Polyurethane material with composite moisturizing coating and application of polyurethane material in field of interventional therapy

A polyurethane material and interventional treatment technology, applied in the field of polyurethane materials, can solve the problems of inability to meet the requirements of low friction, high load and high stability, unsatisfactory molecular brush lubrication effect, poor wettability of polyurethane surface, etc., to maintain long-term lubrication effect, improve the effect of hydration and lubrication, good effect of leaching stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of untreated thermoplastic polyurethane is provided in the present embodiment, as the blank control example of the following examples, the thermoplastic polyurethane is used as the base, and the pretreatment is as follows: cut a 2 × 2 cm sample, respectively with acetone, absolute ethanol Ultrasonic cleaning, followed by soaking in absolute ethanol and deionized water for 12 hours.

[0045] The schemes in the following examples are all grafted on the surface of the polyurethane material provided in this example.

Embodiment 2

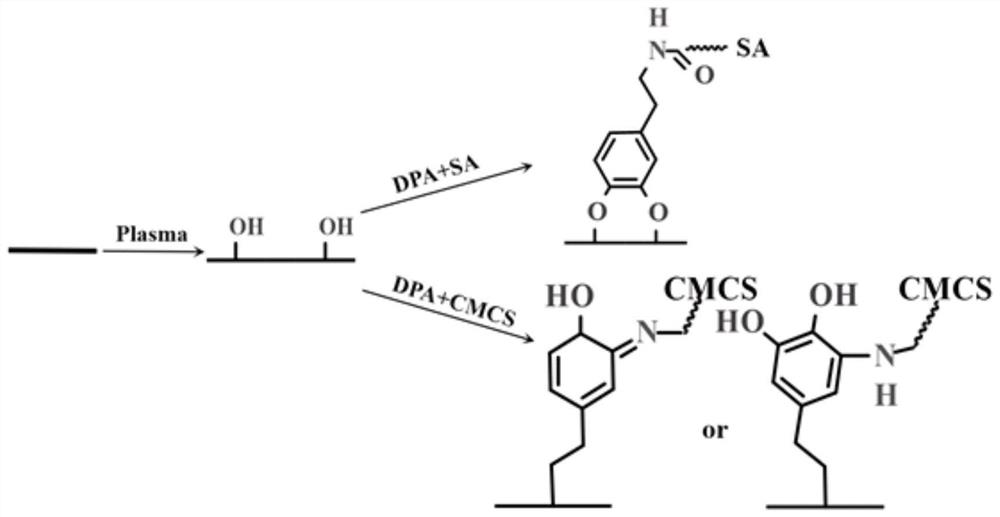

[0047] (1) Under an argon atmosphere, the voltage is 5000V, the pulse frequency is 100Hz, the pulse duty ratio is 30%, and the plasma is treated for 20 minutes to introduce hydroxyl active groups on the surface of the substrate.

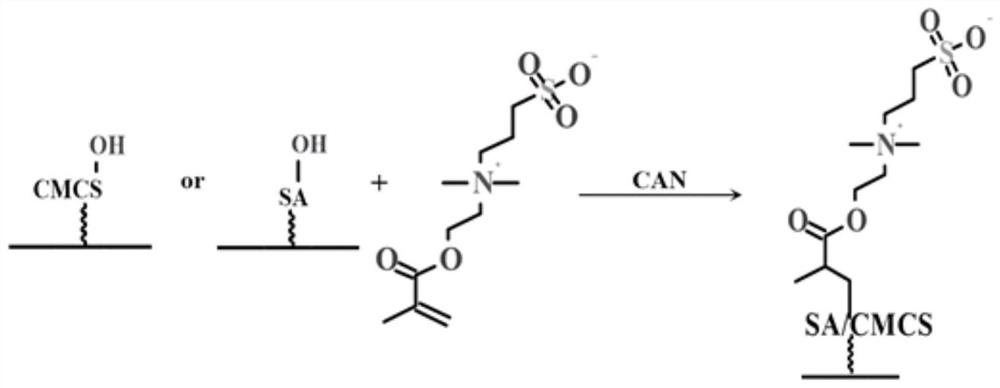

[0048] (2) Measure 80mL water, add 8g SBMA, 0.08g CAN, 0.2g concentrated nitric acid, soak at 55°C for 24 hours, and rinse with deionized water several times.

Embodiment 3

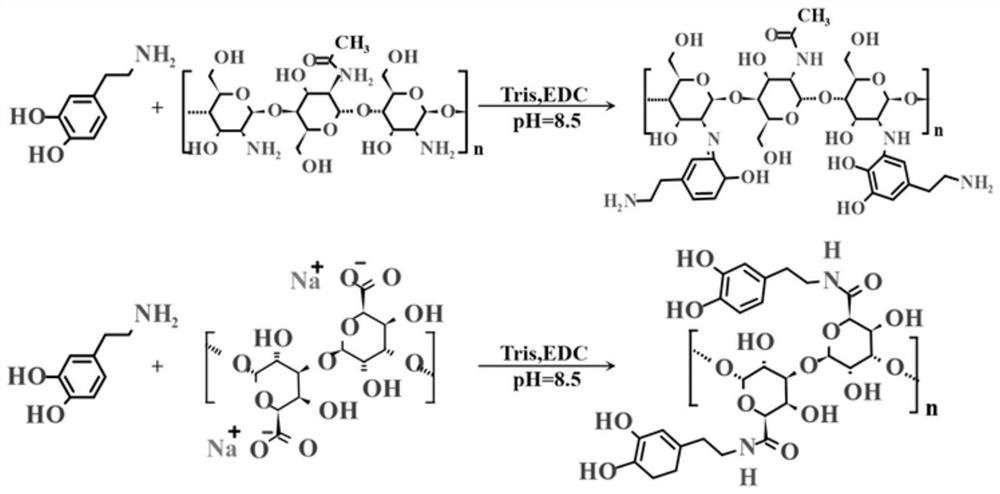

[0050] (1) Measure 80mL of water, 0.097g Tris, hydrochloric acid to adjust the pH to 8.5, 0.19g DPA, 0.4g sodium alginate, 0.14g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), placed at room temperature for 24 hours, then washed in an ultrasonic bath with a large amount of deionized water for 30 seconds, and dried in vacuum. In this step, dopamine undergoes a Michael addition reaction with sodium alginate in an alkaline environment and deposits on substrate surface.

[0051] (2) Measure 80mL water, add 8g SBMA, 0.08g CAN, 0.2g concentrated nitric acid, soak at 55°C for 24 hours, and rinse with deionized water several times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com