Heat-conducting gel and preparation method thereof

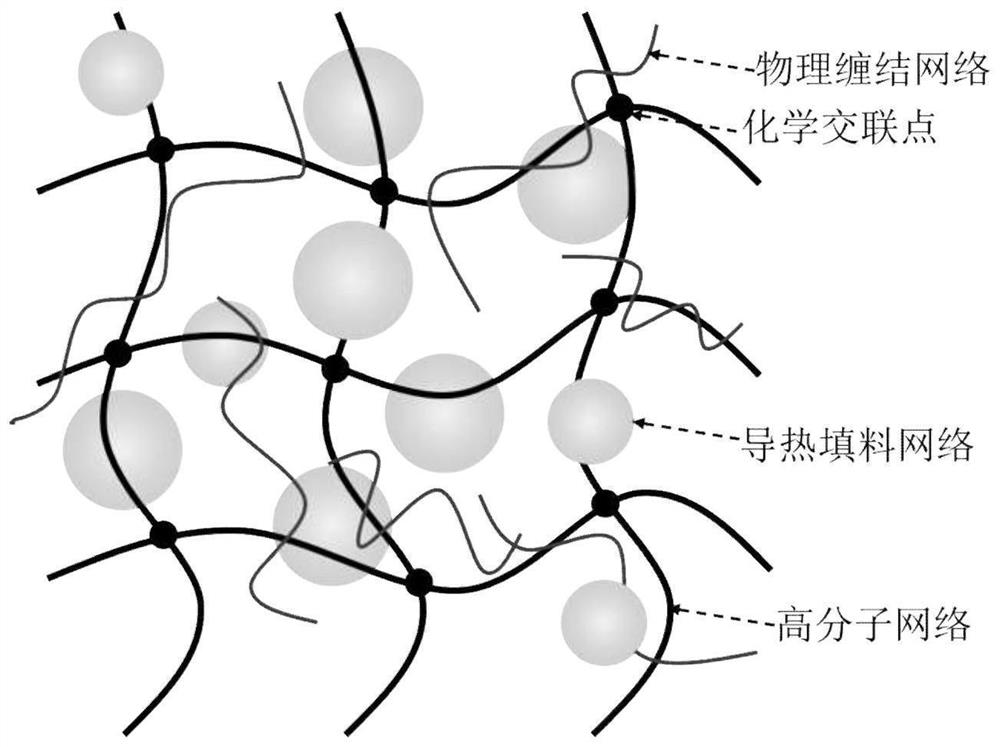

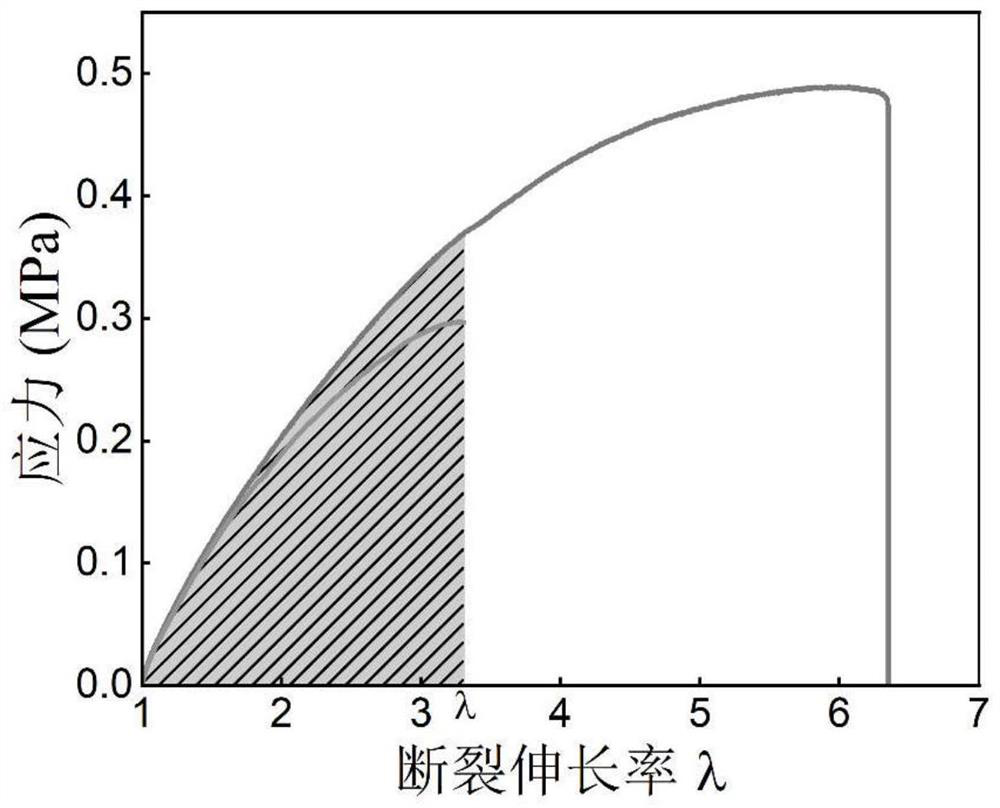

A gel and heat-conducting filler technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of less heat-conducting gels, ignoring thermal conductivity, and not paying attention to contact thermal resistance, etc., to achieve high thermal conductivity and Low thermal contact resistance and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

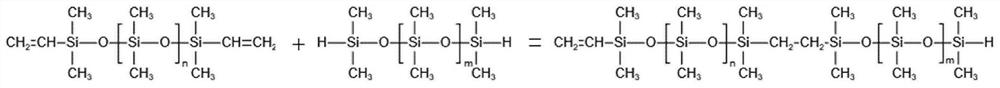

Method used

Image

Examples

Embodiment 1

[0071] (1) The mass ratio of silicone oil prepolymer and other silicone oil is 3:2, and the mass ratio of silicone oil prepolymer and other silicone oil to filler is 1:9. Silicone oil prepolymer (9g) and side chain vinyl silicone oil (1.38g) with mass average molecular weight 5000, vinyl content 0.3255mmol / g, double-ended vinyl silicone oil with mass average molecular weight 10000, vinyl content 0.2047mmol / g (0.74g), double-ended hydrogen-containing silicone oil (3.88g) with a mass average molecular weight of 20000 and a hydrogen content of 0.1028mmol / g, aluminum oxide (67.5g) with a particle diameter of 20 μm, aluminum (33.75g) with a particle diameter of 15 μm, Zinc oxide (33.75g) and 2-phenyl-3-butyl-2-hexanol (0.01g) with a particle size of 0.3μm were added to a 0.5L double planetary mixer; under a vacuum of -90.0kPa, at a speed of 50rpm , stirring for 2.0h;

[0072] (2) Add chloroplatinic acid-isopropanol complex (0.05g), under the condition of vacuum degree -90.0kPa, 15...

Embodiment 2

[0074] The preparation process of the thermally conductive gel in this example is the same as in Example 1, except that the ratio of the mass of the silicone oil prepolymer to the sum of the side chain vinyl silicone oil, the double-ended vinyl silicone oil, and the double-ended hydrogen-containing silicone oil is 1:1, the specific preparation process is as follows:

[0075] (1) Mix silicone oil prepolymer (7.5g) with side chain vinyl silicone oil (1.725g) with mass average molecular weight of 5000 and vinyl content of 0.3255mmol / g; Terminal vinyl silicone oil (0.925g), double-ended hydrogen-containing silicone oil (4.85g) with a mass average molecular weight of 20000 and a hydrogen content of 0.1028mmol / g, a particle diameter of 20 μm alumina (67.5g), a particle diameter of 15 μm aluminum ( 33.75g), zinc oxide (33.75g) and 2-phenyl-3-butyl-2-hexanol (0.01g) with a particle size of 0.3μm were added to a 0.5L double planetary mixer; under a vacuum of -90.0kPa, Stir for 2.0h at...

Embodiment 3

[0079] The preparation process of the thermally conductive gel in this example is the same as in Example 1, except that the ratio of the mass of the silicone oil prepolymer to the sum of the side chain vinyl silicone oil, the double-ended vinyl silicone oil, and the double-ended hydrogen-containing silicone oil is The specific preparation process of 2:3 is as follows:

[0080] (1) Silicone oil prepolymer (6g) and side chain vinyl silicone oil (2.07g) with a mass average molecular weight of 5000 and a vinyl content of 0.3255mmol / g, and a double-ended Vinyl silicone oil (1.11g), double-ended hydrogen-containing silicone oil (5.82g) with a mass average molecular weight of 20000 and a hydrogen content of 0.1028mmol / g, aluminum oxide (67.5g) with a particle diameter of 20 μm, aluminum (33.75 g) with a particle diameter of 15 μm g), zinc oxide (33.75g) and 2-phenyl-3-butyl-2-hexanol (0.01g) with a particle size of 0.3 μm are added to a 0.5L double planetary mixer; under a vacuum of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com