Cross-scale core-shell structure aluminum-based composite material and preparation method thereof

A technology of core-shell structure and aluminum-based composite materials, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low plasticity matching, low efficiency of complex stress transfer, and agglomeration of reinforcements, so as to disperse stress concentration and solve problems The effect of low plastic matching degree and relieving interfacial pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

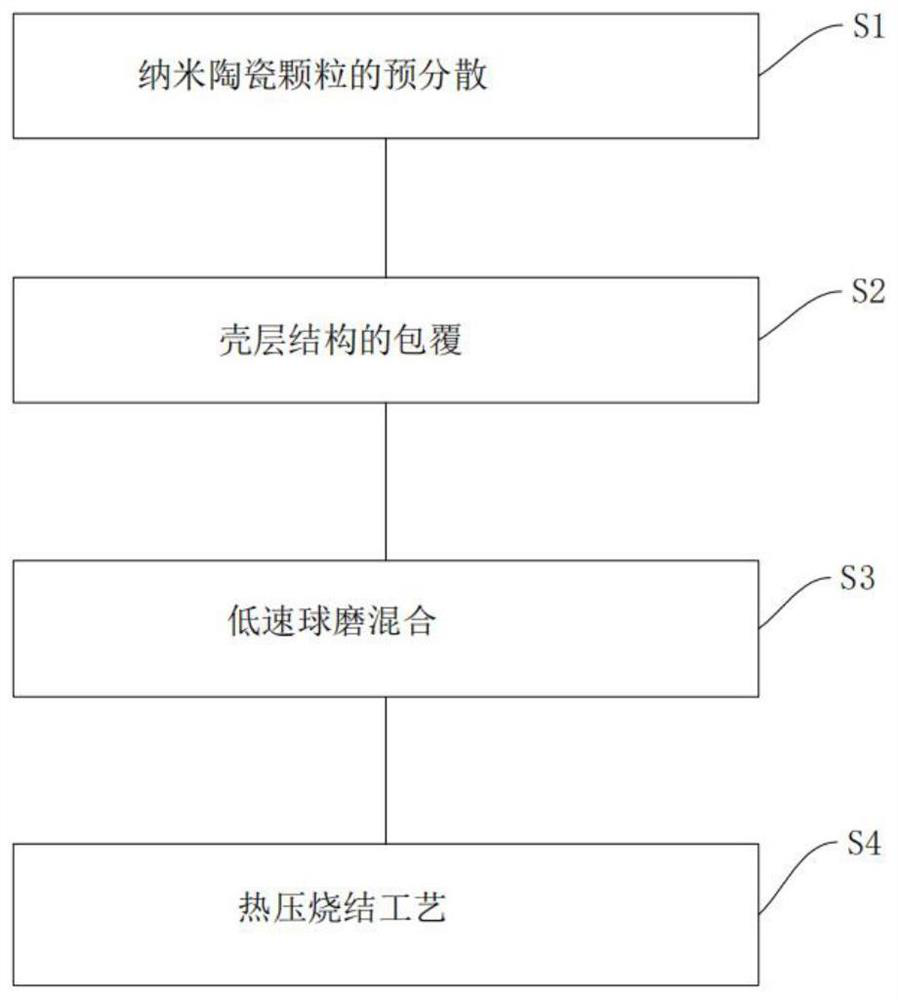

[0030] Such as figure 1 Shown: The preparation method of the cross-scale core-shell structure aluminum matrix composite material provided by the embodiment of the present invention includes:

[0031] S1: Pre-dispersion of nano-ceramic particles: pre-disperse nano-scale SiC particles and hundreds of nano-sized Al powder;

[0032] S2: Coating of shell structure: use high-speed ball milling method to embed the pre-dispersed powder in S1 on the surface of micron hard ceramic particles to form a shell structure;

[0033] S3: Low-speed ball milling and mixing: uniformly ball-milling the reinforcement powder element with a shell structure and the aluminum alloy matrix powder to form a hybrid reinforced composite alloy powder;

[0034] S4: hot pressing sintering process, the hybrid reinforced composite alloy powder is processed by hot pressing sintering process to obtain cross-scale core-shell structure aluminum matrix composites.

[0035] In the above-mentioned embodiment, firstly,...

Embodiment 1

[0042] (1) Pre-dispersion of nano-ceramic particles: select 3.5vol.%-5.5vol.% nano-scale SiC particles, 4.5vol.%-5.5vol.% 100-nanometer-sized Al powder, and the oxidation of large, medium and small sizes Zirconium balls are made of an asteroid ball mill with a speed of 200-320r / min, and the ball milling time is 2-4 hours, so that the nano-hard SiC particles can be deagglomerated and evenly mixed with the flexible Al powder to achieve the purpose of pre-dispersion.

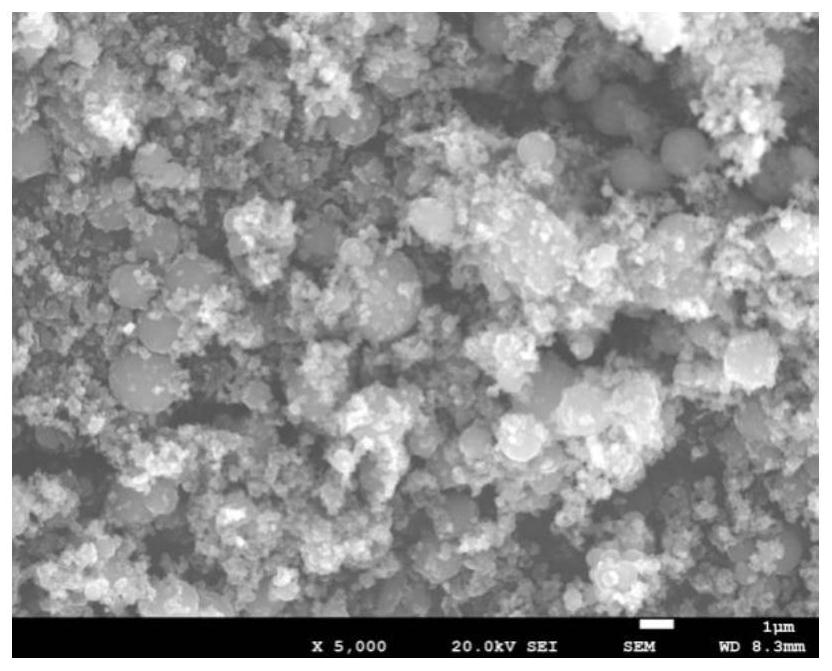

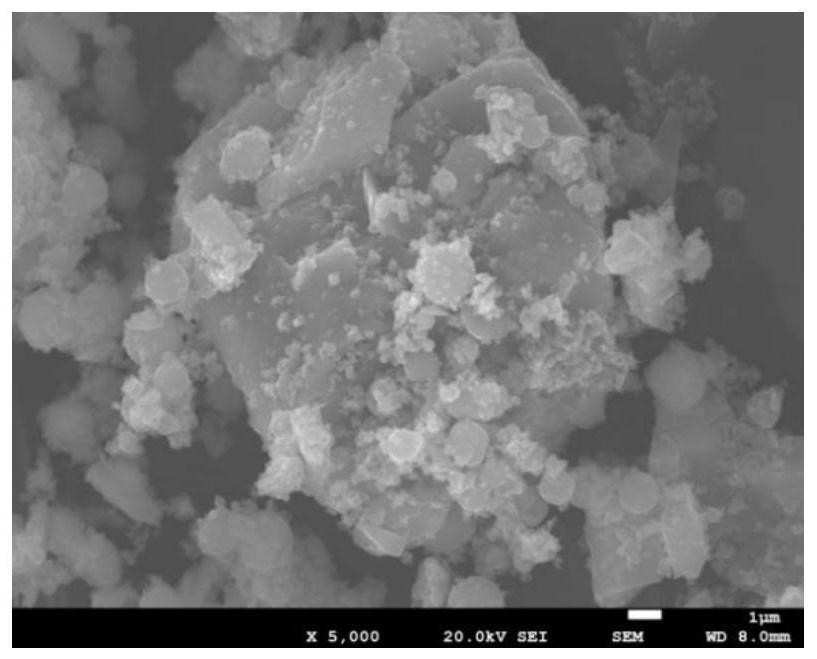

[0043] (2) Coating of shell structure: In order to form a specific shell structure, the pre-dispersed powder is "embedded" on the surface of micron hard ceramic particles by high-speed ball milling. Use the speed of 600-1200r / min to carry out high-speed ball milling. The ball milling environment is anhydrous ethanol liquid environment. The ball milling time is 30min (short time high energy). Put the mixed powder slurry in a drying box at a temperature of 80°C Dry for 8 hours to obtain reinforcement powder with shel...

Embodiment 2

[0047] (1) Select 3.0vol.% 80nm SiC ceramic particles and 5.0vol.% 800nm pure Al spherical powder, mix different sizes of zirconia balls in a certain proportion, and mix them in a liquid environment of 99.8% high-purity anhydrous ethanol, Pour into a 500mL zirconia ball mill jar. Choose an asteroid ball mill, use a speed of 300r / min, and mill for 3 hours. After the uniformly mixed powder slurry is sieved to remove the balls, put it in a glass crystallization dish, and dry it in a vacuum oven at a drying temperature of 80°C. Drying in the middle, the drying time lasts 8h. A pre-dispersed mixed shell structure powder is obtained.

[0048] (2) Take the above mixed pre-dispersed shell structure powder, add 5vol.% 12μm SiC ceramic particles, and a certain proportion of mixed zirconia balls, pour them into a 500mL zirconia ball mill jar, add 250mL 99.8% High-purity absolute ethanol forms a liquid ball milling environment. High-speed ball milling is carried out at a speed of 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com