PTFE-Al-P energetic structure material and preparation method thereof

A technology of structural materials and PTFE, which is applied in the field of PTFE-Al-P energetic structural materials and its preparation, can solve problems such as hindering applications, incomplete reactions, and limited material diffusion and mass transfer, and achieve good comprehensive energy release characteristics, Improve damage efficiency and prepare efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A PTFE-Al-P energetic structural material, comprising 50-70 wt% of PTFE components, 15-25 wt% of Al components, and 10-30 wt% of P components. In order to improve the kinetic energy and chemical energy damage ability of Al / PTFE, P is added to the PTFE-Al system, so that the active material is cracked into a large number of P-containing fragments under the condition of impact load, and the energy accumulated on the surface of P oxidized in the air makes the temperature When it reaches 40°C, it reaches the ignition point and spontaneously ignites until it is consumed, achieving the secondary arson effect. At the same time, the temperature of P in the combustion process can reach above 1000°C, which can make the unreacted PTFE-Al continue to react at high temperature, improve the reaction efficiency and energy output of the material, and improve the damage efficiency.

[0028] The PTFE adopts the powder with an average particle diameter of 15-25 μm, the Al adopts the powde...

Embodiment 2

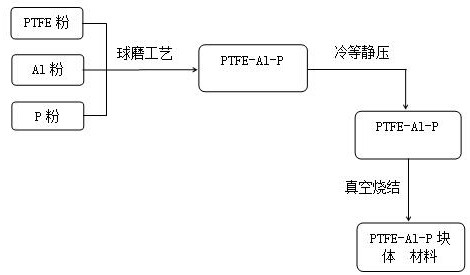

[0030] Such as figure 1 Shown, a kind of preparation method of high-density PTFE-Al-P energetic structure material;

[0031] (1) Ball milling powder mixing: Weigh 66.1g of PTFE powder with an average particle size of 20μm, 23.9g of Al powder with an average particle size of 10μm, 10g of P powder with an average particle size of 30μm, and 200g of cemented carbide grinding balls. The weighed raw material powder and balls are put into the ball mill jar, and then the ball mill jar is fixed on the ball mill for ball milling to obtain energetic powder. The ball milling process parameters are as follows: the ball milling speed is 200r / min, and the ball milling time is 2h to obtain energetic powder. Among them, every 20 minutes of ball milling needs to be stopped for 10 minutes to reduce the temperature of the balls in the ball mill tank.

[0032] (2) Molding: The energetic powder prepared by ball mill mixing is put into a rubber mold, and pressed by cold isostatic pressing to obtai...

Embodiment 3

[0035] A preparation method of high-density PTFE-Al-P energetic structural material;

[0036] (1) Mixed powder by ball milling: Weigh 58.8g of PTFE powder with an average particle size of 20μm, 21.2g of Al powder with an average particle size of 10μm, 20g of P powder with an average particle size of 30μm, and 200g of cemented carbide grinding balls. The weighed raw material powder and balls are put into the ball mill jar, and then the ball mill jar is fixed on the ball mill for ball milling to obtain energetic powder. The ball milling process parameters are as follows: the ball milling speed is 200r / min, and the ball milling time is 2h to obtain energetic powder. Among them, every 20 minutes of ball milling needs to be stopped for 10 minutes to reduce the temperature of the balls in the ball mill tank. The average particle size ratio of the PTFE powder, Al powder, and P powder is 2:1:3 to form graded particles, so that the density of the material system made is higher, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com