Nickel-based alloy/aluminum alloy or aluminum dissimilar material laser welding method

A technology of nickel-based alloys and dissimilar materials, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of weld brittle fracture, penetrating cracks, uneven distribution of brittle intermetallic compounds, etc. Effect of chemical composition, relieving internal stress, improving weld forming quality and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

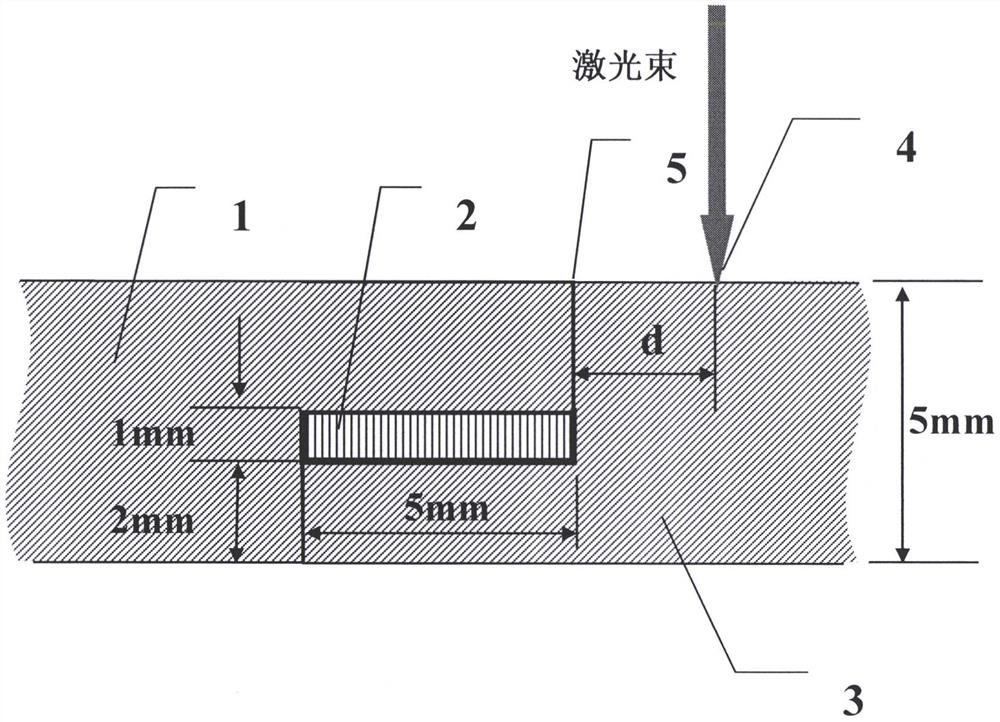

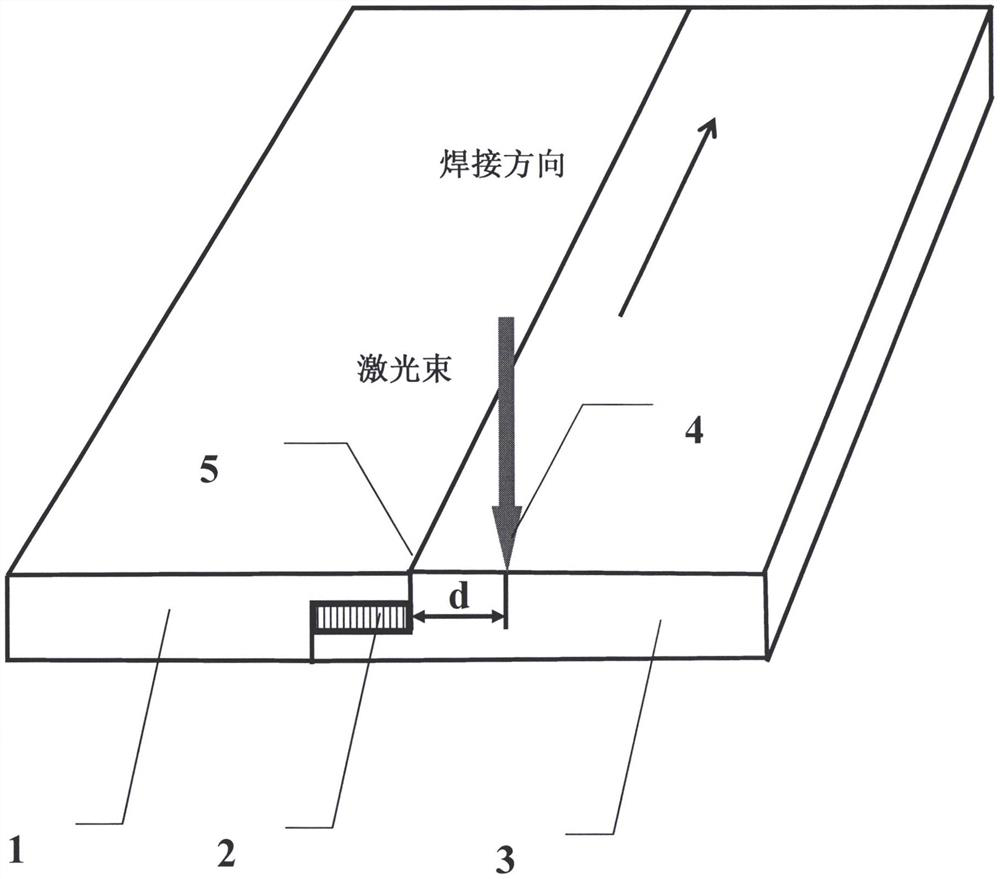

[0025] Such as figure 1 As shown, firstly, the surface of nickel-based alloy plates 1 and 3 and aluminum alloy plate 2 is treated before welding to remove pollutants, and the surface roughness is 4-6um. The nickel-based alloy plates 1 and 3 have the same material and size, and the nickel-based alloy plates 1 and 3 and the aluminum alloy plate 2 have the same length. The aluminum alloy thin plate 2 is horizontally placed on the step layer of the nickel-based alloy plate 3, the step layer of the nickel-based alloy plate 1 is placed on the aluminum alloy thin plate 2, and the two nickel-based alloy plates 1 and 3 are butted. The assembly fixture is used to fix, closely contact, reduce the assembly gap, and form a two-metal three-layer composite structure of nickel-based alloy plate 1-aluminum alloy plate 2-nickel-based alloy plate 3 from top to bottom.

[0026] Secondly, the center 4 of the laser beam spot is located on the side of the nickel-based alloy 3 , offset by a certain ...

Embodiment 2

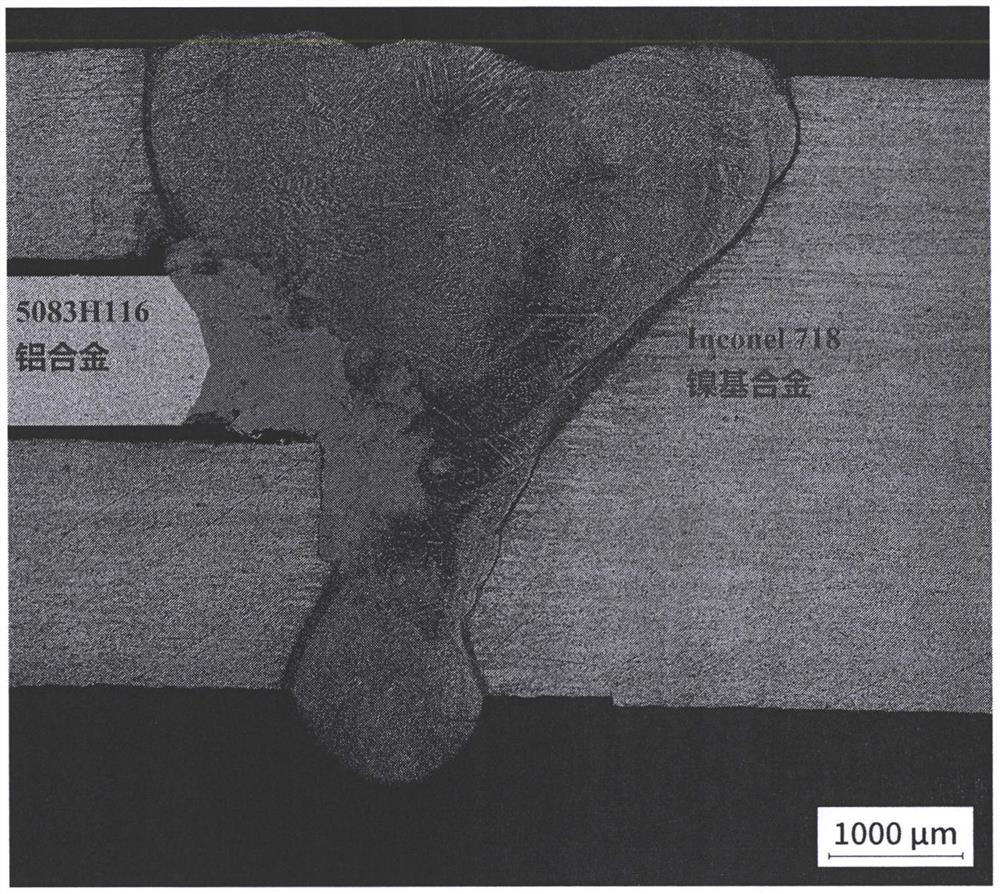

[0030] The welding method of this embodiment is basically the same as that of Embodiment 1, except that the distance d between the laser beam and the center line of the upper surface in this embodiment is 0.5 mm. Test the tensile properties of the welded joints. The fracture position of the sample is located on the side of the weld between the upper nickel-based alloy and the middle aluminum alloy. The tensile strength of the joint at room temperature reaches 171-184MPa.

Embodiment 3

[0032] The welding method of this embodiment is basically the same as that of Embodiment 1, except that the laser power in this embodiment is 2.3kW, and the welding speed is 0.8m / min. Test the tensile properties of the welded joints. The fracture position of the sample is located on the side of the weld between the upper nickel-based alloy and the middle aluminum alloy. The tensile strength of the joint at room temperature reaches 159-171MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com