Control method for inclusions in high-titanium steel, high-titanium steel and preparation method of high-titanium steel

A control method and inclusion technology, applied in the field of iron and steel smelting, can solve the problems of effective removal of unfavorable titanium-containing large inclusions, easy accumulation of large inclusions, limited refining time, etc., to avoid nozzle nodules, improve yield, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

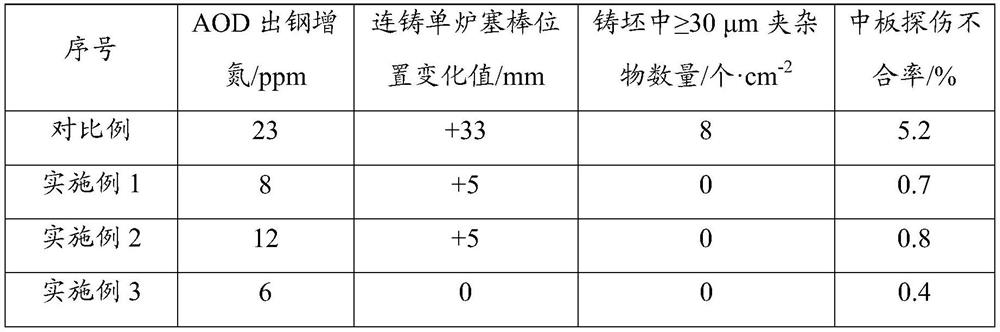

Examples

Embodiment 1

[0061] ⅠAfter the blowing of AOD, silicon-aluminum composite deoxidation is used first, and the Al content is controlled at 0.005wt%;

[0062] Ⅱ Dump the furnace body, remove more than 90% of the slag, and keep the bottom blowing argon protection during the process;

[0063] ⅢAdd 3kg of aluminum shot per ton of steel, 10kg of lime per ton of steel, 8kg of fluorite per ton of steel, and the flow rate of bottom blowing argon is 0.4Nm per ton of steel 3 / min stirring for 5min;

[0064] IVAOD adds titanium alloy block for titanium alloying. The composition of titanium alloy block is: Ti: 92%, Al: 7.8%, N: ≤0.01%, O: ≤0.01%, and the rest are unavoidable impurities; after titanium alloying, continue to use Bottom blowing argon gas flow rate is 0.4Nm per ton of steel 3 / min Stir for 3min;

[0065] Ⅴ During the tapping process, AOD bottom blowing argon protection is maintained, the tapping speed is controlled at 3t / s, and attention is paid to keep the slag covering most of the molt...

Embodiment 2

[0069] ⅠAfter the blowing of AOD, silicon-aluminum composite deoxidation is used first, and the Al content is controlled at 0.015wt%;

[0070] Ⅱ Dump the furnace body, remove more than 90% of the slag, and keep the bottom blowing argon protection during the process;

[0071] ⅢAdd 4kg of aluminum shot per ton of steel, 13kg of lime per ton of steel, 7kg of fluorite per ton of steel, and the flow rate of bottom blowing argon is 0.6Nm per ton of steel 3 / min stirring 6min;

[0072] IVAOD adds titanium alloy block for titanium alloying. The composition of titanium alloy block is: Ti: 92%, Al: 7.8%, N: ≤0.01%, O: ≤0.01%, and the rest are unavoidable impurities; after titanium alloying, continue to use Bottom blowing argon gas flow is 0.6Nm per ton of steel 3 / min stirring for 5min;

[0073] Ⅴ During the tapping process, AOD bottom blowing argon protection is maintained, the tapping speed is controlled according to 6t / s, and attention is paid to keep the slag covering most of the...

Embodiment 3

[0077] Ⅰ After the blowing of AOD, silicon-aluminum composite deoxidation is used first, and the Al content is controlled at 0.008wt%;

[0078] Ⅱ Dump the furnace body, remove more than 90% of the slag, and keep the bottom blowing argon protection during the process;

[0079] Ⅲ Add 5kg of aluminum shot per ton of steel, 15kg of lime per ton of steel, 5kg of fluorite per ton of steel, and the flow rate of bottom blowing argon is 0.6Nm per ton of steel 3 / min stirring 8min;

[0080] IVAOD adds titanium alloy block for titanium alloying. The addition amount is calculated according to the yield of 65-80%. The composition of titanium alloy block is: Ti: 94%, Al: 5.9%, N: ≤0.01%, O: ≤0.01%, The rest are unavoidable impurities; after titanium alloying, continue to use bottom blowing argon flow rate of 0.6Nm per ton of steel 3 / min stirring for 5min;

[0081] Ⅴ During the tapping process, AOD bottom blowing argon protection is maintained, the tapping speed is controlled according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com