A kind of preparation method of high-purity methyl silicone oil

A methylsilicone oil, high-purity technology, applied in the field of preparation of high-purity methylsilicone oil, can solve problems such as affecting the polymerization reaction of methylsilicone oil, reduction of catalyst active sites, malodorous odor, etc., and achieves excellent metal ion adsorption performance, excellent The effect of denitrification performance and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

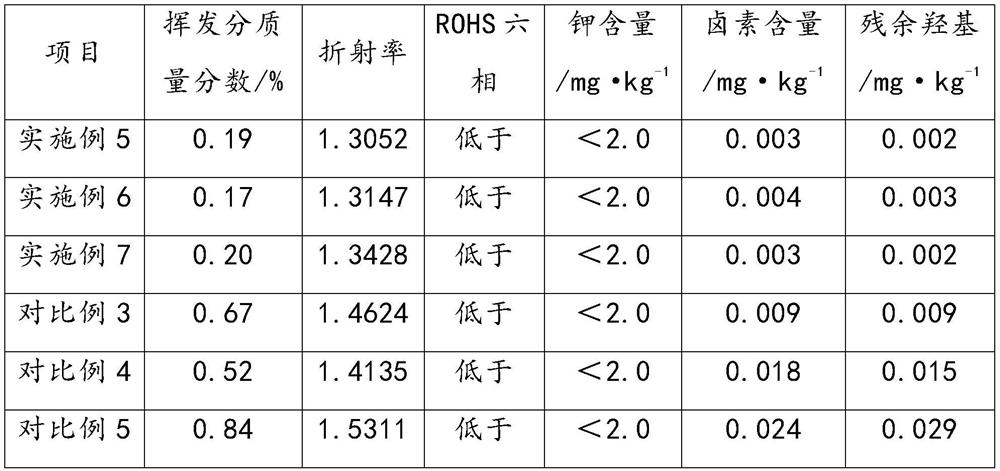

Examples

Embodiment 1

[0030] The present embodiment provides a kind of composite deamination agent, which is made by the following steps:

[0031] Step C1, put 0.1 mol of chloromethyl triazole, 0.1 mol of sodium ethoxide, and 100 mL of absolute ethanol in a three-necked flask, stir and react at 70 °C for 8 h under nitrogen protection, then add 0.1 mol of KH-550, and heat up to reflux for 24 h , filtered, and the filtrate was distilled under reduced pressure to remove dehydrated alcohol to obtain Intermediate 1;

[0032] Step C2: Mix 0.11 mol of intermediate 1, 0.11 mol of 3-propane sultone and 100 mL of absolute ethanol, stir at 50 °C for 8 h, add dropwise 12.3 mL of sulfuric acid solution with a concentration of 0.1 mol / L, and stir the reaction at 50 °C 12h, washed with anhydrous ether for three times, then distilled under reduced pressure to remove ethanol and ether to obtain Intermediate 2;

[0033] In step C3, 0.4 g of intermediate 2, 1 g of attapulgite and 100 mL of anhydrous toluene were pla...

Embodiment 2

[0035] The present embodiment provides a kind of composite deamination agent, which is made by the following steps:

[0036] Step C1, put 0.1 mol of chloromethyl triazole, 0.1 mol of sodium ethoxide, and 120 mL of absolute ethanol in a three-necked flask, stir and react at 70 °C for 8 h under nitrogen protection, then add 0.1 mol of KH-550, and heat up to reflux for 24 h , filtered, and the filtrate was distilled under reduced pressure to remove dehydrated alcohol to obtain Intermediate 1;

[0037] Step C2: Mix 0.11 mol of Intermediate 1, 0.11 mol of 3-propane sultone and 120 mL of absolute ethanol, stir at 50 °C for 8 h, dropwise add 13.5 mL of sulfuric acid solution with a concentration of 0.1 mol / L, and stir at 50 °C for reaction 12h, washed with anhydrous ether for three times, then distilled under reduced pressure to remove ethanol and ether to obtain Intermediate 2;

[0038] Step C3, put 0.6 g of intermediate 2, 1 g of attapulgite and 100 mL of anhydrous toluene in a th...

Embodiment 3

[0042] The present embodiment provides a solid catalyst, which is made by the following steps:

[0043] Step B1: Stir and mix 1 g of diatomaceous earth and 2.5 mL of deionized water for 20 minutes, add 0.5 mL of a 15% sulfuric acid solution, stir and react at 100°C for 4 hours, then add deionized water to dilute to 4 times the original volume, and continue The reaction was stirred for 1 hour, and then filtered. The filter cake was washed with deionized water until the washing liquid became neutral, dried at 100 °C for 4 hours, and calcined at 600 °C for 2 hours to obtain acidified diatomaceous earth;

[0044] Step B2: Dissolve zirconium oxychloride in distilled water, add acidified diatomaceous earth, irradiate with microwave for 3 minutes in a microwave oven with a power of 450W, then dry at 110°C, pre-bake at 700°C for 2 hours, and then use sulfuric acid with a concentration of 0.1mol / L. The solution was immersed for 1h, the liquid-solid ratio was 15mL / g during immersion, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com