pyromellitic dianhydride, and the polymer obtained in step (2) is The weight average molecular weight was 38500 Da.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com