Process method for treating coal chemical industry wastewater

A technology of coal chemical wastewater and process method, applied in water/sewage treatment, aerobic process treatment, natural water body treatment, etc., can solve the problems of multiple resources, unfavorable energy saving, and increase of wastewater treatment cost, so as to improve treatment efficiency, Excellent extraction effect and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

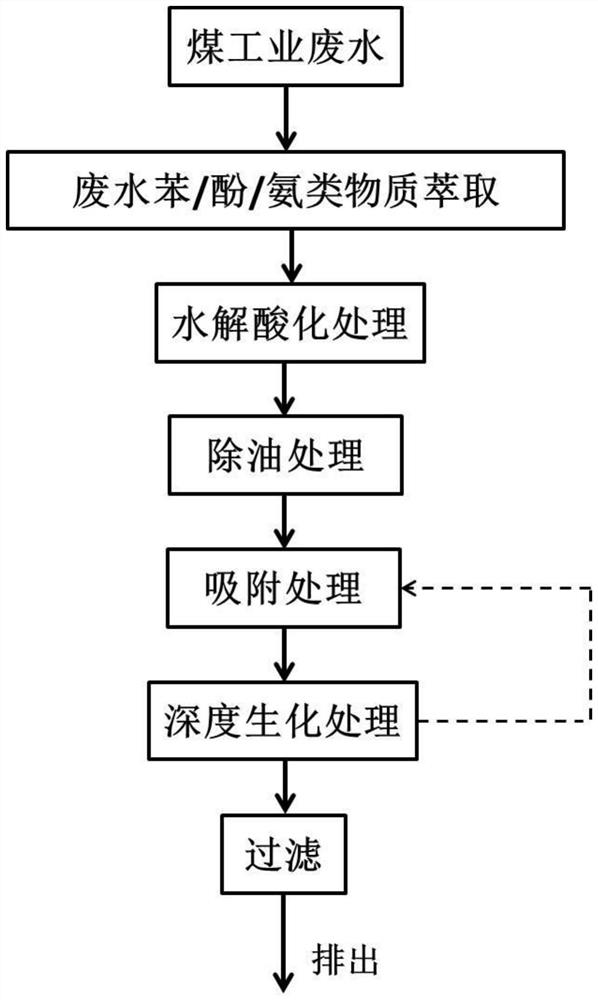

[0021] A process for the treatment of coal chemical wastewater, specifically comprising the following steps:

[0022] S1: Use an extractant to extract phenol / ammonia / benzene substances from coal chemical industry wastewater. The preparation of the extractant includes the following steps: 30 parts of N503 extractant, 60 parts of kerosene, 20 parts of tributyl phosphate, 10 parts Parts of dioctyl sebacate and 30 parts of dimethyl carbonate.

[0023] S2: The waste water treated in step S1 is subjected to hydrolysis and acidification treatment, and the pH value of the waste water is adjusted to 7.

[0024] S3: Transport the waste water treated in step S2 to the oil-water separation device for oil removal treatment.

[0025] S4: performing adsorption treatment on the waste water after degreasing and separation in step S3. The adsorption treatment uses adsorption materials to perform adsorption treatment on the wastewater. The preparation of the adsorption materials includes:

[0...

Embodiment 2

[0030] A process for the treatment of coal chemical wastewater, specifically comprising the following steps:

[0031] S1: Use an extractant to extract phenol / ammonia / benzene substances from coal chemical industry wastewater. The preparation of the extractant includes the following steps: 40 parts of N503 extractant, 70 parts of kerosene, 30 parts of tributyl phosphate, 15 parts Parts of dioctyl sebacate and 45 parts of dimethyl carbonate.

[0032] S2: The waste water treated in step S1 is subjected to hydrolysis and acidification treatment, and the pH value of the waste water is adjusted to 8.

[0033] S3: Transport the waste water treated in step S2 to the oil-water separation device for oil removal treatment.

[0034] S4: performing adsorption treatment on the waste water after degreasing and separation in step S3. The adsorption treatment uses adsorption materials to perform adsorption treatment on the wastewater. The preparation of the adsorption materials includes:

[0...

Embodiment 3

[0039] A process for the treatment of coal chemical wastewater, specifically comprising the following steps:

[0040] S1: Use an extractant to extract phenol / ammonia / benzene substances from coal chemical industry wastewater. The preparation of the extractant includes the following steps: 36 parts of N503 extractant, 60 parts of kerosene, 24 parts of tributyl phosphate, 12 parts Parts of dioctyl sebacate and 45 parts of dimethyl carbonate.

[0041] S2: The waste water treated in step S1 is subjected to hydrolysis and acidification treatment, and the pH value of the waste water is adjusted to 7.4.

[0042] S3: Transport the waste water treated in step S2 to the oil-water separation device for oil removal treatment.

[0043] S4: performing adsorption treatment on the waste water after degreasing and separation in step S3. The adsorption treatment uses adsorption materials to perform adsorption treatment on the wastewater. The preparation of the adsorption materials includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com