Drug-loaded bone repair material as well as preparation method and application thereof

A repair material and bone repair technology, applied in the field of biomedicine, can solve the problems of uncontrollability, increased risk of overgrowth of bone tissue, heterotopic ossification and other complications, and difficulty in accurately regulating the release efficiency of different bioactive factors. Achieve the effect of promoting bone tissue regeneration and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

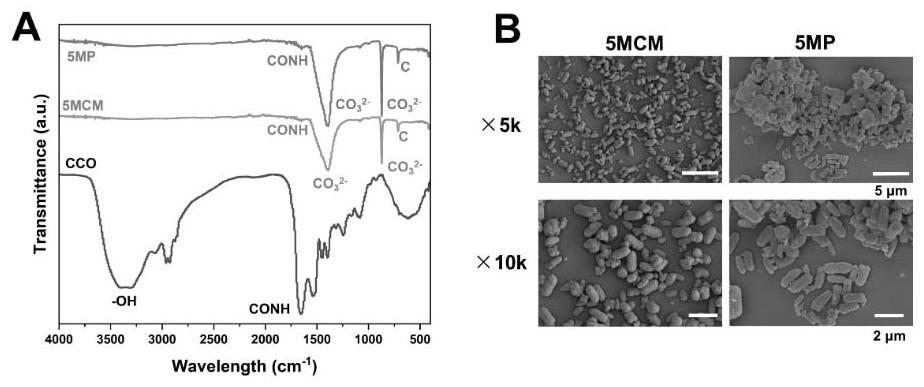

[0056] Example 1: a bone repair material

[0057] The preparation method is as follows:

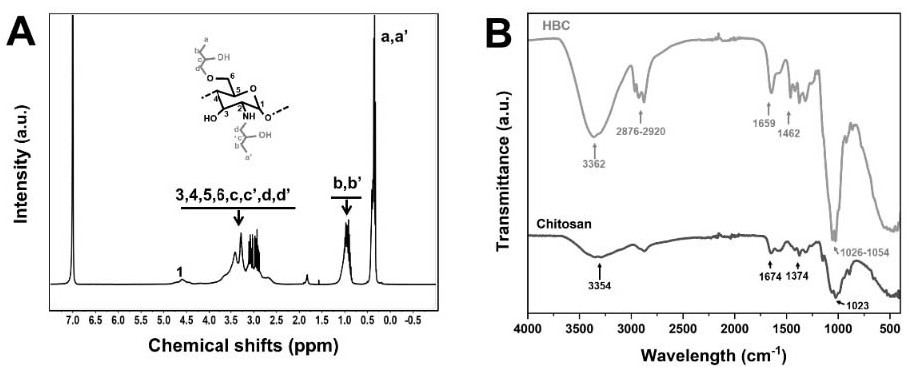

[0058] 1. Preparation of hydroxybutyl chitosan

[0059] The preparation of hydroxybutyl chitosan (HBC) is divided into three steps: alkalization, modification and post-treatment of chitosan:

[0060] (1) Weigh 1g chitosan (sigma, USA) powder and disperse it in 20ml NaOH solution (50%, w / W) for alkalization treatment. Stir at room temperature for 48h, filter and remove the excess alkali solution.

[0061] (2) The alkalized chitosan was added into isopropanol / water (1:1, V / V) solution and dispersed at room temperature for 24 hours until the alkalized chitosan was completely dispersed in isopropanol / water solution. Add 20 ml of 1,2-epoxy butane (Aladdin, China) slowly into the dispersion obtained in the above steps, and place it in a heated magnetic stirrer for reaction at 55 ℃ for 72 hours. After the reaction, cool to room temperature, add 0.1 M HCl solution dropwise to the reaction sol...

Embodiment 2

[0078] Example 2. Detection of physical and chemical properties of bone repair materials

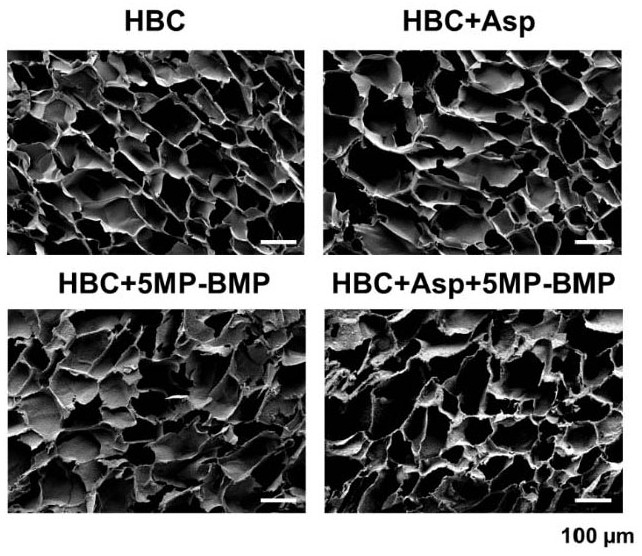

[0079] (1) Morphological observation of bone repair materials

[0080] HBC, HBC + ASP, HBC + 5MP BMP and HBC + ASP + 5MP BMP bone repair materials were freeze-dried with a vacuum freeze dryer. The exposed section of the bone repair materials was cut with a blade and sprayed with gold in vacuum. The section morphology and internal microstructure of the bone repair materials were observed with scanning electron microscope (SEM), and the voltage was 5.0 kV.

[0081] Results such as Figure 3 It is shown that HBC + ASP + 5mp-bmp bone repair material is loose and porous inside, with good morphology, and its pore diameters are 70 ~ 100 μ m. This pore size is conducive to the climbing of cells, the absorption of nutrients and the elimination of metabolic waste. The addition of ASP and 5mp-bmp microspheres had no significant effect on the internal structure of bone repair materials. The internal pore...

Embodiment 3

[0085] Example 3. Detection of stimulation response characteristics and factor release characteristics of bone repair materials

[0086] (1) Detection of temperature sensitive properties of bone repair materials

[0087] The rheological behavior of HBC, HBC + ASP, HBC + 5mp-bmp and HBC + ASP + 5mp-bmp were observed with HAAKE Mars 40 rheometer. The measurement method is as follows: place the colloidal bone repair material on the detection plate with a diameter of 25 mm, set the test distance between the parallel plates as 0.1 mm, the measurement temperature range is 4 ~ 40 ℃, the heating rate is 1 ℃ / min, the fixed strain is 1%, and the frequency is 1 Hz, and record the storage modulus of the bone repair material sample varying with temperature And loss modulus Changes in. During the experiment, silicon oil layer was coated around the bone repair material to prevent the evaporation of water during the heating process.

[0088] Results such as Figure 5 As shown in B, the sol-gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com