High-speed processing screw tap

A kind of screw tapping, high-speed technology, applied in metal processing equipment, manufacturing tools, thread cutting tools, etc., can solve the problems of screw tapping, the shape damage of screw tapping cutting edge, etc., to reduce the load, high speed and smooth high-precision internal thread processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

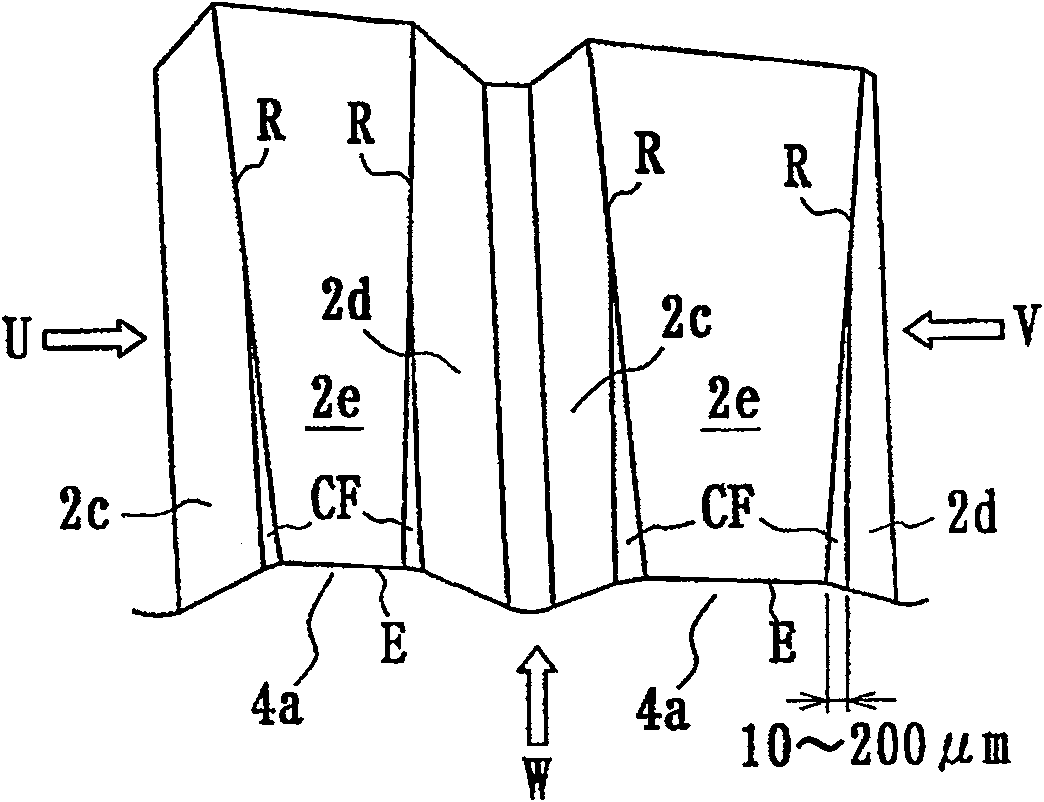

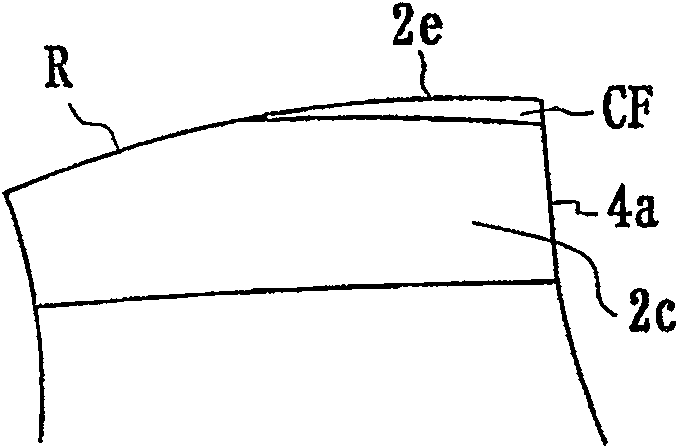

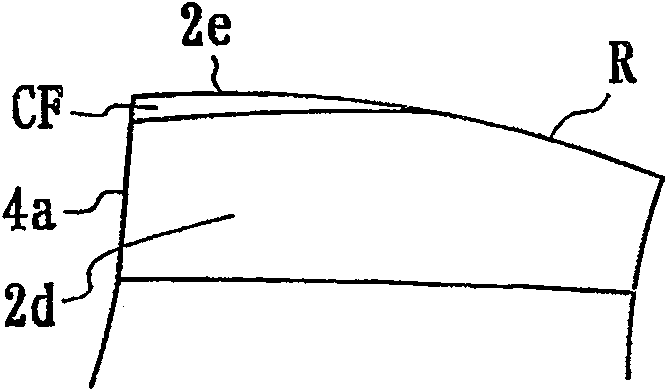

[0031] Embodiments of the present invention will be described in detail below with reference to the drawings through examples. here, Figure 1a , Figure 1b , Figure 1c , Figure 1d In Fig. 2, it shows a side view after enlarging part A in an embodiment of the screw tap for high-speed machining of the present invention and showing along the groove, and a side view viewed from the directions of arrows U, V, and W in the figure, and Figure 2a , Figure 2b The side view and the front view of the present invention are represented in the figure; Figure 3a , Figure 3b , Figure 3c In the explanatory diagram showing the formation procedure of the chamfered portion along the tapped ridge line in the above-mentioned embodiment, the same symbols are used for the same parts as those in the previous example.

[0032] That is, in the screw tap 1 for high-speed machining in this embodiment, as shown in FIG. The cutting edge of part 2 is used to cut and process the internal threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com