Manufacture method for composite-material launch canister of high-altitude fire-extinguishing rocket

A technology of composite materials and manufacturing methods, which is applied in the field of manufacturing multifunctional composite material launching tubes, can solve the problems of mass casualties, personnel evacuation, and fire fighting difficulties, etc., achieve high temperature resistance and erosion resistance, and overcome connection strength Not enough, the effect of strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

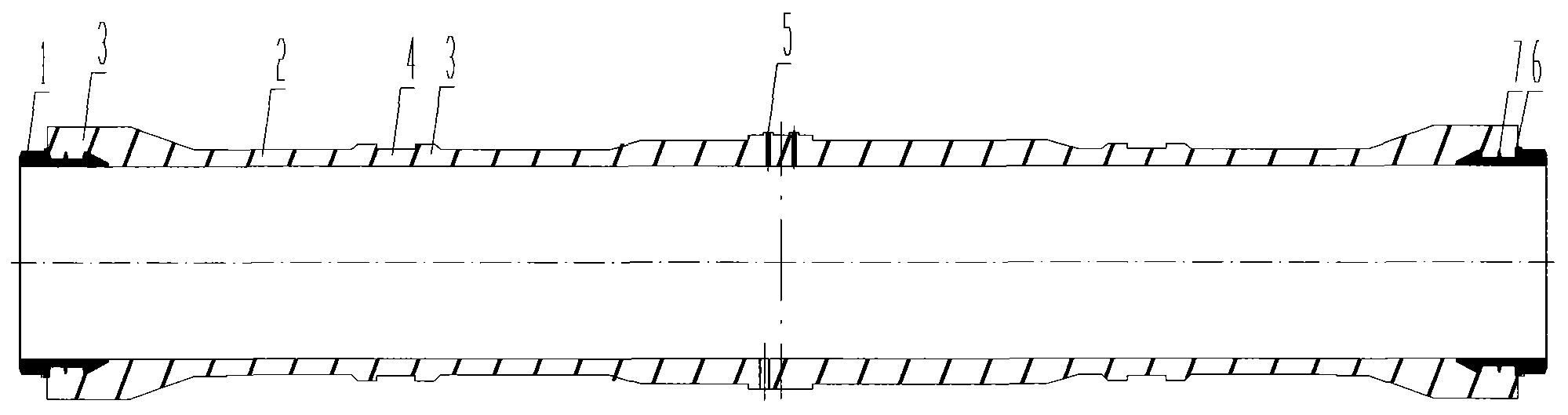

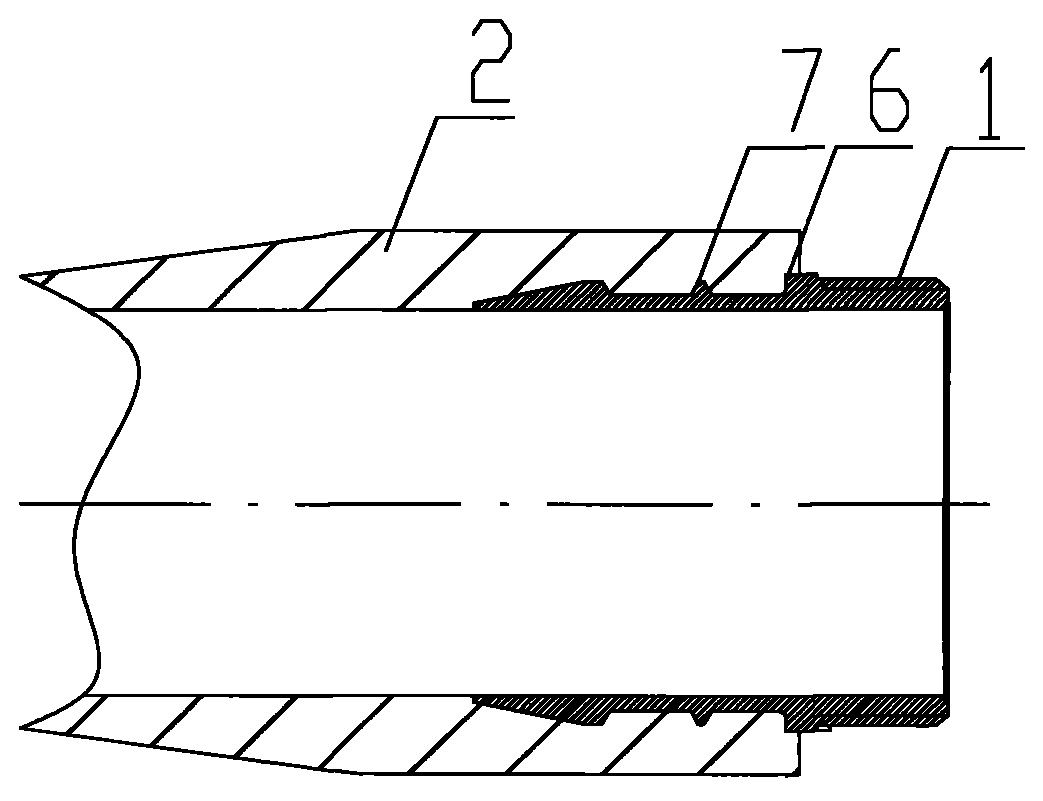

[0033] Such as Figure 1-2 As shown, a high-altitude fire extinguishing rocket composite material launching tube prepared by the manufacturing method of the present invention includes two metal liners 1 and a composite material cylinder 2 . The metal liner 1 has an annular step 6 and at least one annular protrusion 7 in sequence, and the annular step 6 has rounded corners. The two ends of the composite material cylinder 2 are respectively sealed and connected to a metal liner 1, the annular step 6 and the annular protrusion 7 of the metal liner 1 are installed in the composite material cylinder 2, and the metal liner 1 An annular step 6 is located at the end of the composite barrel 2 .

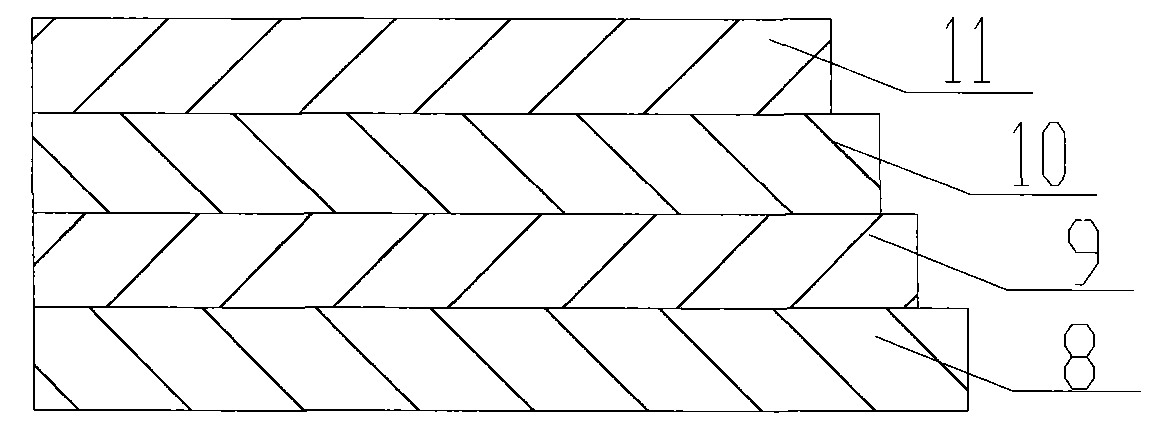

[0034] Such as image 3 As shown, the composite material barrel 2 includes a heat-resistant anti-scour coating 8 in the inner layer, a sealing layer 9 in the middle layer and a bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com