Column insulator and manufacturing method thereof

An insulator and column type technology, applied in the field of column type insulators and their production, can solve the problems of reduced reclosing success rate, long-term power failure, large losses, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

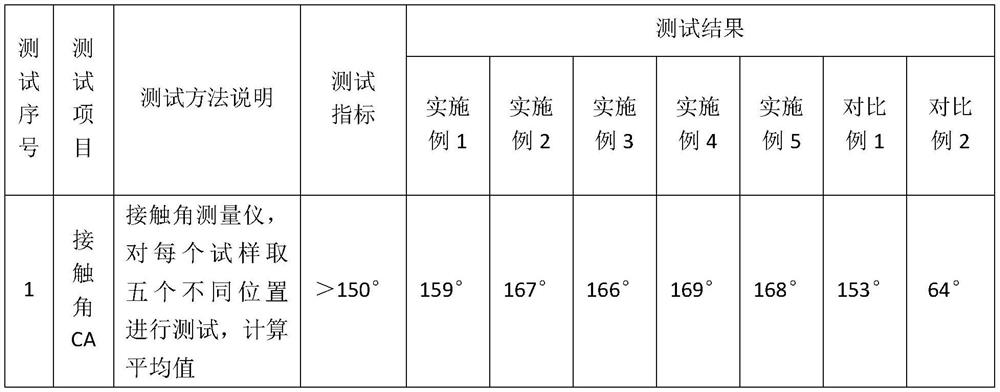

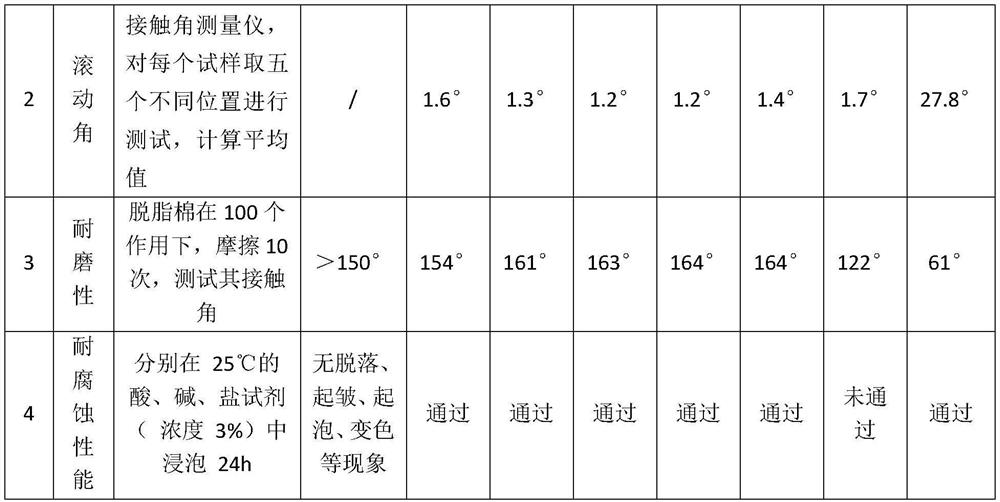

Examples

Embodiment 1

[0029] A column insulator, comprising an insulator base and a first protective layer and a second protective layer sequentially covering the surface of the insulator base, wherein,

[0030] The raw materials for forming the first protective layer are the following parts by weight: 2 parts of silicon carbide, 5 parts of polyvinyl alcohol, 5 parts of ash clay / glass fiber composite material, 2 parts of wollastonite, diatomaceous earth / nanometer calcium carbonate Composite material 6 parts.

[0031] The raw materials for forming the second protective layer are the following parts by weight: 20 parts of modified epoxy resin / montmorillonite composite material, 3 parts of modified hydrophobic silicon dioxide, 5 parts of polyacrylate, and 2 parts of silicone acrylic emulsion.

[0032] Wherein, the preparation method of diatomite / nano-calcium carbonate composite material comprises: mixing 3g cyclohexane and 4g triethylamine to prepare a solution, then adding 0.8g tetrabutyl titanate an...

Embodiment 2

[0041] A column insulator, comprising an insulator base and a first protective layer and a second protective layer sequentially covering the surface of the insulator base, wherein,

[0042] The raw materials for forming the first protective layer are the following parts by weight: 2.5 parts of silicon carbide, 5.2 parts of polyvinyl alcohol, 6 parts of ash clay / glass fiber composite material, 2.5 parts of wollastonite, diatomaceous earth / nanometer calcium carbonate Composite material 7 parts.

[0043] The raw materials for forming the second protective layer are the following parts by weight: 22 parts of modified epoxy resin / montmorillonite composite material, 3.5 parts of modified hydrophobic silicon dioxide, 6 parts of polyacrylate, and 2 parts of silicone acrylic emulsion.

[0044] Wherein, the preparation method of diatomite / nano-calcium carbonate composite material comprises: mixing 3.2g cyclohexane and 4.2g triethylamine to prepare a solution, then dropping into 0.85g te...

Embodiment 3

[0053] A column insulator, comprising an insulator base and a first protective layer and a second protective layer sequentially covering the surface of the insulator base, wherein,

[0054] The raw materials for forming the first protective layer are the following parts by weight: 3 parts of silicon carbide, 5.5 parts of polyvinyl alcohol, 7.5 parts of ash clay / glass fiber composite material, 3 parts of wollastonite, diatomaceous earth / nanometer calcium carbonate Composite material 9 parts.

[0055] The raw materials for forming the second protective layer are the following parts by weight: 25 parts of modified epoxy resin / montmorillonite composite material, 4 parts of modified hydrophobic silicon dioxide, 7 parts of polyacrylate, and 2.5 parts of silicone acrylic emulsion.

[0056] Wherein, the preparation method of diatomite / nano-calcium carbonate composite material comprises: mixing 3.5g cyclohexane and 4.5g triethylamine to prepare a solution, then dropping into 0.9g tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com