Process for extracting oil

A technology for extracting oil and grease, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of large solvent loss, large loss, and long extraction time, and achieve low energy and solvent consumption, high input-output ratio, and comprehensive The effect of high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

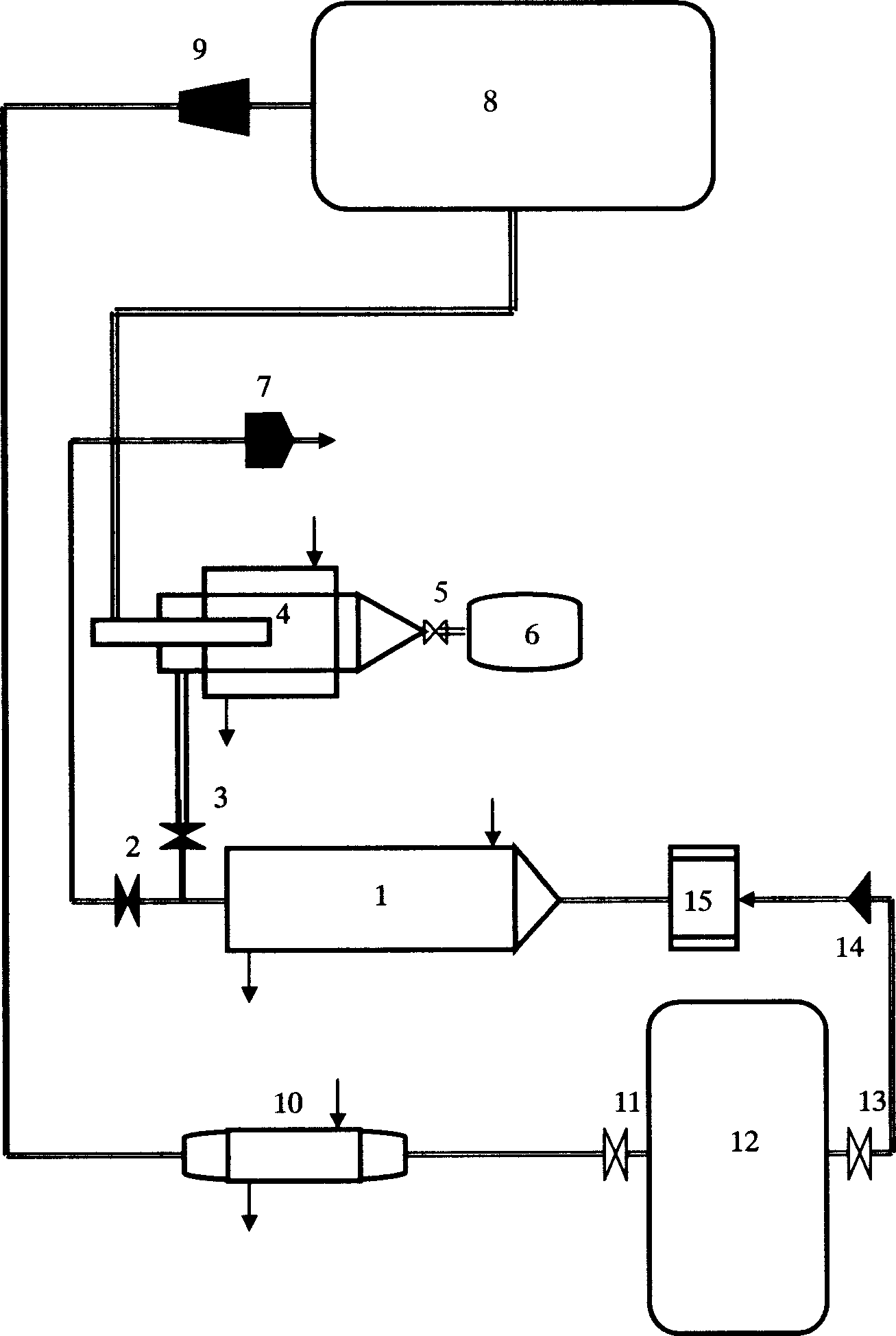

[0023] Put 901 kg of tung seeds crushed to 10 meshes into the extraction kettle 1, close the valves 3, 5, 11, and 13, open the high vacuum butterfly valve 2, start the vacuum pump 7 to remove the air in the extraction kettle 1, and close the high vacuum butterfly valve 2 , open the valve 13, start the metering pump 14, the liquid in the liquid dimethyl ether storage tank 12 is heated by the exchanger 15, adopt the liquid dimethyl ether as the extraction solvent, and pass into the extraction by the weight ratio of material: solvent=1:2 In the kettle 1, under the conditions of a pressure of 5 kg and an extraction temperature of 30°C, after extraction for 30 minutes, open the decompression valve 3, and under the conditions of a pressure of 1 kg and a temperature of 20°C, the liquid is separated by the separation kettle 4 Grease and dimethyl ether gas are discharged, and the dimethyl ether gas enters the gas storage tank 8, and the compressor 9 is started. After the dimethyl ether ...

Embodiment 2

[0028] Put 685 kg of tung tree seeds crushed to 40 objects into the extraction kettle 1, close the valves 3, 5, 11, and 13, open the high vacuum butterfly valve 2, start the vacuum pump 7 to remove the air in the extraction kettle 1, close the high vacuum butterfly valve 2, Open the valve 13, start the metering pump 14, heat the liquid in the liquid dimethyl ether storage tank 12 through the exchanger 15, adopt the liquid dimethyl ether as the extraction solvent, and pass it into the extraction kettle at a weight ratio of material: solvent=1:24 In 1, under the conditions of a pressure of 30 kg and an extraction temperature of 90°C, after extraction for 120 minutes, the decompression valve 3 is opened, and the liquid is separated through the separation tank 4 under the conditions of a pressure of 5 kg and a temperature of 60°C. Grease and dimethyl ether gas, dimethyl ether gas enters the gas storage tank 8, starts the compressor 9, after the dimethyl ether gas is compressed, it ...

Embodiment 3

[0033] Put 362 kg of tung tree seed shells crushed to 25 mesh into extraction kettle 1, close valves 3, 5, 11, and 13, open high vacuum butterfly valve 2, start vacuum pump 7 to extract the air in extraction kettle 1, and close high vacuum butterfly valve 2 , open the valve 13, start the metering pump 14, the liquid in the liquid dimethyl ether storage tank 12 is heated through the exchanger 15, adopt the liquid dimethyl ether as the extraction solvent, and pass into the extraction by the weight ratio of material: solvent=1:3 In the kettle 1, under the conditions of a pressure of 8 kg and an extraction temperature of 35°C, after extraction for 40 minutes, the pressure reducing valve 3 is opened, and the liquid is separated by the separation kettle 4 under the conditions of a pressure of 5 kg and a temperature of 50°C. Grease and dimethyl ether gas are discharged, and the dimethyl ether gas enters the gas storage tank 8, and the compressor 9 is started. After the dimethyl ether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com