Filter chip and processing method thereof

A processing method and filter technology, applied in the field of filters, can solve problems such as damage to resonators in chips, impact on filter performance, and easy damage to resonators, so as to improve resonance energy efficiency, strong anti-interference effect, and reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

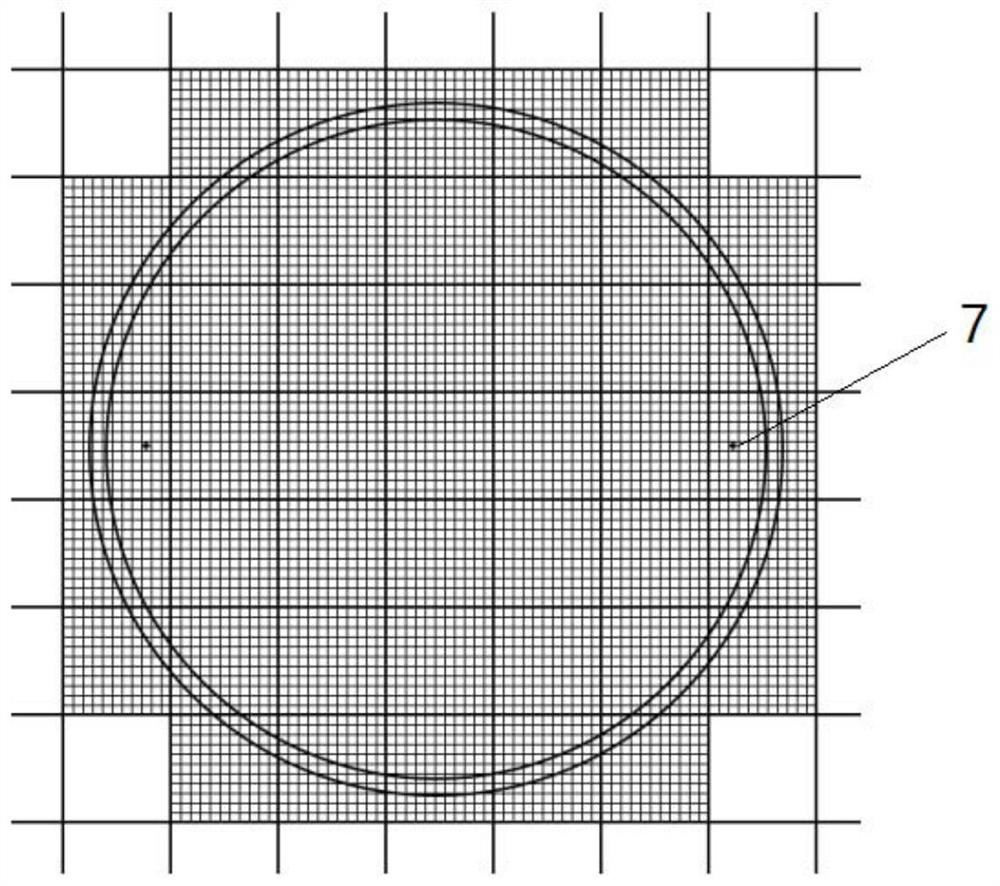

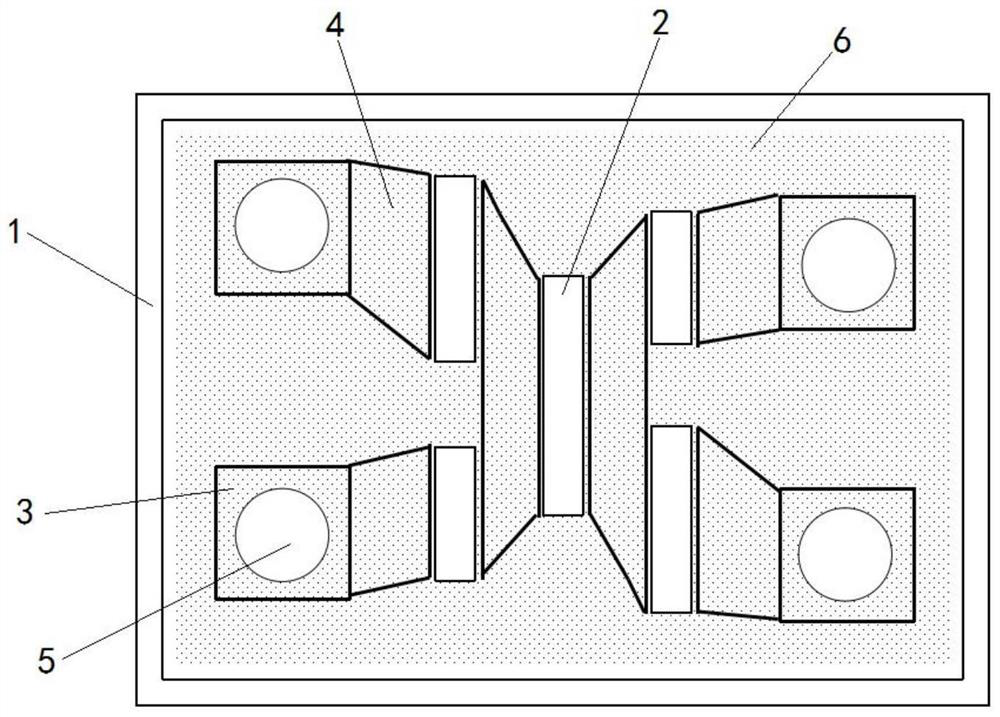

[0032] like Figure 1~2 As shown, a filter chip includes a wafer, and an effective area of the chip is provided on the wafer; a scribing line 1 is provided outside the effective area of the chip; a resonator 2 and a pad 3 are provided in the effective area of the chip; The pad 3 is connected to the resonator 2 through the metal line 4; solder balls 5 are planted in the ball planting area of the pad 3;

Embodiment 2

[0034] A processing method for a filter chip, comprising the following steps:

[0035] Step 1: Design and process the wafer of the filter; the wafer structure is as Figure 1~2 As shown, determine the alignment coordinates 7; process the scribe line on the wafer; install resonators, metal lines and pads in the effective area of the chip; covered with a silicon dioxide protective layer;

[0036] Step 2: Implanting solder balls 5 on the pads 3 by means of bumping processing.

[0037] Before the bumping process, it is necessary to design the photoresist mask and the stencil for brushing and planting balls.

[0038] (1) Design and process the photoresist mask plate: open a window at the position corresponding to the photoresist mask plate and the ball planting area of the pad;

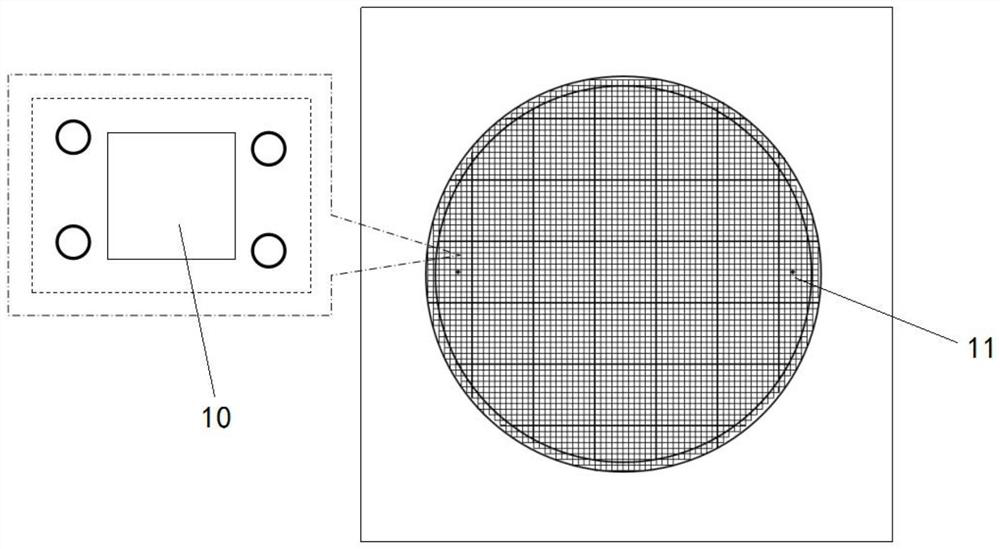

[0039] (2) Design and process brushing and ball planting steel mesh 8, such as Figure 3-5 As shown; the brushing and ball planting steel mesh 8 is provided with an opening 9 corresponding to the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com