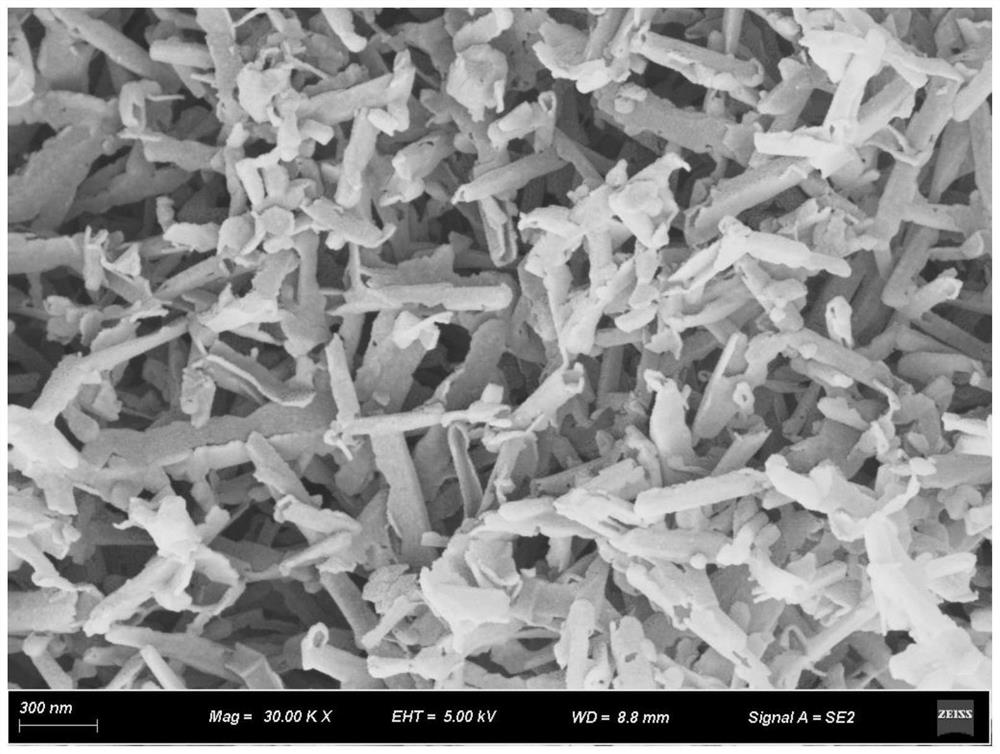

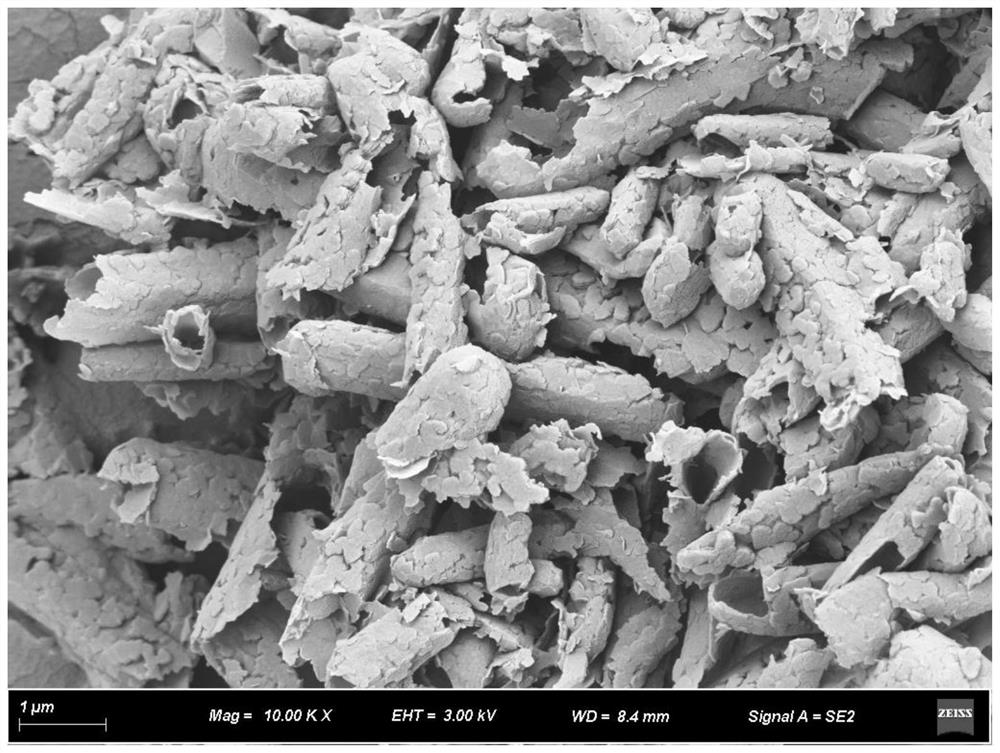

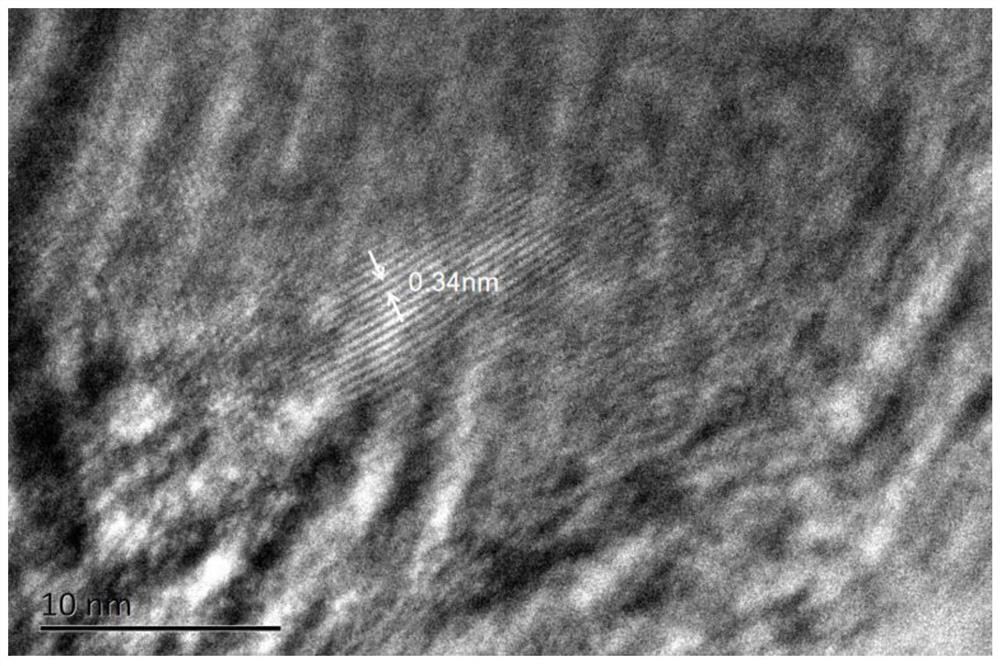

Boron nitride hollow tube with tube wall formed by directional coverage of lamellas and preparation method of boron nitride hollow tube

A boron nitride, hollow tube technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of unsuitable mass production, low output, small surface area, etc., achieve good application prospects, and improve specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a boron nitride hollow tube with lamella directionally covering and forming a tube wall, comprising the following steps:

[0041] (1) Under magnetic stirring at room temperature, the H 3 BO 3 and Mg(NO 3 ) 2 Mix and dissolve in deionized water so that the concentrations are 3 mol / L and 2 mol / L respectively, and then dropwise add ammonia water with a concentration of 25% to pH 10 to obtain a precursor solution. After that, take 80ml of the precursor solution and put it into a 100ml polytetrafluoroethylene-lined hydrothermal reactor, heat it to 200°C, keep it under isothermal conditions for 20h, then naturally cool to room temperature, filter the product, use Washed with ionized water three times, and vacuum-dried at 110 °C for 12 h to obtain a boron-containing precursor;

[0042] (2) Take the boron-containing precursor prepared above, put it into a tubular furnace, and pass into ammonia gas after vacuuming, and the ammonia gas flow rate is 100m...

Embodiment 2

[0050] A method for preparing a boron nitride hollow tube with lamella directionally covering and forming a tube wall, comprising the following steps:

[0051] (1) Under magnetic stirring at room temperature, the H 3 BO 3 and Mg(NO 3 ) 2 Mix and dissolve in deionized water so that the concentrations are 3 mol / L and 2 mol / L respectively, and then dropwise add ammonia water with a concentration of 25% to pH 10 to obtain a precursor solution. After that, take 80ml of the precursor solution and put it into a 100ml polytetrafluoroethylene-lined hydrothermal reactor, heat it to 200°C, keep it under isothermal conditions for 20h, then naturally cool to room temperature, filter the product, use Washed with ionized water three times, and vacuum-dried at 110 °C for 12 h to obtain a boron-containing precursor;

[0052] (2) Take the boron-containing precursor prepared above, put it into a tube furnace, and pass into ammonia gas after vacuuming, and the ammonia gas flow rate is 150ml / m...

Embodiment 3

[0055] A method for preparing a boron nitride hollow tube with lamella directionally covering and forming a tube wall, comprising the following steps:

[0056] (1) Under magnetic stirring at room temperature, the H 3 BO 3 and Mg(NO 3 ) 2 Mix and dissolve in deionized water so that the concentrations are 3 mol / L and 2 mol / L respectively, and then dropwise add ammonia water with a concentration of 25% to pH 10 to obtain a precursor solution. After that, take 80ml of the precursor solution and put it into a 100ml polytetrafluoroethylene-lined hydrothermal reactor, heat it to 200°C, keep it under isothermal conditions for 20h, then naturally cool to room temperature, filter the product, use Washed with ionized water three times, and vacuum-dried at 110 °C for 12 h to obtain a boron-containing precursor;

[0057] (2) Take the boron-containing precursor prepared above, put it in a tube furnace, and pass ammonia gas after vacuuming. The flow rate of ammonia gas is 200ml / min, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com