A kind of marine microbial fouling laser cleaning method for decontamination and antifouling

A marine microorganism and laser cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as uncontrollable damage to substrates, pollution of the marine environment, poor effects, etc., to achieve accessibility and solve environmental pollution. and waste disposal issues, the effect of good accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

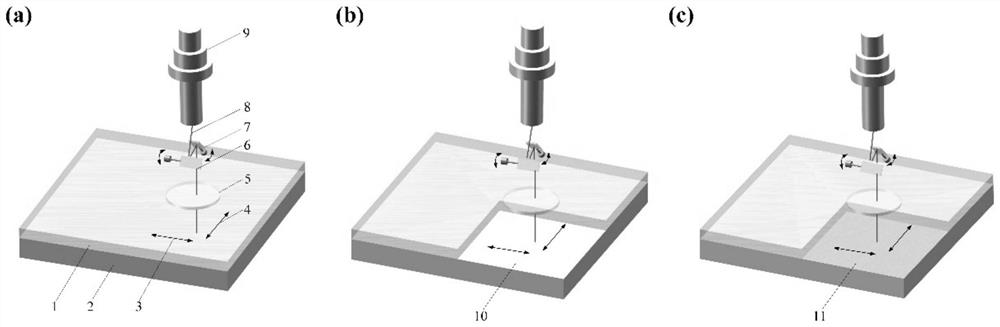

[0029] Specific implementation mode one: a kind of marine microbial fouling laser cleaning decontamination antifouling method of the present embodiment, it is carried out according to the following steps:

[0030] 1. Place the laser cleaning head above the marine microbial fouling surface to be cleaned at a vertical angle or an inclined angle, and keep the distance between the surface to be cleaned and the field lens at 170-190mm;

[0031] 2. Laser removal of marine microorganisms:

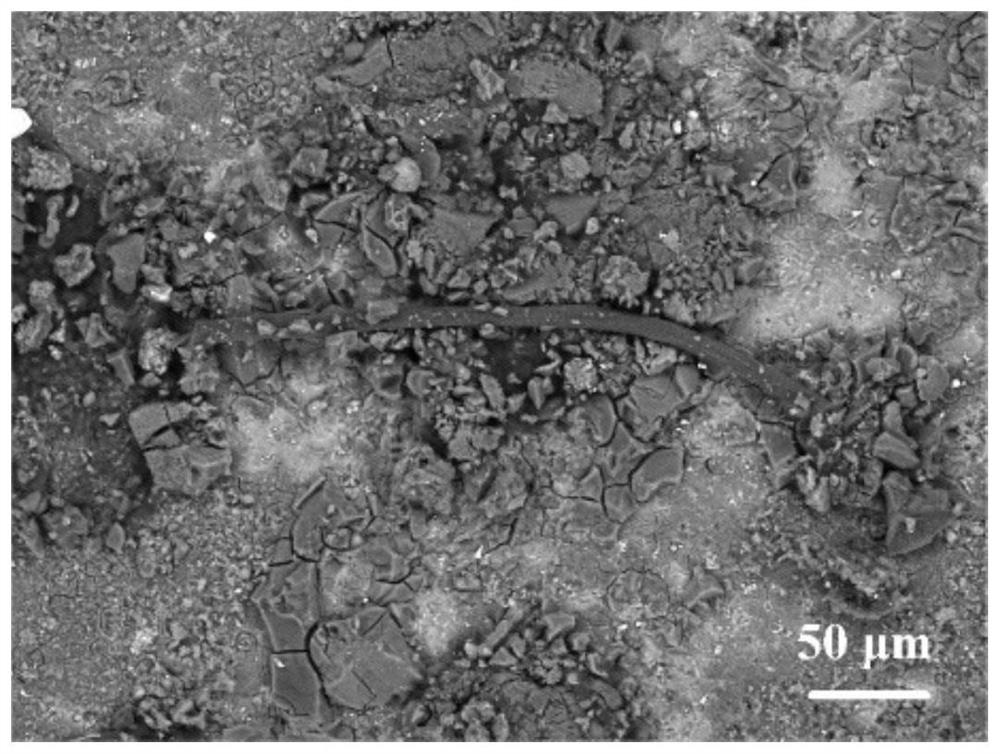

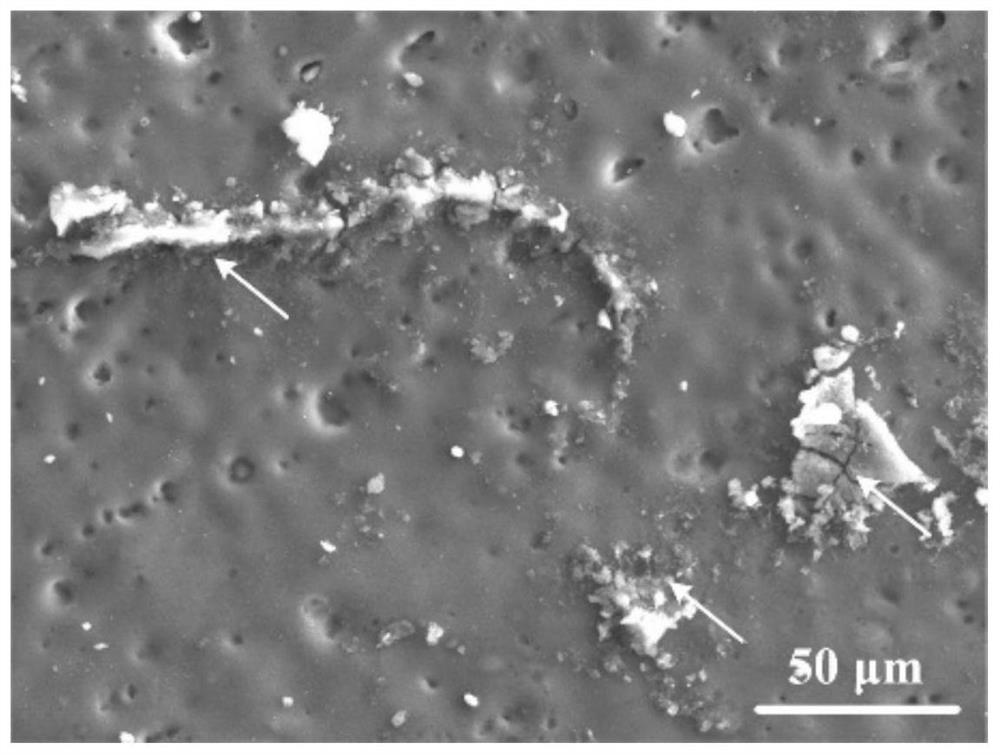

[0032] Set laser parameters: laser power is 200-400W, pulse width is 30ns-100ns; pulse frequency is 5-100kHz, single pulse energy is 10-200mJ, line-by-line overlapping rate is 60%-90%; laser scanning speed is ≤5000mm / s, the laser spot size is 50-1000μm; according to the laser parameters set above, the laser is used to scan the marine microbial fouling surface to be cleaned layer by layer to remove marine microorganisms;

[0033] 3. Acquisition of anti-fouling substrate surface:

[0034] Scannin...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, during the layer-by-layer scanning of the marine microbial fouling surface to be cleaned, the thickness of the marine microbial fouling layer removed by each layer of scanning is 20 μm-65 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment is different from Embodiment 1 in that: the shape of the scanning area is square, and the size is <300mm×300mm. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com