Sand control flowback process after shale gas horizontal well fracturing

A technology for horizontal wells and shale gas, which is applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc. sand risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

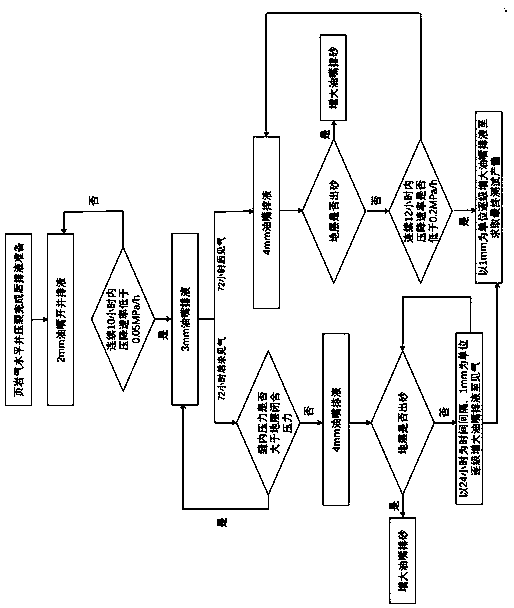

[0034] As a preferred embodiment of the present invention, it discloses a sand control flowback process after fracturing of a shale gas horizontal well, the steps of which are as follows:

[0035] (1) Use 2mm choke nozzles to open wells and drain liquids in shale gas horizontal wells that have been fractured, and continuously record the changes in wellhead pressure. If the pressure drop rate is lower than 0.05MPa / h for 10 consecutive hours, increase the choke nozzle to 3mm Drainage, the sum of the draining time of 2mm and 3mm nozzles shall not be less than 72 hours;

[0036] (2) After 72 hours of liquid drainage, take the following two measures according to whether gas is seen:

[0037] If no gas is found, calculate the pressure in the bottom hole fracture according to the wellhead pressure. If the pressure in the fracture is greater than the formation closure pressure in this area, continue to use the 3mm nozzle to drain until the formation is closed; if the pressure in the f...

Embodiment 2

[0040] On the basis of Example 1, in the step (2), the specific method for judging whether the formation produces sand and adjusting the working system after sand production is as follows:

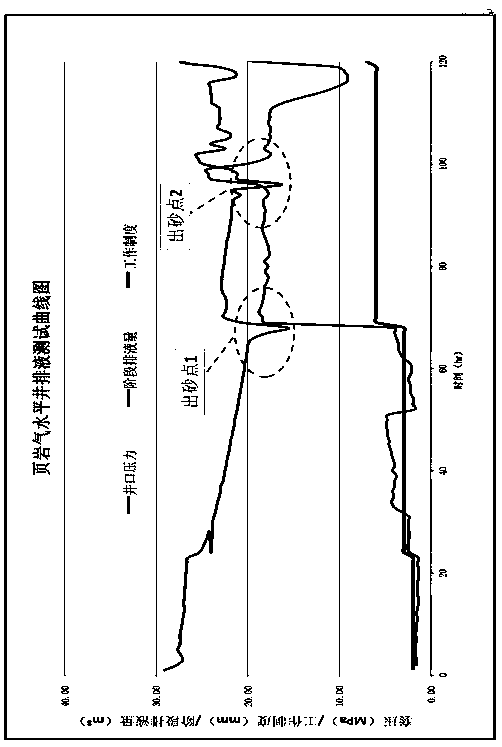

[0041] For normal flowback wells, the wellhead pressure changes regularly with the adjustment of the choke working system. If the wellhead pressure responds abnormally, through the analysis of the pressure drop rate, it can be directly judged whether the formation has sand or not;

[0042] After confirming the sand production in the formation, calculate the wellbore lifting efficiency under the current choke system in real time according to the wellbore flow state, and then adjust the choke according to the degree of sand production, and use the formation energy to carry sand until the wellhead pressure returns to normal and no sand returns from the surface process. Adjust to the original nozzle working system and continue to discharge liquid.

Embodiment approach

[0044] As the best implementation mode of the present invention, it comprises the following steps:

[0045] a. Use 2mm choke nozzles to open wells and drain liquids in shale gas horizontal wells that have been fractured, and continuously record the changes in wellhead pressure. If the pressure drop rate is lower than 0.05MPa / h for 10 consecutive hours, then increase to 3mm choke nozzles. Liquid, the sum of the draining time of 2mm and 3mm nozzles is not less than 72 hours;

[0046]b. After 72 hours of liquid drainage, take the following two measures according to whether gas is seen:

[0047] ① If no gas is found, calculate the pressure in the bottom hole fracture according to the wellhead pressure. If the pressure in the fracture is greater than the formation closure pressure in this area, continue to use the 3mm nozzle to drain until the formation is closed; if the pressure in the fracture is lower than the formation closure pressure in this area, At this time, the stratum i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com