Preparation method and application of heat-resistant titanium alloy bolt for aerospace

An aerospace and titanium alloy technology, applied in the direction of screws, mechanical equipment, threaded fasteners, etc., can solve problems such as complex processes and affecting the heat resistance of titanium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

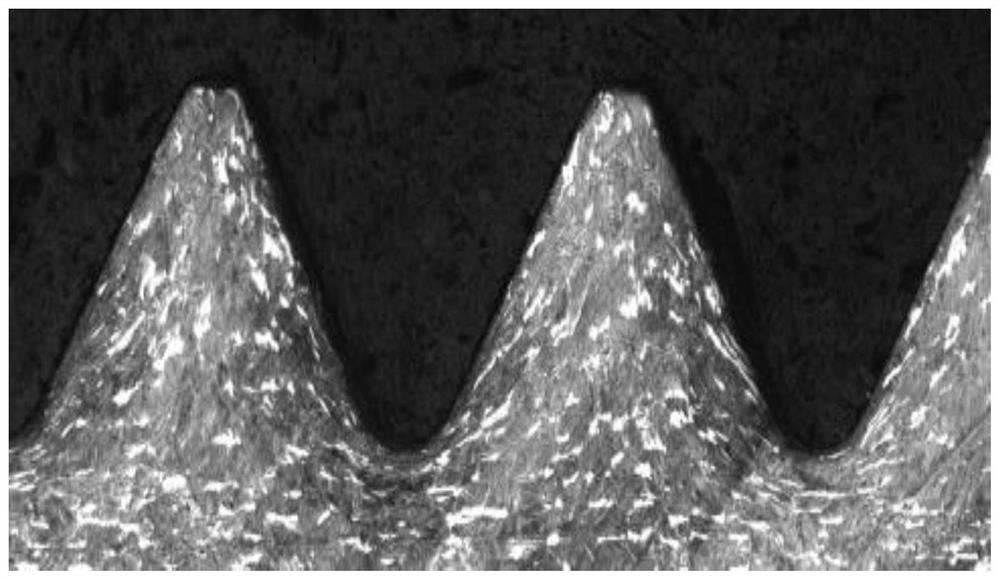

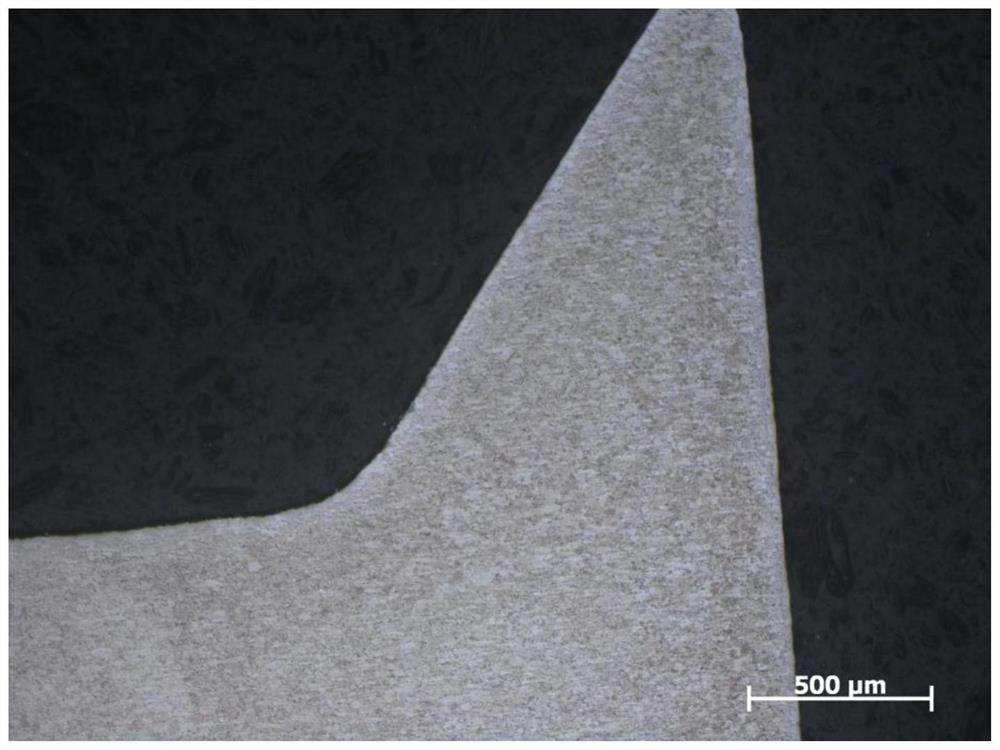

Image

Examples

Embodiment 1

[0033] A method for preparing a heat-resistant titanium alloy bolt for aerospace, comprising the following steps:

[0034] 1), choose Ti60 alloy Φ6.1mm straight wire;

[0035] 2) According to the length of the polished rod tolerance zone f9 cross recessed 100° countersunk head bolt to be prepared, cut 45mm of Φ6.1mm annealed wire as the bolt blank and send it to the multi-station hot heading machine, and make one end of the bolt blank by induction heating For a bolt head with a diameter of 12mm, the parameters of the primary induction heating process are current 1175A, the holding time is 16s, and the deformation is 50% of the total deformation; the secondary heating induction heating parameters are current 1125A, the holding time is 16s, and the deformation The deformation amount is 30% of the total deformation amount; the three-time hot heading induction heating process parameters are current 1125A, holding time 8s, and the deformation amount is 20% of the total deformation ...

Embodiment 2

[0043] A method for preparing a heat-resistant titanium alloy bolt for aerospace, comprising the following steps:

[0044] 1), choose Ti60 alloy Φ6.1mm straight wire;

[0045] 2) According to the length of the f9 hexagonal head bolts in the polished rod tolerance zone to be prepared, cut 40mm of Φ6.1mm annealed wire as the bolt blank and send it to the multi-station hot heading machine, and make one end of the bolt blank into a 12mm diameter by induction heating For the bolt head, the parameters of the induction heating process for the primary heat upsetting are current 1225A, the holding time is 8s, and the deformation is 55% of the total deformation; 25% of the amount; the process parameters of the three-time hot heading induction heating are current 1075A, holding time 16s, and the deformation amount is 20% of the total deformation amount, and the first-grade semi-finished product of Ti60 titanium alloy bolts is obtained;

[0046] 3) The first-class semi-finished product o...

Embodiment 3

[0054] A method for preparing a heat-resistant titanium alloy bolt for aerospace, comprising the following steps:

[0055] 1), choose Ti60 alloy Φ6.1mm straight wire;

[0056] 2) According to the length of the f9 hexagon head bolts in the polished rod tolerance zone to be prepared, 45mm of Φ6.1mm annealed wire is cut off as the bolt blank and sent to the multi-station hot heading machine, and one end of the bolt blank is made into a 12mm diameter by induction heating. For the bolt head, the parameters of the induction heating process for the primary heat upsetting are current 1225A, the holding time is 8s, and the deformation is 45% of the total deformation; 30% of the total amount; the process parameters of the three-time hot heading induction heating are current 1075A, holding time 16s, and the deformation amount is 25% of the total deformation amount, and the first-class semi-finished product of Ti60 titanium alloy bolts is obtained;

[0057] 3) The first-class semi-finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com