Method for selectively extracting scandium from laterite-nickel ore by adopting sulfuric acid roasting-water leaching method

A technology of laterite nickel ore and sulfuric acid roasting, applied in the field of metallurgical engineering, to achieve the effects of easy control, clean and efficient extraction, scandium recovery rate and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The composition of laterite nickel ore treated in the present embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.%, Cr 1.23wt.%.

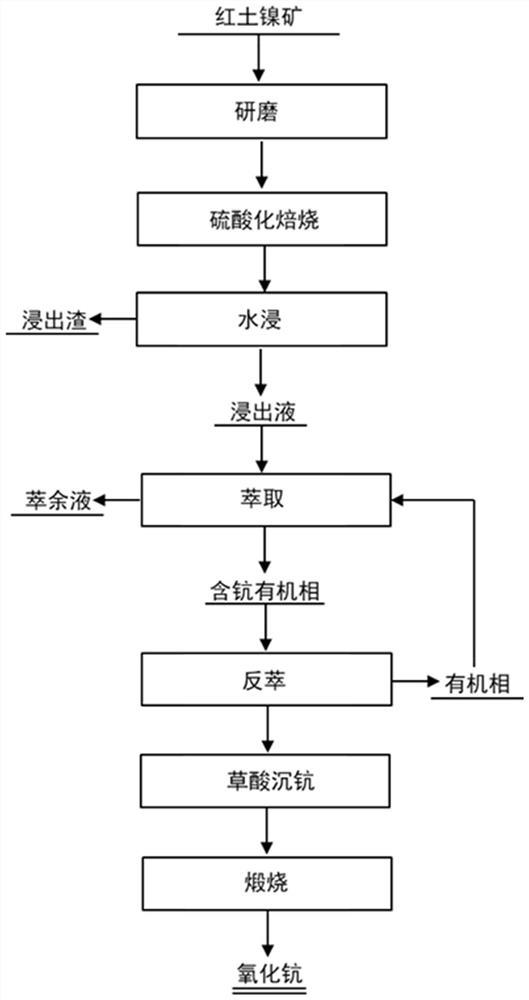

[0035] The present embodiment adopts sulfuric acid roasting - water immersion method to selectively extract scandium from laterite nickel ore, the process flow such as Figure 1 shown, including the following steps:

[0036] (1) Grinding: the laterite nickel ore is crushed and finely ground to obtain laterite nickel ore with a particle size of -0.074mm;

[0037] (2) Sulfation roasting: the laterite nickel ore obtained in step (1) is fully mixed with concentrated sulfuric acid, wherein the ratio of concentrated sulfuric acid to laterite nickel ore is 0.5mL / g, and then the mixture is placed in a tubular atmosphere furnace at 600 °C for roasting, roasting for 2.0h, to obtain the roasting product;

[0038](3) Water immersion: the calcination product obtained in step (2) is placed in water for lea...

Embodiment 2

[0044] The composition of laterite nickel ore treated in the present embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.%, Cr 1.23wt.%.

[0045] The present embodiment adopts sulfuric acid roasting - water immersion method to selectively extract scandium from laterite nickel ore, the process flow such as Figure 1 shown, including the following steps:

[0046] (1) Grinding: the laterite nickel ore is crushed and finely ground to obtain laterite nickel ore with a particle size of -0.074mm;

[0047](2) Sulfation roasting: the laterite nickel ore obtained in step (1) is fully mixed with concentrated sulfuric acid, wherein the ratio of concentrated sulfuric acid to laterite nickel ore is 0.3mL / g, and then the mixture is placed in a tubular atmosphere furnace for roasting, the roasting temperature is 800 °C, the roasting time is 2.0h, and the roasting product is obtained;

[0048] (3) Water leaching: the calcined product obtained in...

Embodiment 3

[0054] The composition of laterite nickel ore treated in the present embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.%, Cr 1.23wt.%.

[0055] The present embodiment adopts sulfuric acid roasting - water immersion method to selectively extract scandium from laterite nickel ore, the process flow such as Figure 1 shown, including the following steps:

[0056] (1) Grinding: the laterite nickel ore is crushed and finely ground to obtain laterite nickel ore with a particle size of -0.074mm;

[0057] (2) Sulfation roasting: the laterite nickel ore obtained in step (1) is fully mixed with concentrated sulfuric acid, and the ratio of concentrated sulfuric acid to laterite nickel ore is 1.0mL / g, and then the mixture is placed in a tubular atmosphere furnace for roasting, the roasting temperature is 500 °C, the roasting time is 3.0h, and the roasting product is obtained;

[0058] (3) Water leaching: the calcination product obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com