Ti-Al-V-Mo series metal powder core flux-cored wire and preparation method thereof

A technology of ti-al-v-mo and flux-cored welding wire, which is applied in the field of welding materials, can solve the problems of high preparation costs, achieve the effects of low cost, refine weld grains, and increase weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

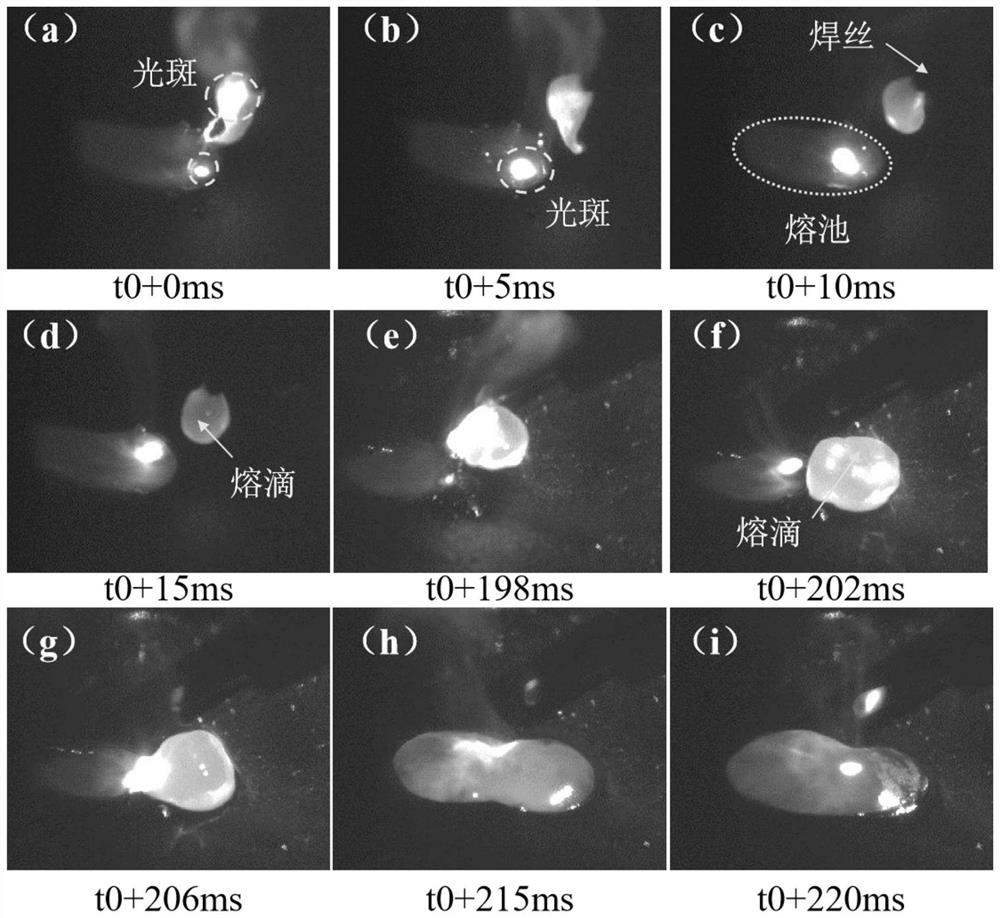

Method used

Image

Examples

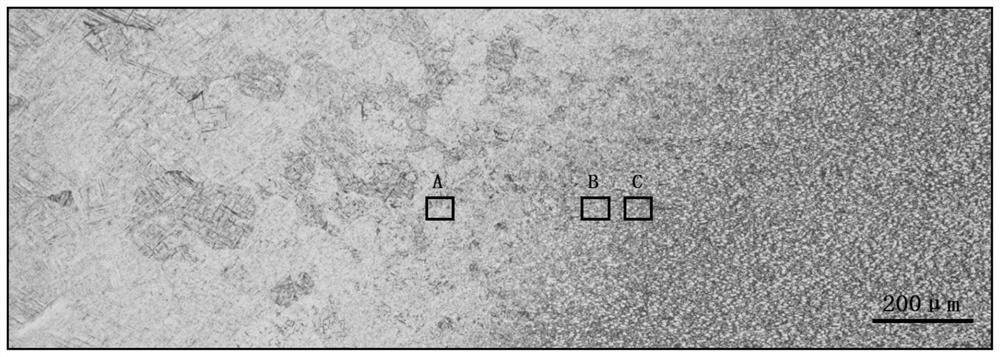

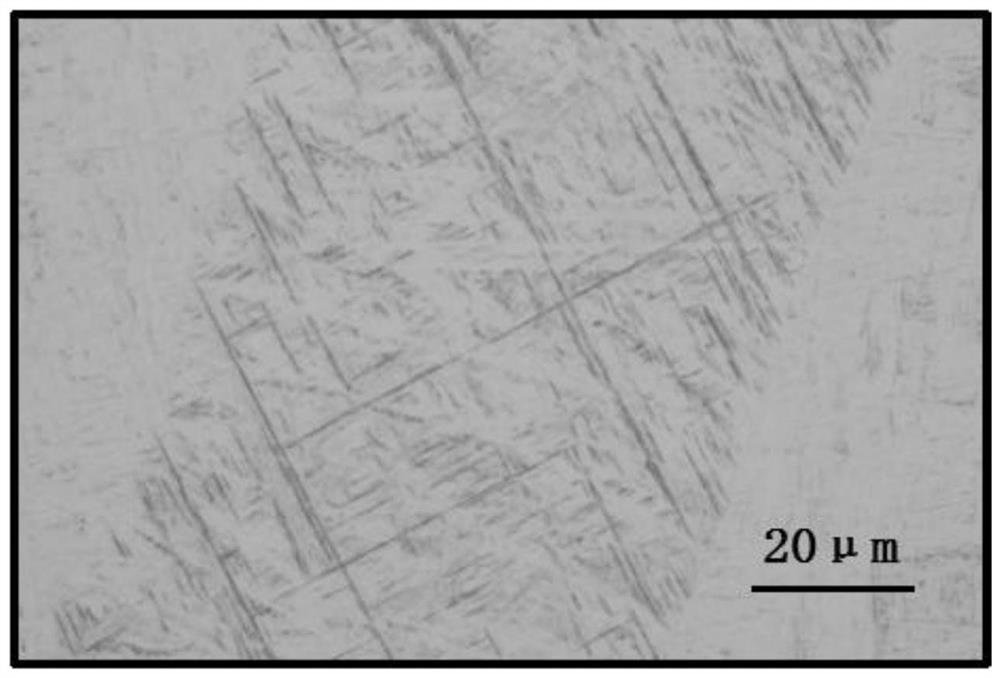

Embodiment 1

[0034]Embodiment 1, a kind of Ti-Al-V-Mo series metal powder flux-cored welding wire of the present embodiment is composed of Ti-10Mo-4Nb-4V sheath and the flux core filled therein, wherein the flux core is made of vanadium powder by mass fraction 5%, 12% of aluminum powder, 3% of molybdenum powder, 3% of iron powder and the balance of titanium powder, the filling rate of the drug core is 22%, and the particle size of the aluminum powder and titanium powder is 80~ 120 mesh, the granularity of described vanadium powder, molybdenum powder, iron powder is 80~200 mesh, described Ti-10Mo-4Nb-4V sheath (tensile strength is 810MPa, yield strength is 560MPa, elongation after breaking is 44% ) has a thickness of 0.45mm, a width of 7mm, and a length of 40m. The chemical composition and mass percentage of the Ti-10Mo-4Nb-4V skin are: Mo: 10.05%, Nb: 4.09%, V: 4.01%, Al: 3.02%, H ≤ 0.013%, N ≤ 0.015%, O ≤ 0.010%, and the balance is Ti. The chemical composition and mass percentage of the d...

Embodiment 2

[0040] Embodiment 2: the present embodiment is different from embodiment 1 in that: the medicine core is mixed by mass fraction by vanadium powder 7%, aluminum powder 15%, molybdenum powder is 5%, iron powder 3.5% and surplus titanium powder, The filling rate of the flux core is 24%, and the chemical composition and mass percentage of the deposited metal after the flux cored wire is welded are: V: 7.07%, Al: 13.2%, Mo: 8.45%, Fe: 2.98 %, Nb: 1.0%, and the balance is Ti. Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com