Segmental assembly type pier with cascade performance and construction method thereof

A prefabricated and segmented technology, applied in the direction of erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of difficult replacement, waste of materials, inconvenient large-scale application of projects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

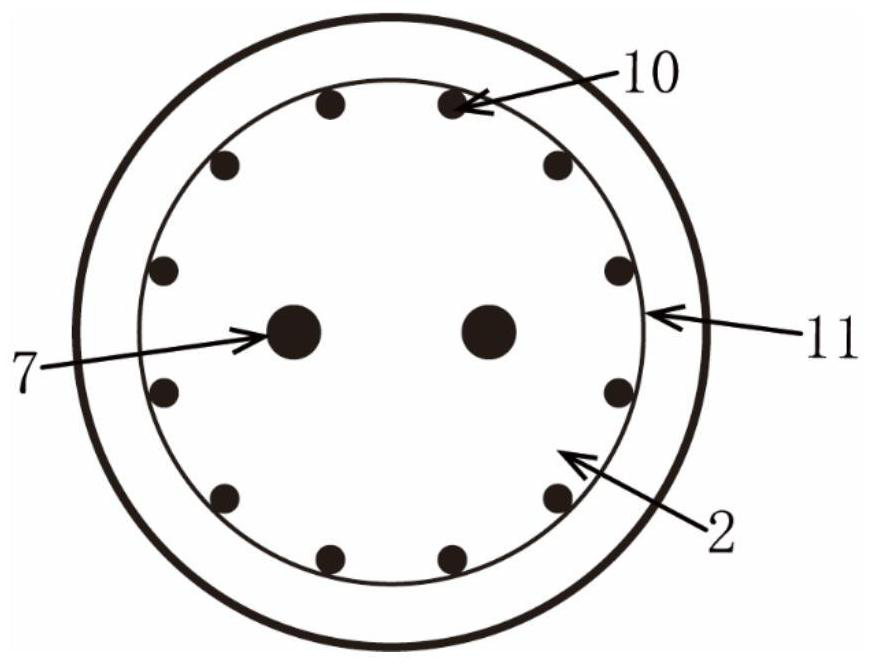

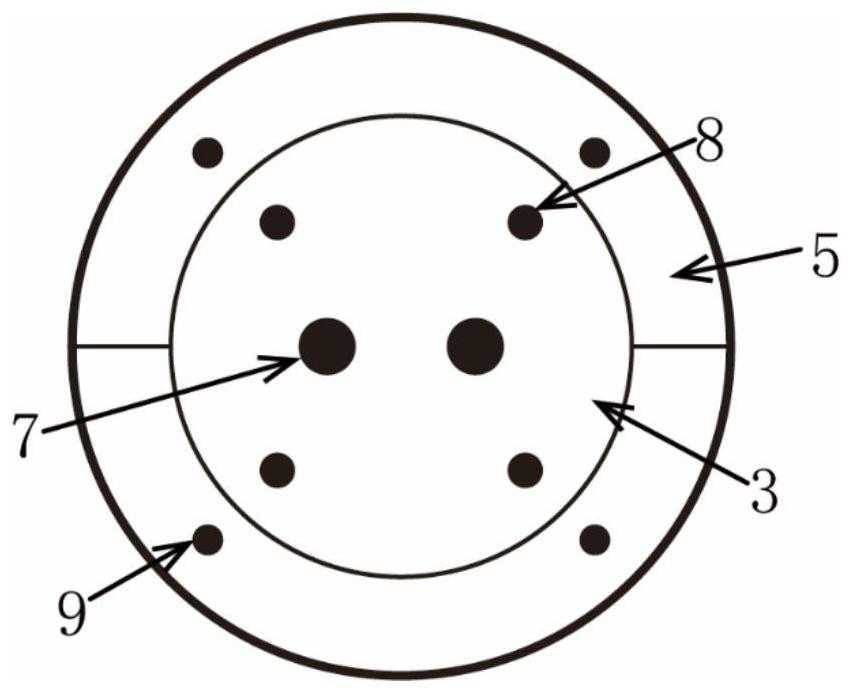

[0041] combined with Figure 1-4 To illustrate the specific implementation, for the arrangement of energy-dissipating steel bars in each section of the pier, combined with the attached figure 2 - Sectional diagram of the pier section, in the section A-A of the pier section, there are several ordinary longitudinal bars and spiral stirrups, no energy-dissipating steel bars, and unbonded prestressed tendons passing through the section; in the section B-B section at the bottom of the pier In the center, the outer replaceable RC segment ring is equipped with multiple ordinary energy-dissipating steel bars, and the inner UHPC segment is equipped with multiple high-strength energy-dissipating steel bars on the left and right sides;

[0042] For the connection between the inner UHPC segment and the outer replaceable RC segment ring, a steel ferrule is used to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com