High-strength bamboo-plastic composite material for container bottom plate

A container bottom plate and composite material technology, which is applied in the field of high-strength bamboo-plastic composite materials for container bottom plates and its preparation, can solve the problems of high-strength container bottom plates, strength, impact resistance, poor toughness, interface wettability and Poor adhesion and other problems, to achieve the effect of improving waste utilization, improving mechanical strength, and reducing surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

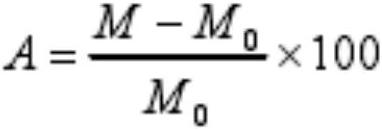

Method used

Image

Examples

Embodiment 1

[0032]In this embodiment, the high-strength bamboo-plastic composite material used for the bottom plate of the container comprises the following specific steps: mixing 31.3 parts of HDPE, 8.7 parts of LLDPE, 3.4 parts of recycled PE resin, 6.6 parts of recycled PC resin and 5 parts of polyvinyl butyral, Stir for 5 minutes, then add 50 parts of modified bamboo powder and 2 parts of coupling agent, stir for 10 minutes, and dry at 100°C for 2 hours to obtain a preliminary mixture; Calcium acid, 0.2 parts of zinc stearate, 1.5 parts of anti-aging agent 264 were sequentially added to a high-speed mixer and mixed for 20 minutes at a mixing temperature of 120 ° C, and then directly passed into a twin-screw extruder for extrusion and granulation. The exit temperature is 150-185°C, and the screw speed is 45r / min to obtain high-strength bamboo-plastic composite materials.

[0033] The preparation method of above-mentioned modified bamboo powder is: join 1 part of sodium alginate in the ...

Embodiment 2

[0037] In this embodiment, the high-strength bamboo-plastic composite material used for the bottom plate of the container comprises the following specific steps: mixing 18 parts of HDPE, 7 parts of LLDPE, 1.25 parts of recycled PE resin, 3.75 parts of recycled PC resin and 8 parts of polyvinyl butyral, Stir for 5 minutes, then add 70 parts of modified bamboo powder and 4 parts of coupling agent, stir for 5 minutes, and dry at 100°C for 2 hours to obtain a preliminary mixture; Calcium acid calcium, 1 part of polyethylene wax, and 0.5 part of carbon black were sequentially added to a high-speed mixer and mixed for 10 minutes at a mixing temperature of 130 ° C, and then directly passed into a twin-screw extruder for extrusion and granulation. Among them, the extruder The temperature is 150-185° C., the screw speed is 45 r / min, and the high-strength bamboo-plastic composite material is obtained.

[0038] The preparation method of above-mentioned modified bamboo powder is: join 3 p...

Embodiment 3

[0042] In this embodiment, the high-strength bamboo-plastic composite material used for the bottom plate of the container comprises the following specific steps: mixing 22.5 parts of HDPE, 7.5 parts of LLDPE, 2.5 parts of recycled PE resin, 7.5 parts of recycled PC resin and 6 parts of polyvinyl butyral, Stir for 5 minutes, then add 60 parts of modified bamboo powder and 3 parts of coupling agent, stir for 10 minutes, and dry at 100°C for 2 hours to obtain a preliminary mixture; calcium carbonate, 1 part of ethylene bisstearamide, and 1 part of anti-aging agent were sequentially added to a high-speed mixer and mixed for 20 minutes at a mixing temperature of 130 ° C, and then directly passed into a twin-screw extruder for extrusion and granulation, wherein , the temperature of the extruder is 150-185° C., and the screw speed is 45 r / min to obtain a high-strength bamboo-plastic composite material.

[0043] The preparation method of above-mentioned modified bamboo powder is: join...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com