Anti-corrosion and anti-skid resin coating powder as well as preparation method and application thereof

A technology of resin coating and epoxy resin powder, which is applied in the direction of anti-corrosion coating, epoxy resin coating, polyester coating, etc., can solve the problems that people are prone to slipping, reduce the friction force of epoxy floor paint, etc., and achieve the reduction of two Secondary damage, excellent elasticity, and the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

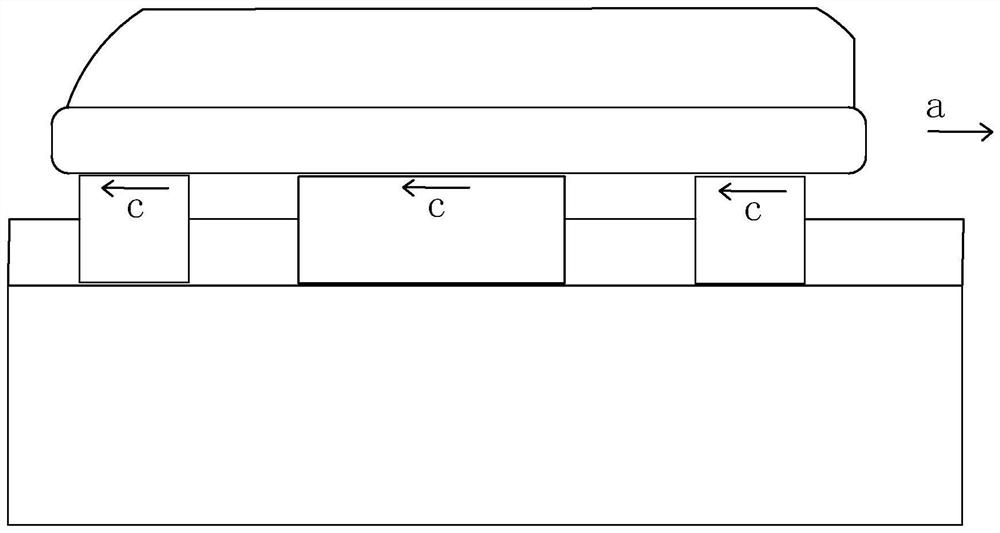

[0047] A cylindrical nitrile rubber strip, which is cut from a nitrile rubber plate, has a length of 3 cm and a cross-sectional diameter of 1.5 cm.

preparation example 2

[0049]A quadrangular prism-shaped nitrile rubber strip, which is cut from a nitrile rubber plate, has a length of 3 cm, a square cross section, and a side length of 1.5 cm.

preparation example 3

[0051] A triangular prism-shaped nitrile rubber strip, which is cut from a nitrile rubber plate, has a length of 3 cm, and a cross-section of an isosceles triangle, and the length of the midline of the bottom of the isosceles triangle is 1.5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com