Proton exchange membrane fuel cell for testing

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as poor sealing effect, uneven gas dispersion, and reduced battery reaction efficiency, and achieve convenient disassembly, promote uniform distribution, and solve problems. The effect of battery drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

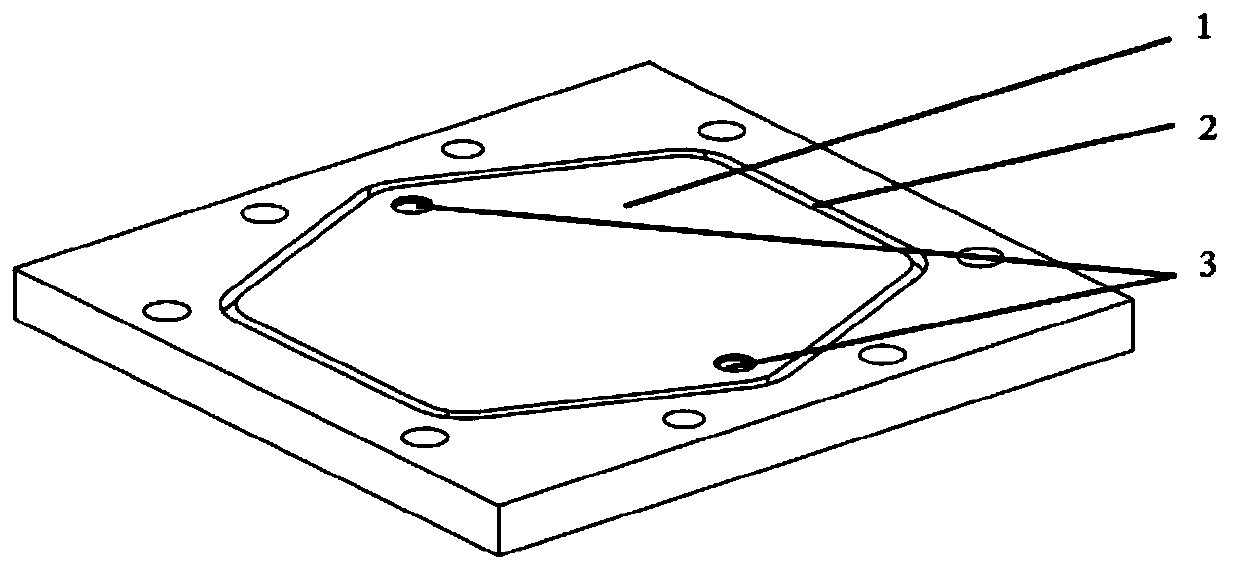

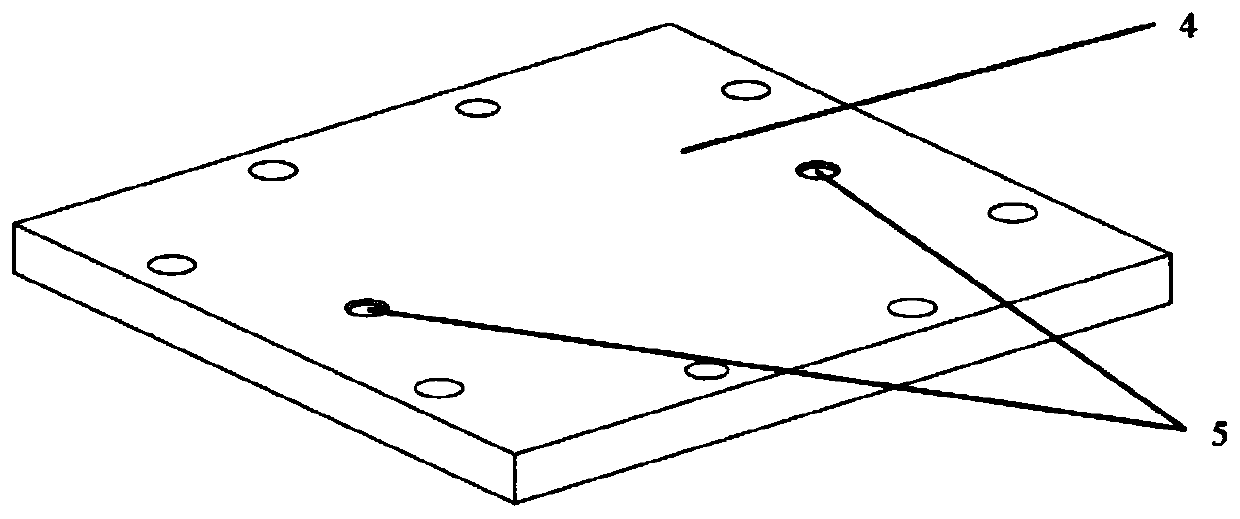

[0046] The size of the test proton exchange membrane fuel cell is related to the effective area of the test cell. In this embodiment, the effective area is 50×50mm 2 battery for testing. Such as figure 1 and 2 As shown, the two ends of the battery are an upper end plate 1 and a lower end plate 4 with the same shape and size, the size is 160mm×160mm, and the thickness is 20mm. The upper end plate 1 is provided with an inlet and outlet 3 for an oxidant gas, and a through threaded hole with a diameter of Φ5mm, and the oxidant gas is oxygen. The lower end plate 4 is provided with a fuel gas inlet and outlet 5, and a through threaded hole with a size of Φ5-8mm, and the fuel gas is hydrogen. The upper end plate 1 and the lower end plate 4 are provided with sealing grooves 2 filled with high-elastic silicone sealing rings.

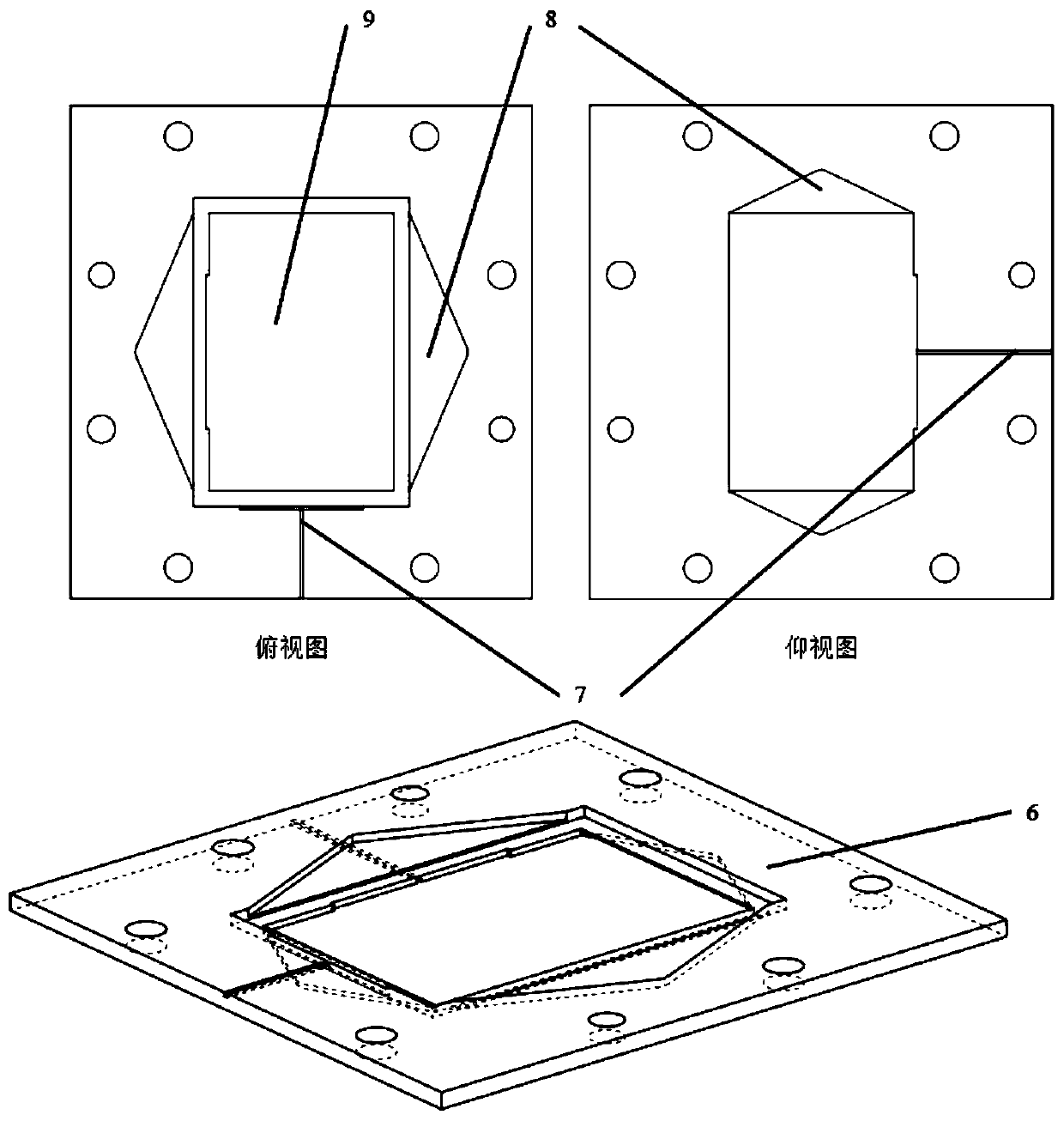

[0047] Such as image 3 As shown, the separator 6 is sandwiched between the upper end plate 1 and the lower end plate 4, with a size of 160mm×160mm and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com