Rare earth modified graphene copper-based composite material and preparation method and application thereof

A technology of copper-based composite materials and rare earth modification, which is applied in the field of materials to achieve the effect of reducing electrical conductivity and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

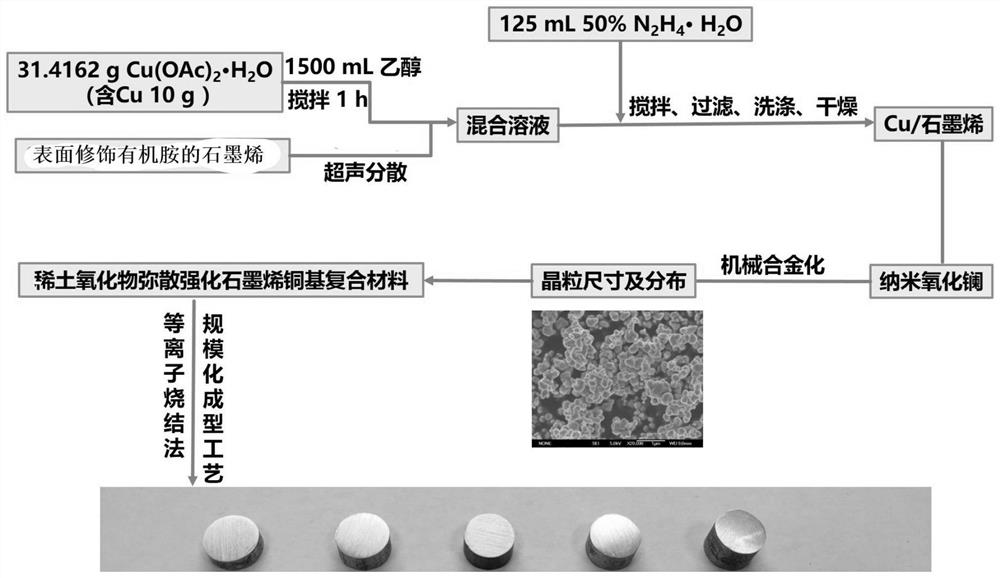

Method used

Image

Examples

Embodiment 1

[0047] (1) Weigh 1g of flake graphite material and 200mg of dodecylamine, measure 10ml of sec-butanol, put flake graphite, dodecylamine and sec-butanol into a 100ml ball mill jar, and ball mill at a speed of 400r / min After 24 hours, the ball mill products were separated in different centrifugal intervals (0-2000r / min, 2000-6000r / min, 6000-9000r / min, >9000r / min) to obtain graphene products in different centrifugal intervals, and then 9500r / min The centrifugal product of / min is centrifuged and washed, and circulates 3 times, and the graphene product of last dodecylamine modification is redispersed in sec-butanol for subsequent use, promptly obtains the graphene dispersion liquid of surface-modified dodecylamine.

[0048] (2) The copper mirror reaction in the graphene dispersed organic system was used to prepare the graphene-copper matrix composite material. Firstly, 31.4162g Cu(CH 3 COO) 2 ·H 2 O was dissolved in 50 mL of sec-butanol to form Cu(CH 3 COO) 2 ·H 2 O organic s...

Embodiment 2

[0051] (1) Weigh 1g of flake graphite material and 200mg of dodecylamine, measure 10ml of sec-butanol, put flake graphite, dodecylamine and sec-butanol into a 100ml ball mill jar, and ball mill at a speed of 400r / min After 24 hours, the ball mill products were separated in different centrifugal intervals (0-2000r / min, 2000-6000r / min, 6000-9000r / min, >9000r / min) to obtain graphene products in different centrifugal intervals, and then 8000r / min The centrifuged products in different intervals / min were centrifuged and washed, and circulated for 3 times, and the last dodecylamine-modified graphene product was redispersed in sec-butanol for subsequent use, to obtain a surface-modified graphene dispersion of dodecylamine.

[0052] (2) The graphene-copper matrix composite was prepared by using the copper mirror reaction in the graphene-dispersed organic system. First, 15.7081g Cu(CH 3 COO) 2 ·H 2 O was dissolved in 10 mL of sec-butanol to form Cu(CH 3 COO) 2 ·H 2 O organic soluti...

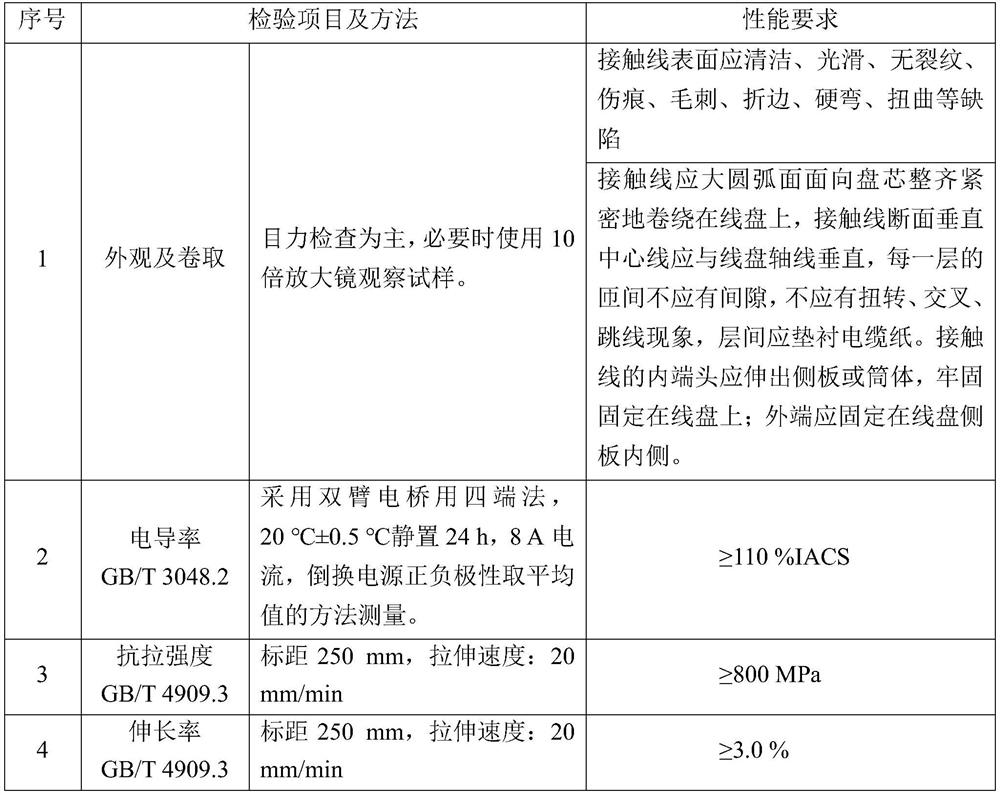

experiment example

[0055] The rare earth modified graphene copper-based composite material obtained by the embodiment is prepared as a contact wire, and its performance is tested according to corresponding national standards, and its inspection items and methods and performance requirements are as shown in table 1:

[0056] Table 1 Reliability indicators and application environment indicators of graphene copper-based materials

[0057]

[0058] The test results show that: the contact angle between rare earth oxide and copper substrate is less than 60 degrees, the grain size is less than 1 micron, the material strength is not less than 800MPa, the conductivity is not less than 110IACS%, and the elongation is not less than 3.0%. It is superior to the level of similar foreign products, and its advantages can occupy a clear advantage in the high-speed railway market, with huge economic benefits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com