Titanium alloy thin-wall part surface crack repairing method

A technology of surface crack and repair method, applied in the direction of metal material coating process, coating, etc., can solve the problems of complex heat treatment process, curling burn-through, poor feasibility and other problems, achieve small deformation, accelerated cooling and cooling, thermal influence small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

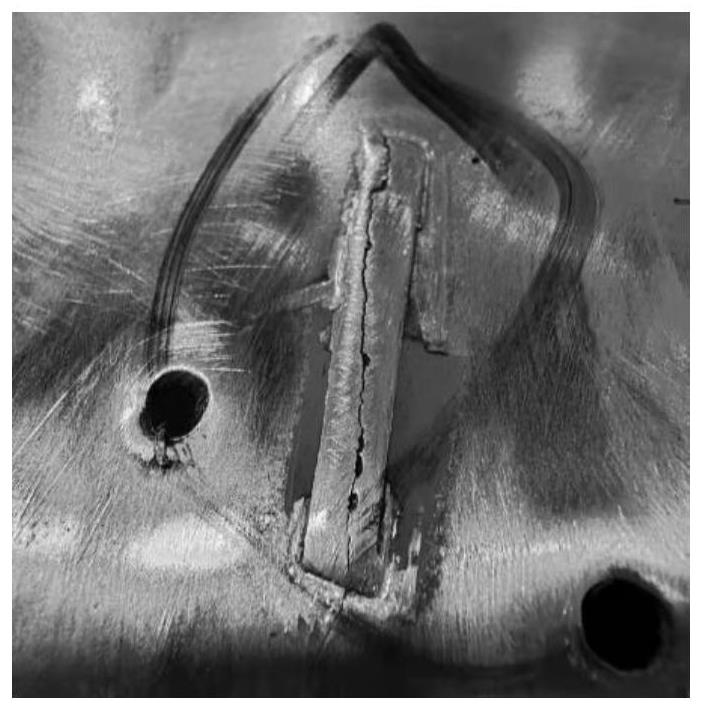

[0057] This embodiment is a method for repairing surface cracks of titanium alloy thin-walled parts. figure 1 , using the combination of laser cladding and DC argon arc welding technology, strictly control the process parameters to ensure the integrity of the matrix structure and the stability of the repair quality, and restore the flatness and smoothness of the repair surface through grinding wheel grinding, combined with non-destructive testing methods to detect cracks , lack of fusion and other defects, the specific steps are as follows:

[0058] Step 1: Pre-weld treatment

[0059] 1.1 Use a grinding wheel to polish the coating and oxide layer on the surface of the titanium alloy skin until the metallic luster is exposed, and find all cracks on the surface of the titanium alloy skin. For cracks that penetrate the wall thickness of the titanium alloy, the titanium alloy where the crack is located should also be The coating and oxide layer on and around the back of the alloy...

Embodiment 2

[0085] This embodiment is a method for repairing surface cracks of titanium alloy thin-walled parts, and the specific steps are as follows:

[0086] Step 1: Pre-weld treatment

[0087] This step is the same as Step 1 in Example 1.

[0088] Step 2: Laser Cladding Repair

[0089] 2.1 Select TC4 titanium alloy powder with a particle size of 75 μm to 125 μm for drying treatment. The drying temperature is 135° C., the drying time is 4 hours, and the vacuum degree is -1 bar.

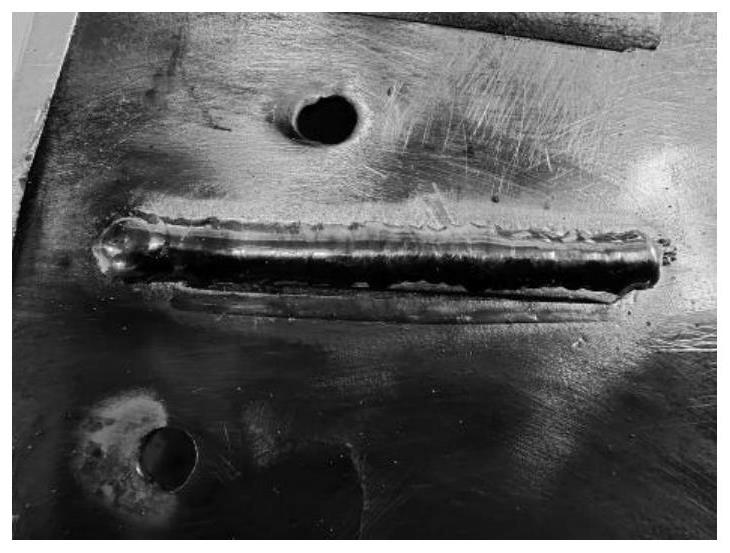

[0090] 2.2 Determine the repair path

[0091] According to the width and depth of the groove opened by the crack, the number of laser cladding passes and layers are set to 7 and 8 layers, respectively, until the surface of the cladding layer is higher than the surface of the titanium alloy skin, reducing the heat input at the same time Ensure sufficient machining allowance.

[0092] 2.3 Laser cladding

[0093] 2.3.1 Preheating before repair:

[0094] In order to reduce the initiation of cracks and ensure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com