Asymmetric-structure polyether-ether-ketone hollow fiber membrane

An asymmetric structure, polyether ether ketone technology, applied in the direction of membrane, membrane technology, non-woven fabrics, etc., can solve the problems of poor pressure resistance, poor membrane porosity and permeability, low strength of PEEK hollow fiber membrane, etc., to achieve Low environmental pollution, controllable membrane structure, and guaranteed membrane permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

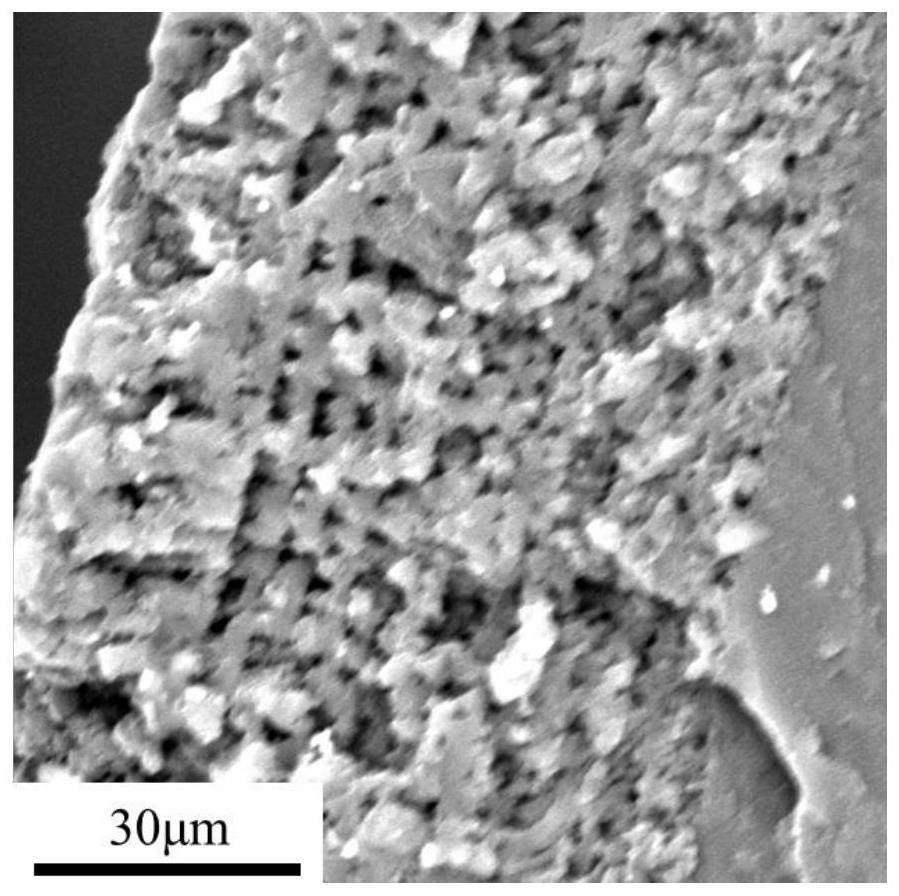

[0026] The present invention provides an asymmetrical structure PEEK hollow fiber membrane and a method for preparing it, wherein the method comprises the following steps:

[0027]Step 1: Mix the pre-dried complete PEEK resin, blended polymer and plasticizer and extruded and granulated by extruder to obtain a uniform spinning granule;

[0028] The blended polymer is polyetherimide, polyethylene oxide, polyimide, polyarylene sulfone, polyethersulfone, polyphenylene sulfone and at least one of polyaryl esters;

[0029] The plasticizer is a high boiling point solvent, is diphenyl sulfone, diphenyl isophthalate, diphenyl terephthalate and benzophenone at least one;

[0030] The ratio is PEEK resin 30 ~ 60 wt%, blended polymer 30 ~ 60 wt, plasticizer 10 ~ 40 wt, the sum of each component is 100%;

[0031] Step 2, set the screw spinning machine feeding speed, host speed, metering pump speed, high temperature channel length and temperature, air cooling length, the first and second channe...

Embodiment 1

[0037] (1) Pre-dried complete 45 wt% PEEK resin, 45 wt% polyetherimide, 10 wt% diphenyl sulfone by high-speed mixer fully mixed and then extruded at 340 °C to obtain spinning granules;

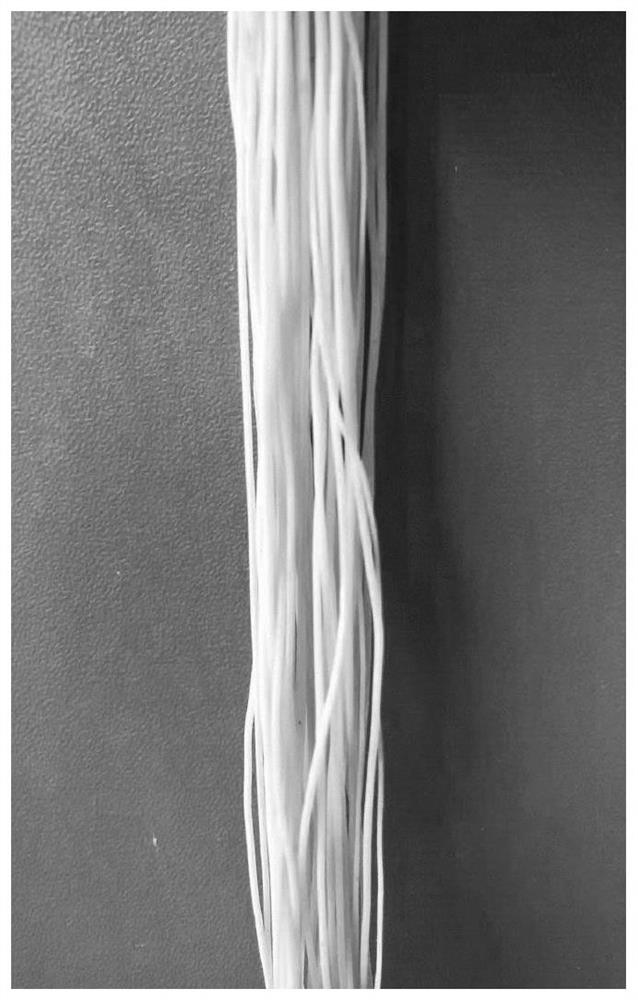

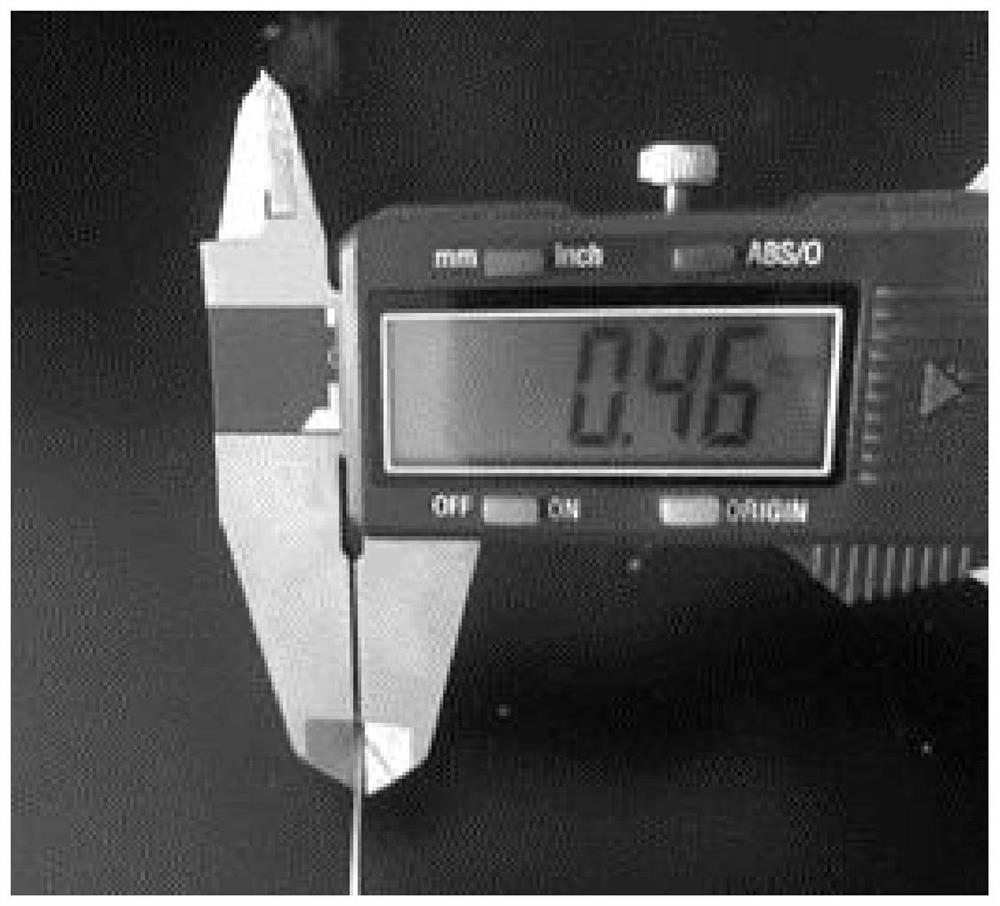

[0038] (2) Set the screw spinning machine feeding speed 15 r / min, the main machine speed 8 r / min, the metering pump speed 18 r / min, the high temperature channel length 40 cm, the temperature 280 °C, the air cooling temperature 15 °C, the length 50 cm, the roller rate (diameter 15 cm) 8r / min, the first tensile rate 15 r / min, the second stretch rate 25 r / min, infrared heating temperature 200 °C, winding (diameter 55 cm) rate 20r / min, The particles are melted at 340 °C by the screw extruder through the automatic feeder, quantitatively extruded by the hollow spinneret assembly, the nitrogen temperature is 25 °C inside the component, and the spinning melt is successively passed through the high temperature Yongdao, air-cooled Yongdao, stretching, shaping winding, dichloromethane and ethanolamine extrac...

Embodiment 2

[0044] (1) Pre-dried 44 wt% PEEK resin, 46 wt% polyimide, 10 wt% diphenyl isophthalate by high-speed mixing machine fully mixed and then extruded at 340 °C to obtain spinning pellets;

[0045] (2) Set the screw spinning machine feeding speed 15 r / min, the main machine speed 10 r / min, the metering pump speed 20 r / min, the high temperature channel length 50 cm, the temperature 300 °C, the air cooling 25 °C, the length 40 cm, the rotary roller rate (diameter 15 cm) 8 r / min, the first stretch rate 15 r / min, the second stretch rate 25 r / min, infrared heating temperature 200 °C, winding (diameter 55 cm) rate 20 r / min, The particles are melted at 340 °C by the screw extruder through the automatic feeder, quantitatively extruded by the hollow spinneret assembly, the nitrogen temperature is 25 °C inside the component, and the spinning melt is successively passed through the high temperature yongdao, air-cooled Yongdao, stretching, stereotyping winding, N-methylpyrrolidone extraction, clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com