Garbage fly ash microwave sintering process based on superfine grinding technology

A technology of garbage fly ash and microwave sintering, which is used in the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of high energy consumption, increase the cost of garbage fly ash, etc. The effect of reduced processing cost and process difficulty, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

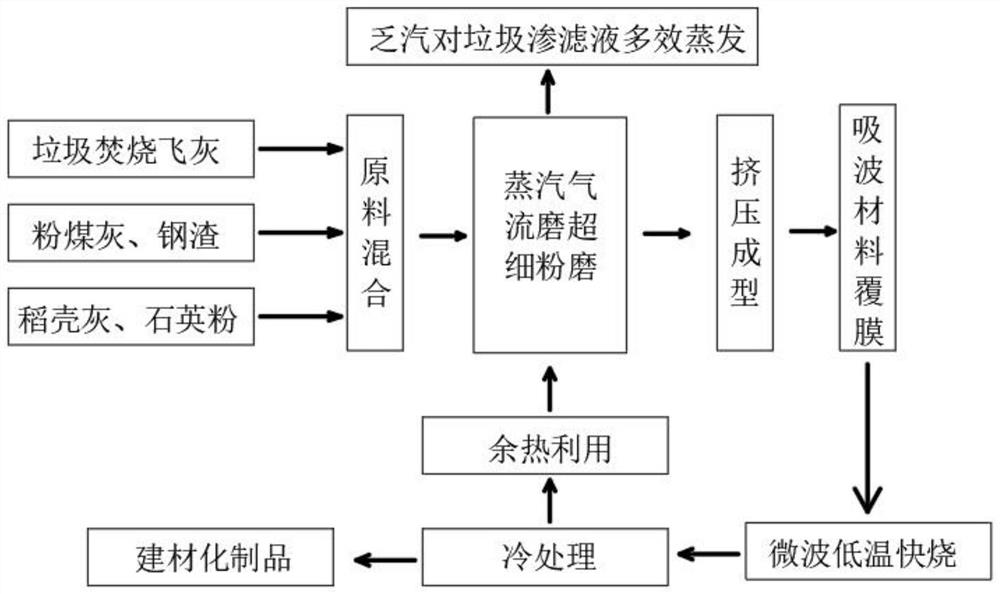

[0044] see Figure 1-2, a microwave sintering process of waste fly ash based on ultra-fine grinding technology, which mainly includes the following steps:

[0045] S1. Mixing of raw materials, the treated garbage fly ash, fly ash and rice husk ash are mixed according to the mass ratio of 60:25:15. In particular, the fly ash and rice husk ash can be made of steel slag and Quartz powder should be replaced, and the replacement ratio should not exceed one-third;

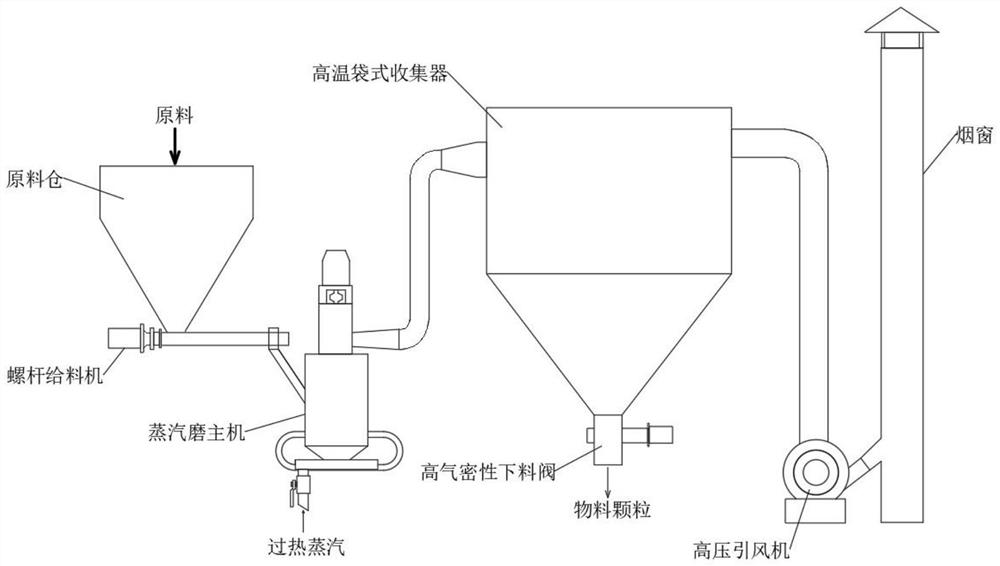

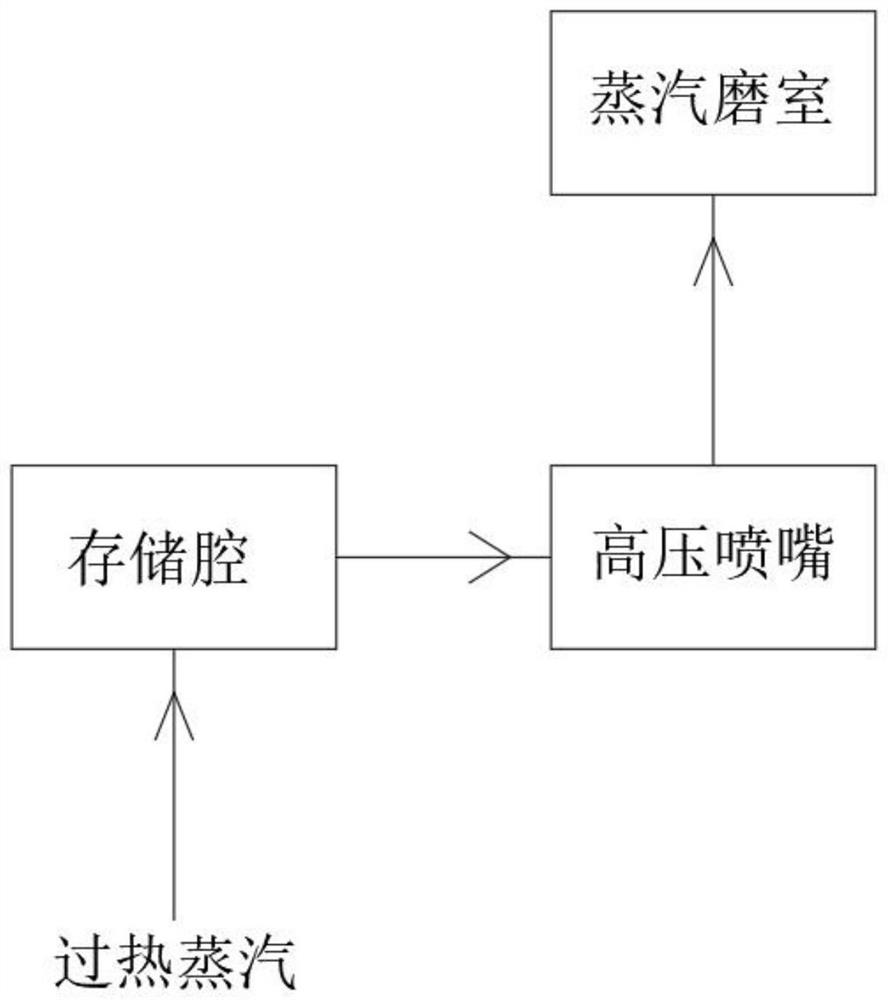

[0046] S2. Steam grinding. The raw materials mixed in S1 are put into the steam jet mill for ultra-fine grinding to obtain ultra-fine raw materials. The steam jet mill includes a raw material warehouse, a steam mill host, a high-temperature bag collector and a smoke Window, the screw feeder is connected between the raw material warehouse and the main machine of the steam mill, and the connecting pipe is connected between the main body of the steam mill and the high-temperature bag collector. A high-pressure induced dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com