Nonmetal heat preservation composite pipe

A thermal insulation composite, non-metallic technology, applied in the direction of thermal insulation, protection of pipes and pipes through thermal insulation, etc., can solve the defects of strength, thermal insulation, surface tensile and tear resistance, shorten the service life of polyethylene pipes, environmental and Condition restrictions and other issues to achieve the effect of enhancing stability and durability, expanding additional functionality, and improving compressive strength and tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be described in further detail below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than an exhaustive list of all the embodiments. Also, the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict.

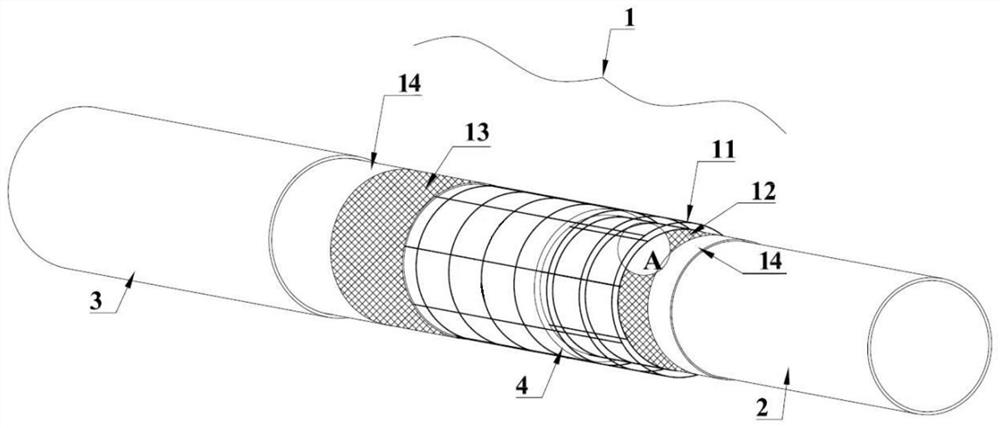

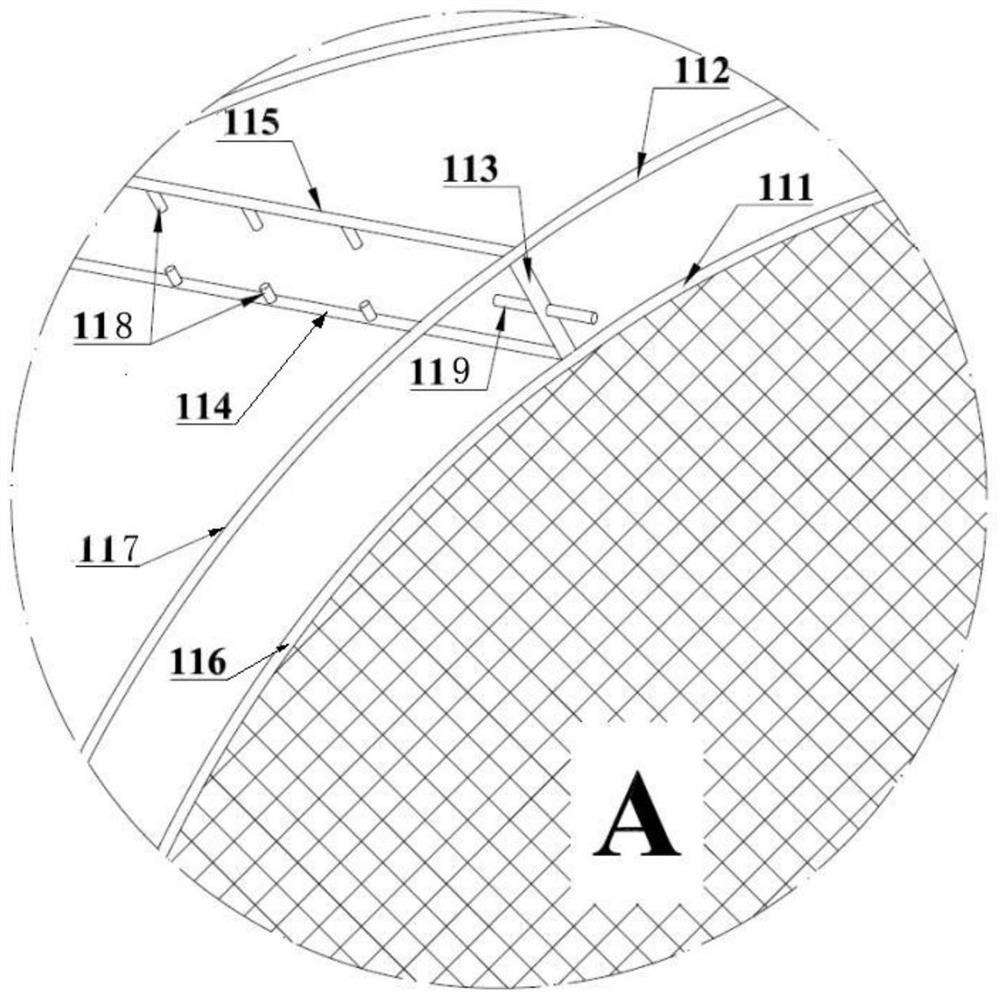

[0032] figure 1 A non-metal thermal insulation composite pipe according to an embodiment of the present invention is schematically shown, and the non-metal thermal insulation composite pipe includes a transport layer 2 . The conveying layer 2 is a tubular structure, the interior of which is used for conveying materials. An outer layer 3 is provided on the outside of the transport layer 2, a strength structure 1 between the transport layer 2 and the outer layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com