Rotor hole pushing equipment capable of avoiding excessive hole forming for three-phase motor machining

A three-phase motor and rotor technology, applied in metal processing equipment, metal processing, milling machine equipment, etc., can solve problems such as excessive opening, milling cutter detachment, weak control force of milling cutter and its rotating shaft, and improve stability , to avoid the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

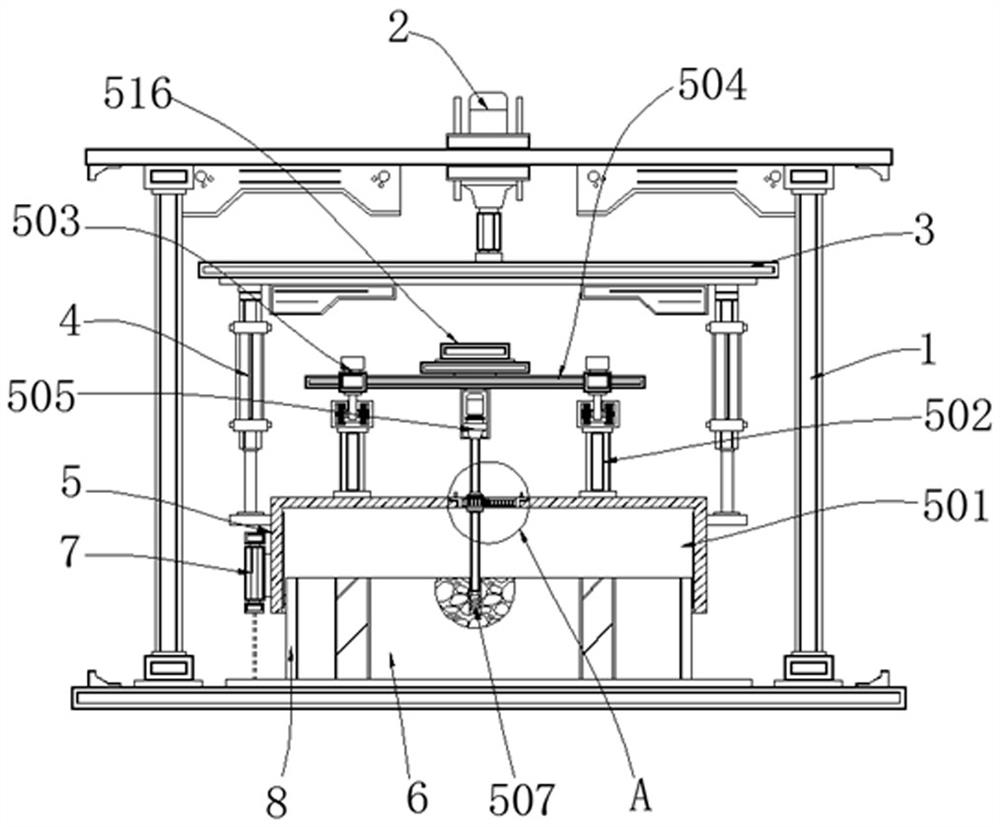

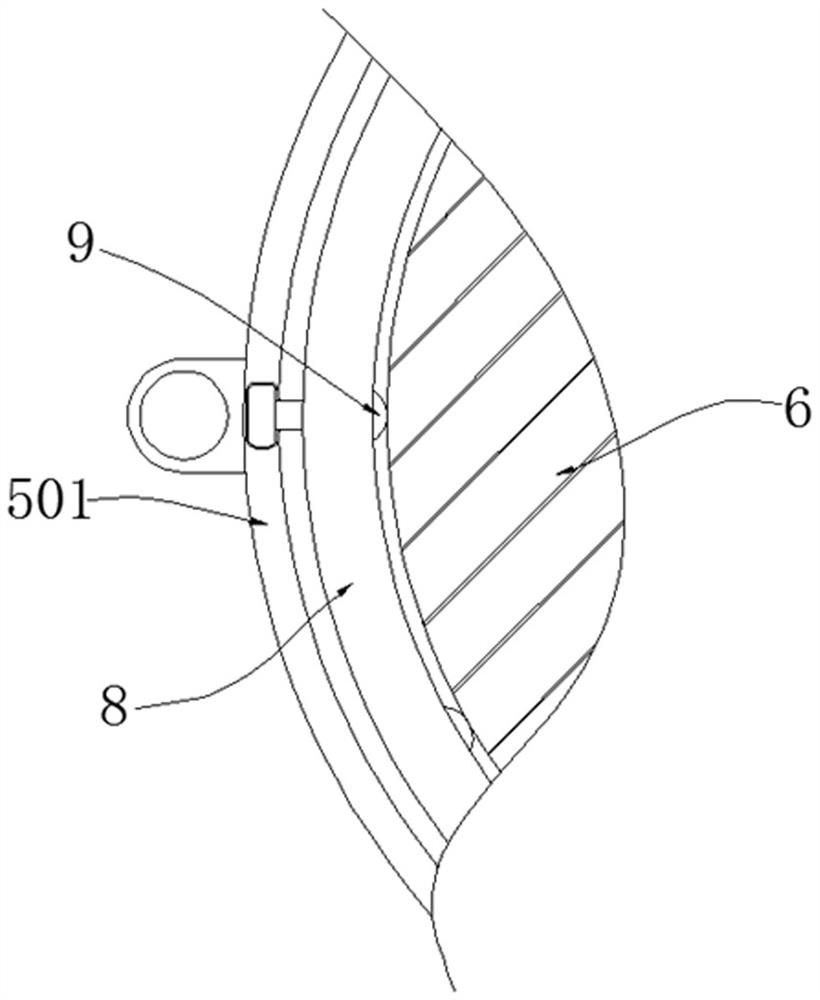

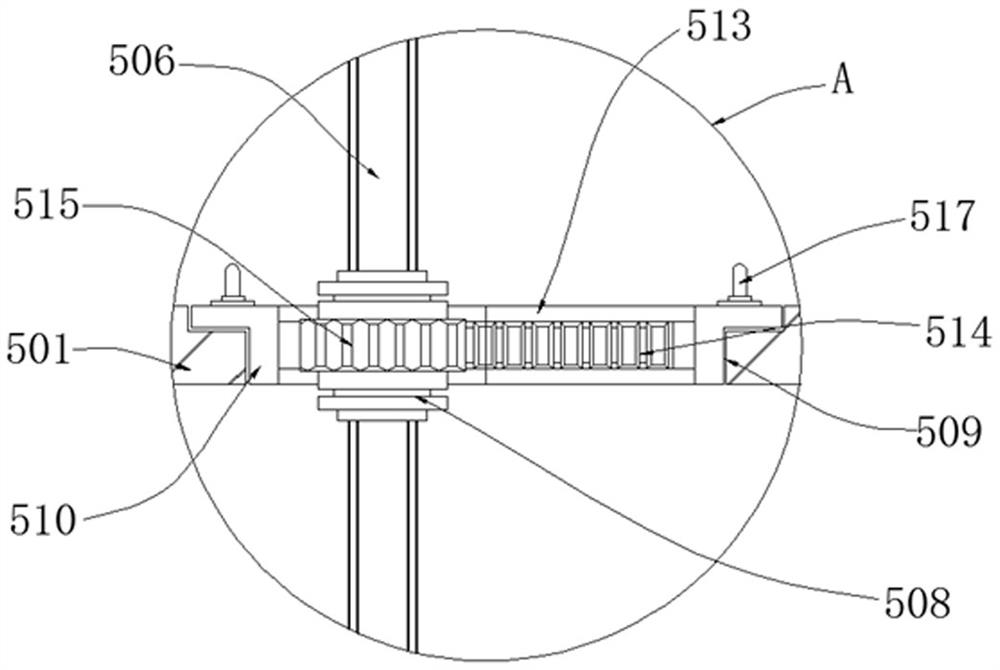

[0023] like Figure 1-5 As shown, the present invention provides a technical solution: a rotor pushing device for three-phase motor processing that can avoid excessive drilling, including a processing frame 1 and a drilling assembly 5, the top of the processing frame 1 is equipped with an adjusting motor 2, And the bottom of the adjustment motor 2 is connected with a transmission disc 3, the bottom surface of the transmission disc 3 is provided with an electric lifting rod 4, and the opening assembly 5 is fixed on the bottom of the electric lifting rod 4, and the opening assembly 5 includes a sleeve 501, a Y Shaft double slide rail 502, first block 503, second block 504, drive motor 505, rotating shaft 506, milling cutter head 507, bearing 508, placement groove 509, first shaping part 510, card slot 511, card post 512, The second shaping part 513, the tooth edge 514 of the shaping part, the connecting tooth edge 515 and the X-axis double slide rail 516, the two sides of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com