Phase change material cold compress patch

A technology of phase change materials and organic phases, applied in heat exchange materials, cooling appliances for therapeutic treatment, chemical instruments and methods, etc., can solve the problems of slow cooling speed, slow cold therapy process, high phase transition temperature, etc. , to achieve the effect of improving the ability to absorb heat, efficiently cooling biological tissues, and high efficiency of cold compress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the low temperature eutectic phase change material comprises the following steps:

[0057] Use a precision electronic balance to weigh the organic phase change material according to the mass ratio, and mix and grind the thickener with a total mass ratio of 0.5%~1%. After heating until completely melted, keep the temperature constant, use magnetic stirring for 25-30 minutes, then add 1% of the total mass of emulsifier, continue heating and magnetic stirring for 10-15 minutes, take it out, and cool it at room temperature to obtain a low-temperature eutectic phase change material .

[0058] Preferably, the magnetic stirring speed in the manufacturing step is 300 r / min.

[0059] In the low-temperature eutectic phase change material of the present invention, because the main component used is an organic phase change material, the degree of supercooling is small, and the phase separation phenomenon is not as remarkable as that of the inorganic phase...

Embodiment 1

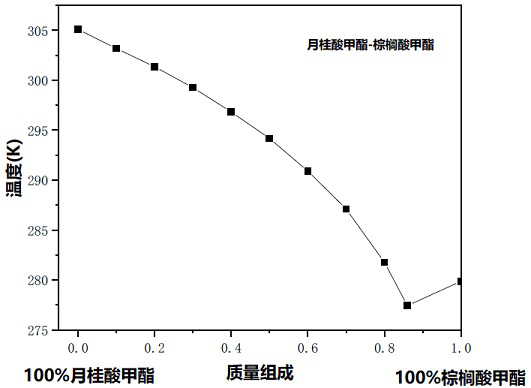

[0076] An organic eutectic phase change material prepared from methyl laurate (98%) and methyl palmitate (98%) without further purification. According to the mass ratio of methyl laurate to methyl palmitate M1:M2=90:10;80:20;70:30;60:40;50:50;40:60;30:70;20:80;10: 90 were doped to obtain nine groups of samples, by Calculate the eutectic point of the eutectic phase change material of methyl laurate and methyl palmitate, the calculation results are as follows figure 1 , which shows that the best mass ratio of methyl laurate to methyl palmitate M1:M2=68:32 is obtained at the eutectic point of 13°C. The latent heat of phase change, the calculation result is 178J / g, which makes it suitable for the corresponding needs. After weighing, put the thickener gelatin into a magnetic stirring pot and heat and stir above the melting point of the phase change material. After 30 minutes, add the emulsifier sodium lauryl sulfate and use magnetic stirring for 10 minutes, then cool to room tem...

Embodiment 2

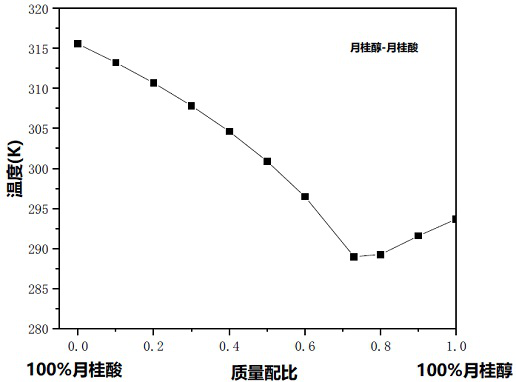

[0078] An organic eutectic phase change material, prepared by lauric acid (98%) and lauryl alcohol (98%), repeating the steps in Example 1, the calculation results are as follows figure 2 Shown, made in mass ratio (28:72), phase transition point (15°C) and melting enthalpy (183 J / g). Get PCM15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com