Fine-grain aluminum alloy and preparation method and application thereof

An aluminum alloy and fine-grain technology, applied in the field of aluminum alloys, can solve the problems of reducing the deformation properties, poor tensile properties and deformation properties of aluminum alloys, and declining mechanical properties of aluminum alloys, and achieve excellent extrusion properties and excellent tensile properties. , The effect of excellent thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] In this embodiment, a fine-grained aluminum alloy is prepared, and the specific process is as follows:

[0114] S1. Casting:

[0115]S1a. Melting aluminum ingots at 780-800°C (the set temperature is 790°C, but the actual temperature during the process may fluctuate within the range of 780-800°C);

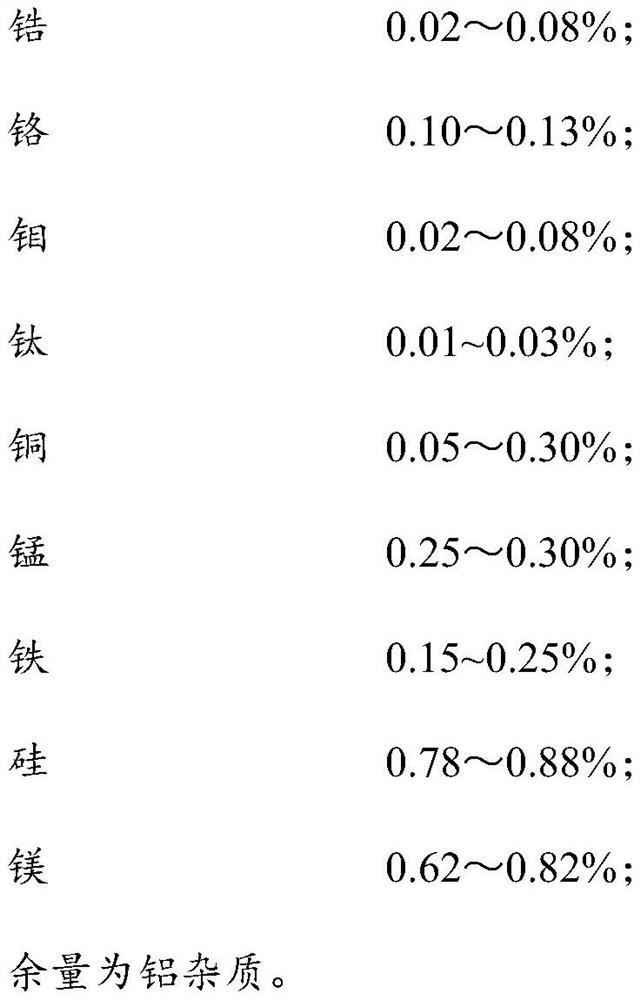

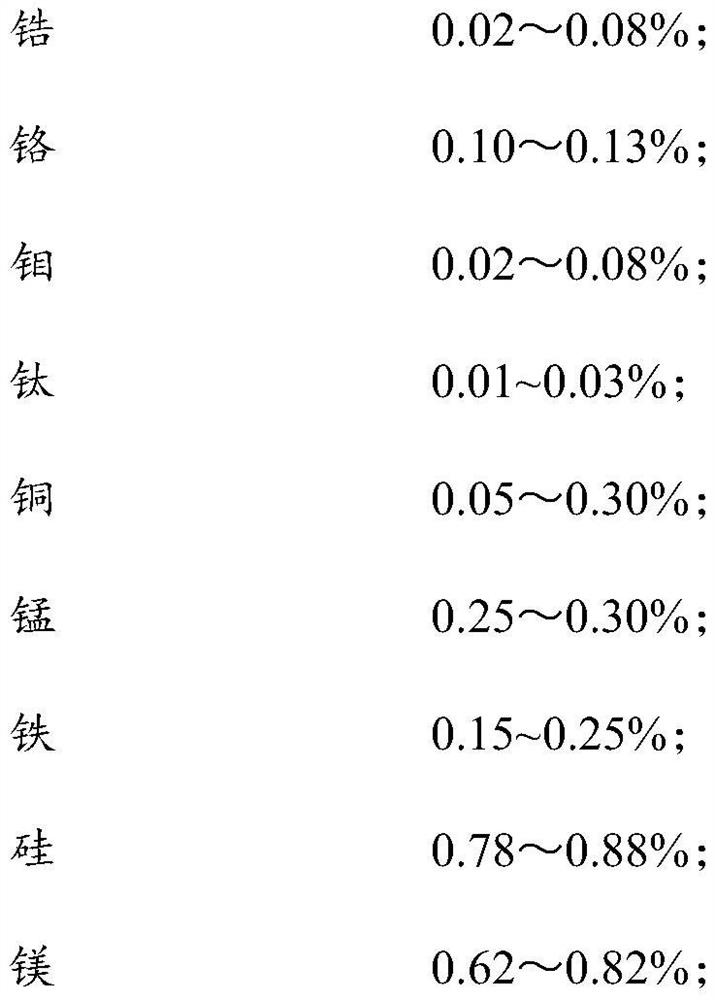

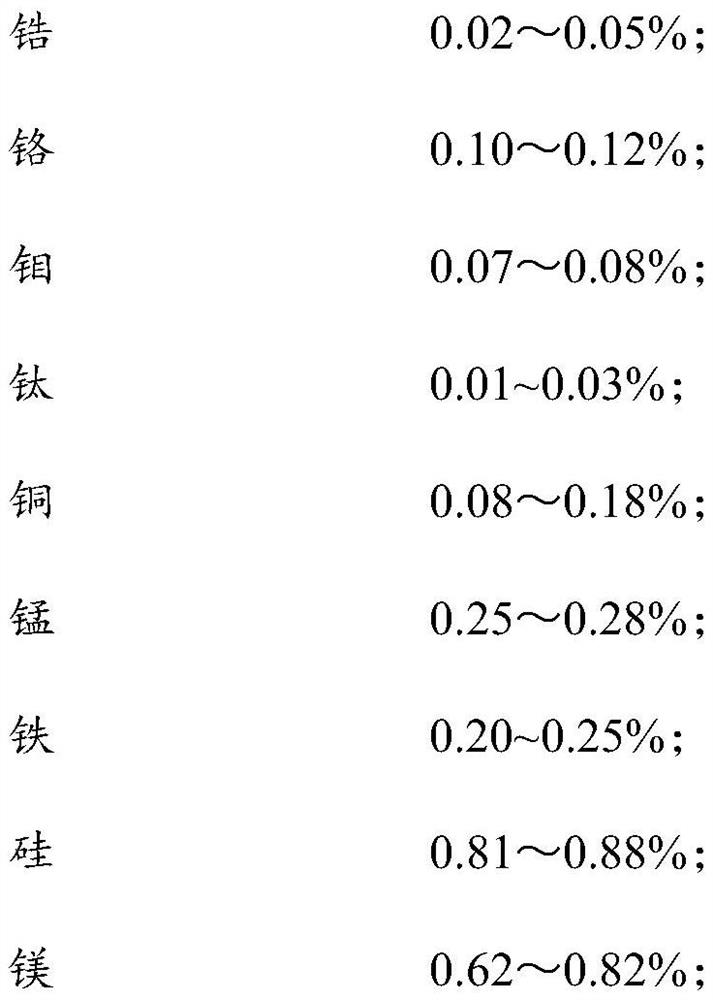

[0116] S1b. According to the ratio in Table 1, add Al-Si master alloy, magnesium ingot, Al-Mo master alloy, Al-Zr master alloy, red copper, Mn agent, Cr agent and Fe agent to the melt obtained in step S1a;

[0117] S1c. According to the ratio of refining agent: melt = 2kg: 1 ton, add refining agent to the melt obtained in step S1b for refining; the refining temperature is 730°C, and the refining time is 30 minutes. Pass argon gas (purity ≥ 99.999%) into the body for stirring, exhaust, and then slag removal;

[0118] S1d. The composition of the melt in the adjustment step S1c meets the requirements of Table 1 (except titanium), and then adds an Al-Ti master alloy to control ...

Embodiment 2

[0131] In this embodiment, a fine-grained aluminum alloy is prepared, and the specific process is as follows:

[0132] S1. Casting:

[0133] S1a. melting the aluminum ingot at 780-800°C (same as Example 1);

[0134] S1b. According to the ratio in Table 1, add Al-Si master alloy, magnesium ingot, Al-Mo master alloy, Al-Zr master alloy, red copper, Mn agent, Cr agent and Fe agent to the melt obtained in step S1a;

[0135] S1c. According to the ratio of refining agent: melt = 2kg: 1 ton, add refining agent to the melt obtained in step S1b for refining; the refining temperature is 730°C, and the refining time is 30 minutes. Pass argon gas (purity ≥ 99.999%) into the body for stirring, exhaust, and then slag removal;

[0136] S1d. The composition of the melt in the adjustment step S1c meets the requirements of Table 1 (except titanium), and then adds an Al-Ti master alloy to control the Ti content to 0.015%;

[0137] S1e. Within 10 minutes after the end of step S1d, cast the mel...

Embodiment 3

[0149] In this embodiment, a fine-grained aluminum alloy is prepared, and the specific process is as follows:

[0150] S1. Casting:

[0151] S1a. melting the aluminum ingot at 780-800°C (same as Example 1);

[0152] S1b. According to the ratio in Table 1, add Al-Si master alloy, magnesium ingot, Al-Mo master alloy, Al-Zr master alloy, red copper, Mn agent, Cr agent and Fe agent to the melt obtained in step S1a;

[0153] S1c. According to the ratio of refining agent: melt = 2kg: 1 ton, add refining agent to the melt obtained in step S1b for refining; the refining temperature is 730°C, and the refining time is 30 minutes. Pass argon gas (purity ≥ 99.999%) into the body for stirring, exhaust, and then slag removal;

[0154] S1d. The composition of the melt in the adjustment step S1c meets the requirements of Table 1 (except titanium), and then adds an Al-Ti master alloy to control the Ti content to 0.015%;

[0155] S1e. Within 10 minutes after the end of step S1d, cast the mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com