Method for continuous hydrogenation synthesis of 1, 3-dimethyl-2-imidazole based on serial microreactors

A technology of microreactor and dimethyl, which is applied in the field of chemical reaction, can solve the problems of low production efficiency, low product purity, high production cost, etc., and achieve the effects of prolonging service life, high mass transfer efficiency and strong heat transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

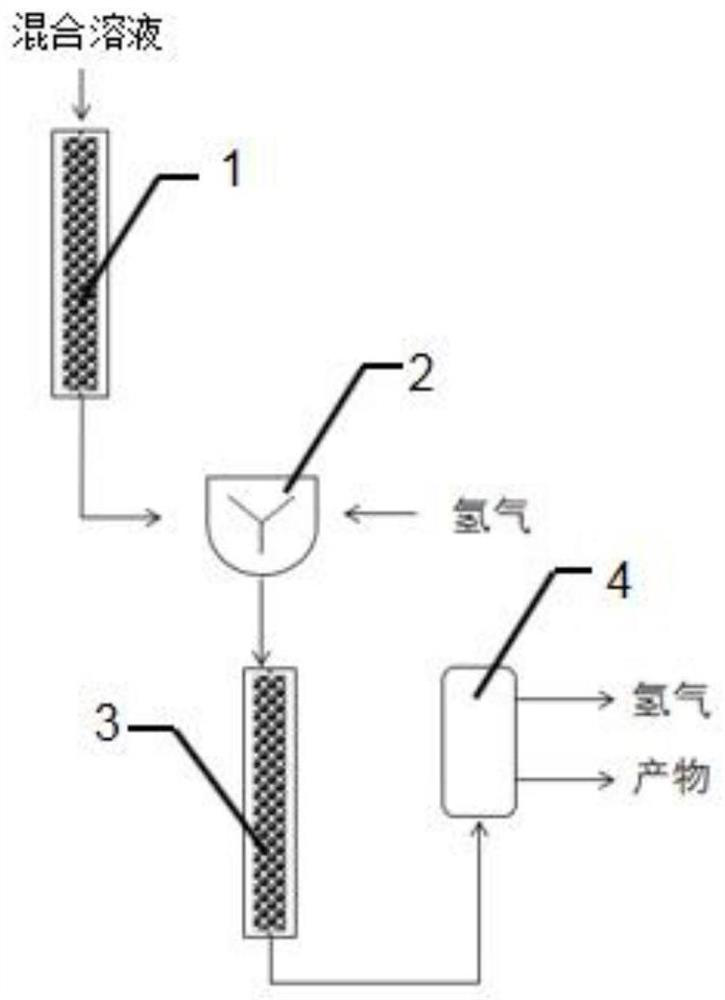

[0028] A method for continuously hydrogenating 1,3-dimethyl 2-imidazole based on series microreactors, the steps are as follows:

[0029] (1) Formaldehyde and 2-imidazolidinone are mixed according to the molar ratio of 2.5:1, dissolved in a solvent with a mass ratio of methanol to water of 1:2, and prepared into a methanol-water solution of 2-imidazolidinone with a concentration of 5 wt%. ;

[0030] (2) The methanol-water solution of 2-imidazolidinone in step (1) is passed through the micro-packed bed 1 with sulfonic acid group ion exchange resin, reacted for 5min at 70°C under the condition of a pressure of 3.0MPa, and carried out non- Homogeneous hydrogenation reduction reaction to prepare imine intermediate solution;

[0031] (3) The imine intermediate solution prepared in step (2) is mixed with hydrogen at the inlet micro-mixer according to a molar ratio of 2.5:1 to form a gas-liquid mixed fluid;

[0032] (4) The gas-liquid mixed fluid obtained in step (3) is passed thro...

Embodiment 2

[0035] A method for continuously hydrogenating 1,3-dimethyl 2-imidazole based on series microreactors, the steps are as follows:

[0036] (1) Formaldehyde and 2-imidazolidinone are mixed according to the molar ratio of 3.2:1, dissolved in a solvent with a mass ratio of methanol to water of 1:5, and prepared into a methanol-water solution of 2-imidazolidinone with a concentration of 10 wt%. ;

[0037] (2) The methanol-water solution of 2-imidazolidinone in step (1) is passed through the micro-packed bed 1 with carboxylic acid-based ion exchange resin, and reacted for 10 minutes at 80 ° C under the condition of 3.5 MPa, and carried out non-toxic Homogeneous hydrogenation reduction reaction to prepare imine intermediate solution;

[0038] (3) The imine intermediate solution prepared in step (2) is mixed with hydrogen in the inlet micro-mixer according to a molar ratio of 3:1 to form a gas-liquid mixed fluid;

[0039] (4) The gas-liquid mixed fluid obtained in step (3) is passed...

Embodiment 3

[0042] A method for continuously hydrogenating 1,3-dimethyl 2-imidazole based on series microreactors, the steps are as follows:

[0043] (1) Formaldehyde and 2-imidazolidinone are mixed according to the molar ratio of 2.5:1, dissolved in a solvent with a mass ratio of methanol to water of 1:10, and prepared into a methanol-water solution of 2-imidazolidinone with a concentration of 5 wt%. ;

[0044] (2) the methanol-water solution of the 2-imidazolidinone of step (1) is passed through packing with solid acid catalyst H 2 SO 4 The micro-packed bed 1 of / C reacted for 5 minutes at 80°C and a pressure of 3.0 MPa, and carried out a heterogeneous hydrogenation reduction reaction to prepare an imine intermediate solution;

[0045] (3) The imine intermediate solution prepared in step (2) is mixed with hydrogen in the inlet micro-mixer according to a molar ratio of 4:1 to form a gas-liquid mixed fluid;

[0046](4) The gas-liquid mixed fluid obtained in step (3) is passed through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com