Magnetic multilayer film, memory unit and memory

A storage unit and multi-layer film technology, applied in the field of magnetic field controlled resistors, electrical components, semiconductor devices, etc., can solve the problem of thermal stability factor Δ reduction, achieve high thermal stability factor, comprehensive performance improvement, and low turnover The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

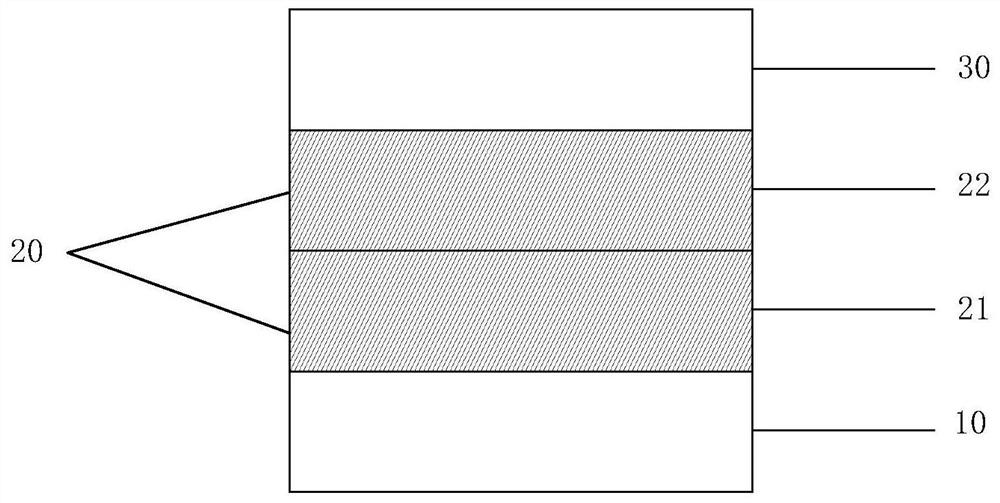

[0042] figure 1 The shown free layer includes a first magnetic layer 10 , a spacer film 20 (including a first spacer sub-film 21 , a second spacer sub-film 22 ) and a second magnetic layer 30 deposited in sequence. Wherein the first magnetic layer 10 and the second magnetic layer 30 are Co 20 Fe 55 B 25 The alloy has a thickness of 1 nm; the first spacer film 21 is W with a thickness of 0.3 nm; the second spacer film 22 is Mg with a thickness of 0.2 nm.

Embodiment 2

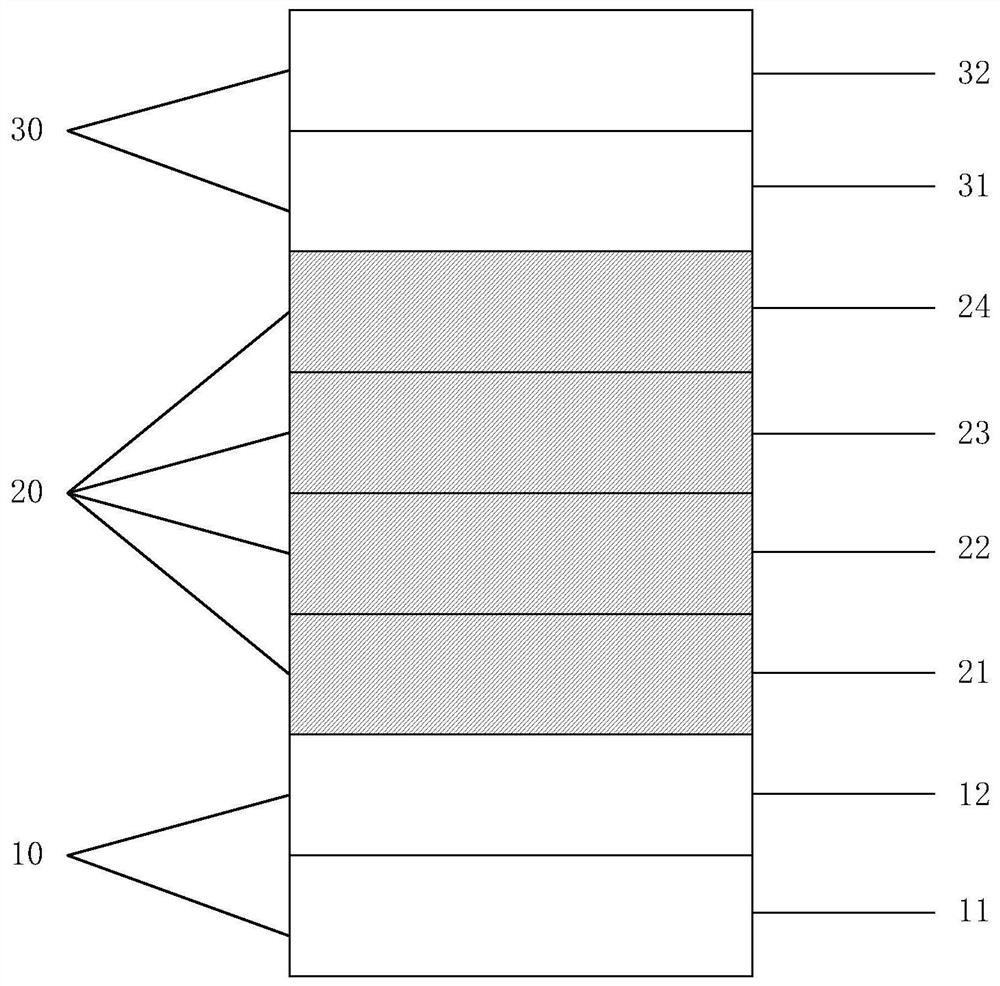

[0044] figure 2 The shown free layer includes a first magnetic layer 10 (comprising a first sub-magnetic layer 11 and a second sub-magnetic layer 12), a spacer film 20 (comprising a first spacer sub-film 21, a second spacer sub-film 22, the third spacer sub-film 23 , the fourth spacer sub-film 24 ) and the second magnetic layer 30 (including the third sub-magnetic layer 31 and the fourth sub-magnetic layer 32 ). Wherein the first sub-magnetic layer 11 is CoFe with a thickness of 0.5nm; the second sub-magnetic layer 12 is Co 20 Fe 60 B 20 Alloy with a thickness of 0.7nm; the first spacer film 21 is Al with a thickness of 0.2nm; the second spacer film 22 is Hf with a thickness of 0.3nm; the third spacer film 23 is Mg with a thickness of 0.2nm; The four-spacer film 24 is Mo with a thickness of 0.1nm; the third sub-magnetic layer 31 is Co 20 Fe 60 B 20 alloy, the thickness of which is 0.5nm; the fourth sub-magnetic layer 32 is Co 40 Fe 40 B 20 alloy with a thickness of 0...

Embodiment 3

[0046] The free layer includes a first magnetic layer (including a first sub-magnetic layer and a second sub-magnetic layer), a spacer film (including a first spacer sub-film, a second spacer sub-film, a third spacer sub-film) and a second spacer film deposited in sequence. Magnetic layers (including the third sub-magnetic layer, the fourth sub-magnetic layer and the fifth sub-magnetic layer). The first sub-magnetic layer is Co with a thickness of 0.4nm; the second sub-magnetic layer is Fe 80 B 20 , the thickness is 0.8nm; the first spacer film is Al, the thickness is 0.1nm; the second spacer film is Mo, the thickness is 0.3nm; the third spacer film is Mg, the thickness is 0.2nm; the third sub-magnetic layer It is CoFe with a thickness of 0.5nm; the fourth sub-magnetic layer is Co 30 Fe 50 B 20 , with a thickness of 0.3nm; the fifth sub-magnetic layer is Co 20 Fe 60 B 20 , with a thickness of 0.3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com