Steel-aluminum alloy laser welding method adopting nickel-based high-entropy alloy intermediate layer

A high-entropy alloy and laser welding technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., to reduce stress distribution, reduce thickness, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

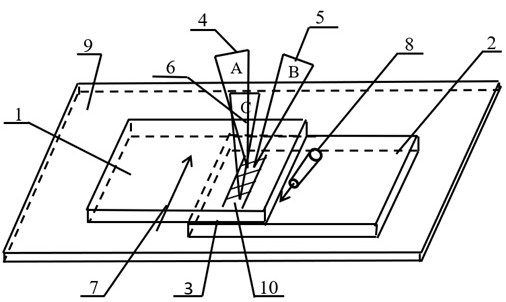

[0036] Aluminum alloy plates and steel plates with a thickness of 2mm are used, and double-beam laser welding of equal-thickness plates is adopted. The material of the middle layer is nickel-based high-entropy alloy metal foil CoTiCuNiSi 0.4 , the thickness is 0.2mm, the specific implementation steps are as follows:

[0037] 1. Polish the steel plate and aluminum alloy plate with sandpaper to remove the oxide film on the surface of the metal plate, then clean it with acetone, and dry it in vacuum for later use. The dried metal plate is fixed on the fixture with a pressure plate according to the overlapping form of steel plate-nickel-based high-entropy alloy metal foil-aluminum alloy plate from top to bottom to ensure that all contact surfaces of the metal plate are in good contact.

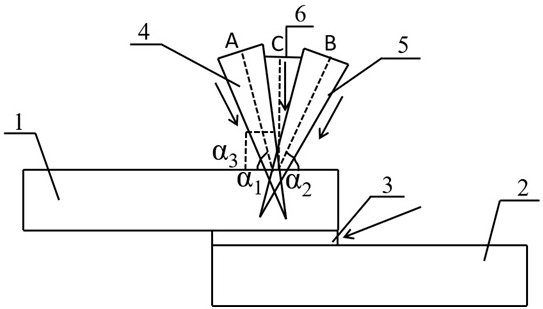

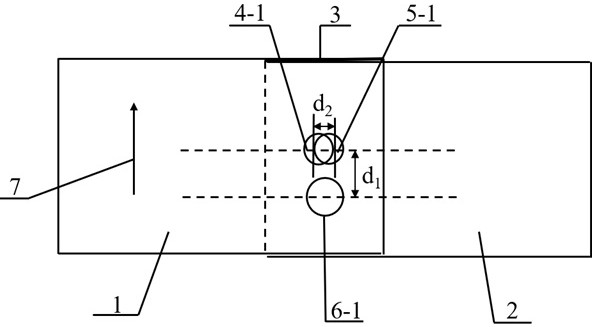

[0038] 2. Set the circular spot positions of laser beams A, B, and C: adjust the circular spot radius R of laser beams A and B 1 =R 2 1mm, adjust the circular spot radius R of the laser beam C ...

Embodiment 2

[0043] The steel plate with a thickness of 4mm and the aluminum alloy plate with a thickness of 2mm are used for double-beam laser welding of non-equal thickness plates. The material of the middle layer is nickel-based high-entropy alloy metal foil CoTiCuNiSi 0.4 , the thickness is 0.4mm, the specific implementation steps are as follows:

[0044] 1. Polish the steel plate and aluminum alloy plate with sandpaper to remove the oxide film on the surface of the metal plate, then clean it with acetone, and dry it in vacuum for later use. The dried metal plate is fixed on the fixture with a pressure plate according to the overlapping form of steel plate-nickel-based high-entropy alloy metal foil-aluminum alloy plate from top to bottom to ensure that all contact surfaces of the metal plate are in good contact.

[0045] 2. Set the positions of the two circular spots of laser beams A, B, and C: R 1 =R 2 1mm, the circular spot radius R of the laser beam C 3 1.5mm. The two circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com