Glass powder for main gate electrode silver paste of TOPCon battery as well as preparation method and application of glass powder

A busbar electrode and glass powder technology, which is applied in glass manufacturing equipment, glass furnace equipment, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of poor solderability, poor wettability of aluminum and lead-tin solder strips, Reliability discount and other issues, to achieve the effect of low lap resistance and high aging adhesion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0044] Step 1. Glass powder is prepared according to the following steps:

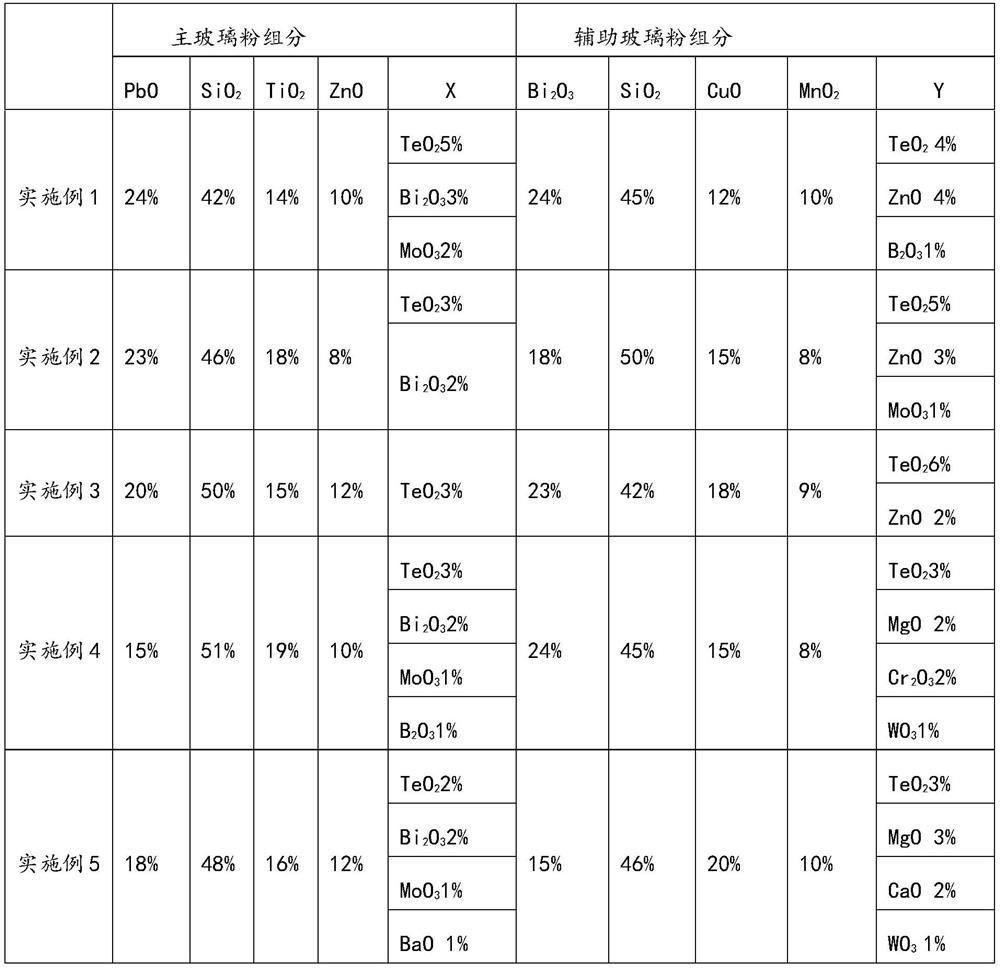

[0045] (1) According to Table 1, the raw materials of the main glass powder and the auxiliary glass powder are respectively placed in a three-dimensional mixer and mixed evenly;

[0046] (2) Place the uniformly mixed raw materials in an alumina crucible, and melt at 1300°C for 60 minutes;

[0047] (3) Use a double-roll mill to roll the melted glass melt into flakes, use a pulverizer to pulverize the rolled glass flakes, and then use a vibrating sieving machine to sieve the pulverized glass powder. Grinding, polishing and grading the vibrating and sifted glass powder to obtain the required main glass powder and auxiliary glass powder.

[0048] Step 2. The busbar silver paste is prepared according to the following steps:

[0049] (1) take the butyl carbitol of solvent 10% by mass percentage, with 33% butyl carbitol acetate, 14% diethylene glycol dibutyl ether, 15% tripropylene glycol monomethyl ether, ...

Embodiment 6

[0056] Other steps are identical with embodiment 1, and difference only is that solvent is a single alcohol fat twelve.

Embodiment 7

[0058] Other steps are the same as in Example 1, except that the solvent is a single diethylene glycol dibutyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com