Sewage in-situ treatment and recycling method for mobile toilet

An in-situ treatment, mobile toilet technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. The water quality is not up to the standard, to achieve the effect of speeding up the biochemical reaction, improving the quality of the produced water, and improving the sanitation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

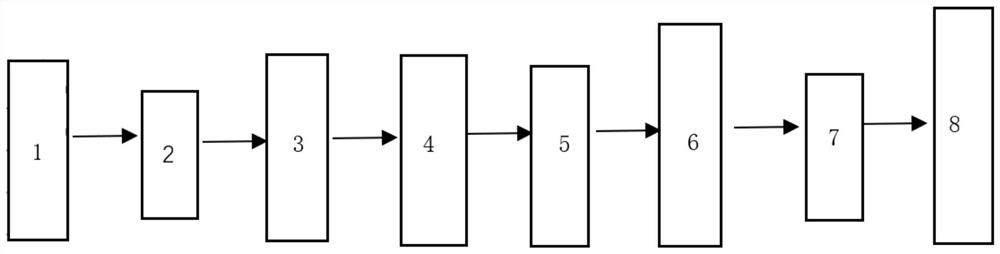

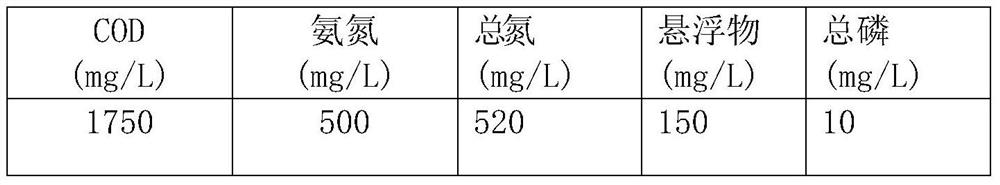

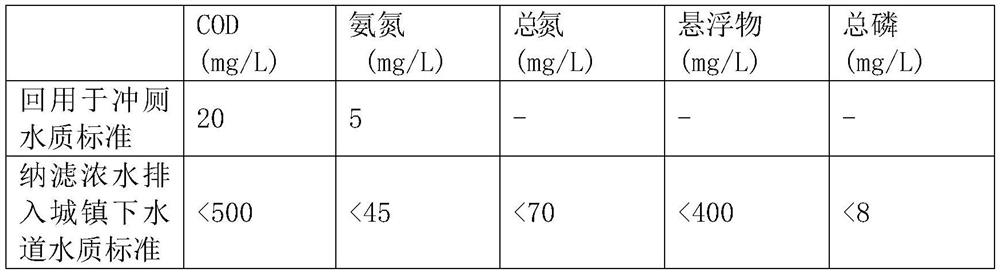

[0028] The specific implementation process of a sewage in-situ treatment and reuse method for mobile toilets of the present invention is as follows: use pipelines to sequentially connect adjustment tanks, water pumps, screw stackers, anoxic tanks, aerobic tanks, tubular ultrafiltration, nano Sewage in-situ treatment and reuse system composed of filtration and reuse tanks. The specific process is as follows: the fecal sewage produced by the mobile toilet first enters the regulating tank, which is equipped with a stirring paddle to achieve uniform mixing of the fecal sewage, and the hydraulic retention time is 2.5 hours; the water from the regulating tank is pumped into the screw stacker for solid-liquid separation , the water pump has self-priming function and stirring function; after the screw stacker concentrates and dehydrates the solid, the moisture content of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com